How to measure bolt pattern on a wheel is a fundamental skill for anyone looking to replace or upgrade their vehicle’s wheels. Understanding bolt pattern ensures proper wheel fitment, promoting safety and optimal performance. This comprehensive guide delves into the intricacies of bolt pattern measurement, encompassing the essential components, measurement techniques, and interpretation of results. By mastering these techniques, you’ll gain the confidence to choose the right wheels for your vehicle, ensuring a secure and smooth ride.

The bolt pattern, often referred to as the lug pattern, represents the arrangement of the lug holes on a wheel. It’s a crucial aspect of wheel compatibility, dictating whether a wheel will fit your vehicle’s hub. The bolt pattern consists of three key elements: the diameter of the circle formed by the lug holes, the number of lug holes, and the location of the studs or bolts.

A common bolt pattern for many vehicles is 5×114.3, indicating five lug holes arranged on a circle with a diameter of 114.3 millimeters.

Understanding Bolt Pattern Basics

The bolt pattern is a crucial aspect of wheel compatibility, ensuring a secure and proper fit for your vehicle. Understanding the intricacies of bolt patterns can save you from potential damage and ensure a smooth ride.

Components of a Bolt Pattern

The bolt pattern defines the arrangement of lug holes on a wheel, specifying the distance between them and their positioning. It comprises three key components:

- Diameter: The diameter refers to the circle that passes through the centers of all the lug holes. It is measured in inches or millimeters, and it determines the overall size of the bolt pattern.

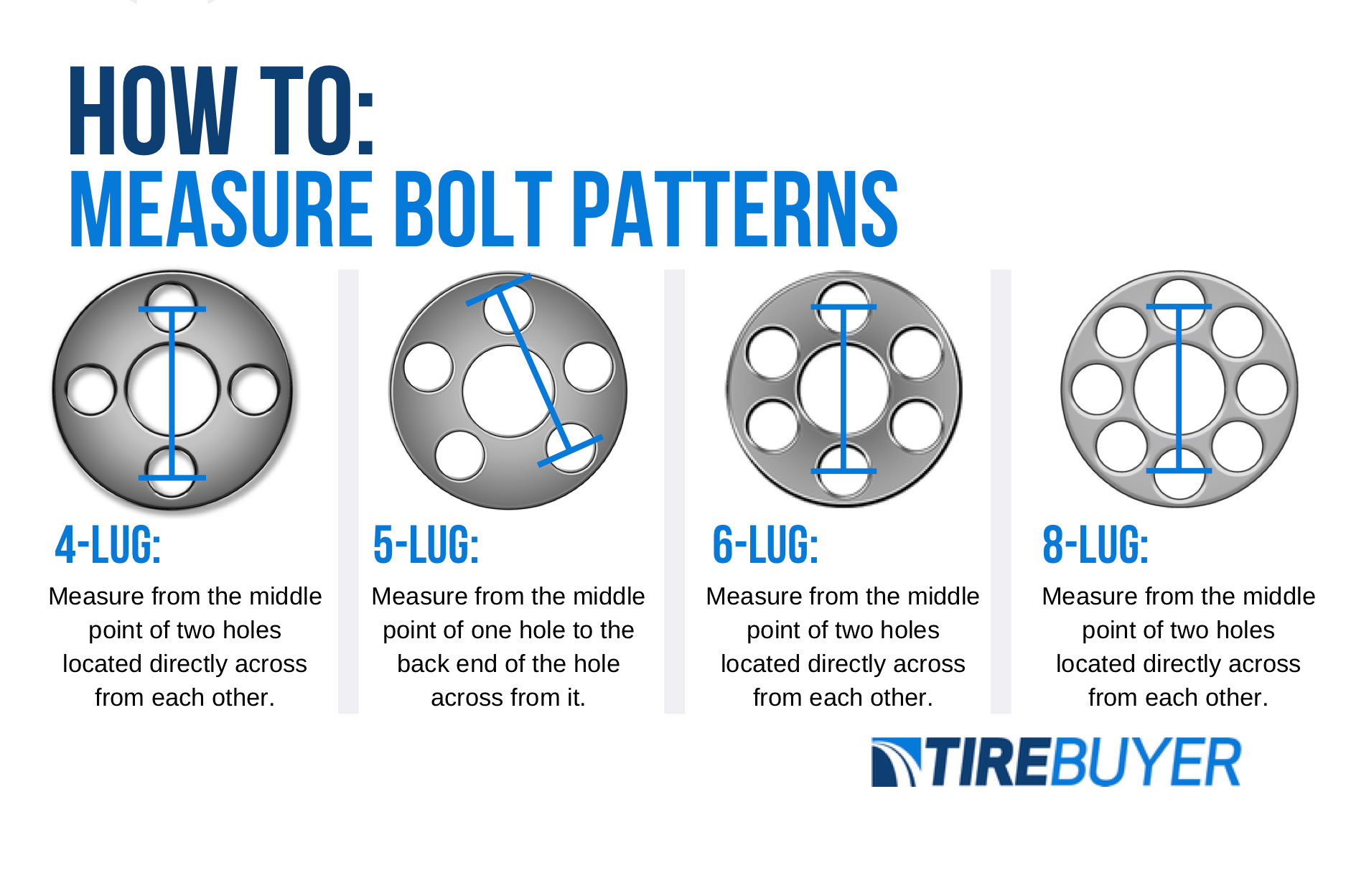

- Number of Lug Holes: This refers to the number of studs or bolts that hold the wheel to the hub. The most common number of lug holes is five, but some vehicles may have four, six, or even eight.

- Stud Location: This refers to the position of the lug holes relative to each other. It is often described as a pattern, such as 5×114.3, where “5” represents the number of lug holes and “114.3” represents the diameter in millimeters.

Common Bolt Patterns and Vehicle Types

Different vehicle manufacturers use specific bolt patterns for their models. Some common bolt patterns and their corresponding vehicle types are listed below:

| Bolt Pattern | Vehicle Types |

|---|---|

| 5×100 | Honda, Toyota, Mazda, Subaru |

| 5×114.3 | Toyota, Honda, Nissan, Mazda |

| 5×120 | BMW, Mercedes-Benz, Audi |

| 5×130 | Ford, Chevrolet, Dodge |

| 6×139.7 | Toyota, Ford, Chevrolet, Dodge |

For instance, a 5×114.3 bolt pattern indicates that the wheel has five lug holes spaced equally around a circle with a diameter of 114.3 millimeters.

Measuring the Bolt Pattern

Now that you understand the basics of bolt patterns, it’s time to get your hands dirty and measure your wheel. This process is straightforward and requires only a few simple tools. Let’s delve into the steps.

Identifying the Center of the Wheel Hub

The center of the wheel hub is the starting point for measuring the bolt pattern. It’s the point where the wheel is attached to the vehicle. * Visual Inspection: Look at the wheel hub. You’ll likely see a raised area or a small protrusion in the center. This is usually a small metal nipple, sometimes called a “center hub” or “center cap.”

Measuring Tape

Use a measuring tape to measure the distance from the edge of the hub to the center. This will help you locate the exact center.

Calipers

If you have calipers, use them to measure the diameter of the hub. Divide this diameter by two to get the radius, which is the distance from the center to the edge of the hub.

Locating the Lug Holes

Once you’ve identified the center of the hub, you can locate the lug holes, which are the holes where the lug nuts attach. * Visual Inspection: The lug holes are usually evenly spaced around the hub. They should be clearly visible.

Measuring Tape

Use a measuring tape to measure the distance between two adjacent lug holes. This measurement will be used to determine the bolt pattern.

Interpreting the Measurement

Now that you’ve diligently measured the distance between the bolt holes and the diameter of the circle they form, it’s time to decode the information you’ve gathered. Understanding the language of bolt patterns will allow you to identify the perfect wheel for your vehicle.

Common Bolt Pattern Formats

The measured values reveal the bolt pattern in a specific format. Let’s dive into the common formats and their interpretations.

- 5×114.3: This format signifies a bolt pattern with five bolts arranged on a circle with a diameter of 114.3 millimeters. This is a popular pattern found on many vehicles, particularly Japanese and Korean models.

- 4×100: This format indicates a pattern with four bolts on a circle with a diameter of 100 millimeters. It’s frequently seen on smaller vehicles and older models.

- 5×120: This format features five bolts on a circle with a diameter of 120 millimeters. This pattern is common on many European vehicles.

Interpreting the Bolt Pattern

To interpret the bolt pattern, consider the following:

- Number of Bolts: The first number in the format represents the number of bolts on the wheel.

- Bolt Circle Diameter (BCD): The second number signifies the diameter of the circle formed by the bolt holes, typically measured in millimeters.

Example: A bolt pattern of 5×114.3 indicates a wheel with five bolts arranged in a circle with a diameter of 114.3 millimeters.

Precision and Accuracy

Precise and accurate measurements are crucial when determining bolt patterns. Even a slight error can lead to incompatibility between the wheel and the vehicle, potentially causing safety hazards. Use a measuring tape or caliper to ensure your measurements are as precise as possible.

Bolt Pattern Compatibility

Bolt pattern compatibility is paramount for safe and proper wheel installation. Using incompatible wheels can lead to severe consequences, jeopardizing your safety and vehicle’s integrity.

Understanding Bolt Pattern Compatibility, How to measure bolt pattern on a wheel

Understanding bolt pattern compatibility is crucial for safe and proper wheel installation. A mismatch in bolt patterns can lead to a variety of issues, including:

- Wheel Wobble: An incompatible bolt pattern can cause the wheel to wobble, leading to an uncomfortable ride and potential damage to the suspension.

- Wheel Separation: In the worst-case scenario, an incompatible bolt pattern can cause the wheel to separate from the vehicle while driving, leading to a catastrophic accident.

- Improper Wheel Fitment: Using an incompatible bolt pattern can result in the wheel not seating properly on the hub, leading to uneven wear and tear on the tires and suspension.

- Stress on Wheel Studs: An incompatible bolt pattern can put undue stress on the wheel studs, potentially leading to breakage.

Common Bolt Patterns

The following table lists common bolt patterns for various vehicle makes and models:

| Make | Model | Bolt Pattern |

|---|---|---|

| Honda | Civic | 4×100 |

| Toyota | Camry | 5×114.3 |

| Ford | Mustang | 5×114.3 |

| Chevrolet | Silverado | 6×139.7 |

| Jeep | Wrangler | 5×127 |

Note: It is always recommended to consult your vehicle’s owner’s manual or a reliable online resource to confirm the correct bolt pattern for your specific vehicle.

Additional Considerations

While the bolt pattern is a crucial factor in wheel compatibility, it’s only one piece of the puzzle. Ensuring a safe and proper fit requires considering additional factors like wheel offset and hub bore. These elements play a vital role in determining how the wheel sits on the vehicle and how it interacts with the hub.

Wheel Offset

Wheel offset, often denoted as ET, refers to the distance between the wheel mounting surface and the center of the wheel. A positive offset indicates the mounting surface is closer to the outer edge of the wheel, while a negative offset places it closer to the inner edge. Understanding offset is critical because it affects how the wheel sits within the wheel well, influencing factors like tire clearance, suspension travel, and vehicle handling.

Hub Bore

The hub bore is the diameter of the central hole in the wheel that fits over the vehicle’s hub. A wheel with a hub bore that is too small will not fit properly over the hub, while one that is too large can lead to instability and potential damage. Ensuring the hub bore of the new wheels matches that of your vehicle is essential for a secure and safe fit.

Identifying Compatible Wheels

Leveraging online resources and databases can streamline the process of finding compatible wheels. Numerous websites and tools allow you to input your vehicle’s make, model, and year to retrieve a list of compatible wheels. These resources often include details about bolt pattern, offset, and hub bore, simplifying the search for the right fit.

Wheel Compatibility Checklist

Before purchasing new wheels, it’s essential to consider a comprehensive checklist to ensure a smooth and safe installation:

- Bolt Pattern: The number of lug holes and their spacing must match the vehicle’s specifications.

- Wheel Offset (ET): The offset should be within the recommended range for your vehicle.

- Hub Bore: The hub bore of the new wheels must match that of your vehicle.

- Wheel Diameter: The wheel diameter should be compatible with your vehicle’s tire size and suspension system.

- Wheel Width: The wheel width should be within the recommended range for your vehicle and tire size.

- Load Rating: The wheel’s load rating must be equal to or greater than the vehicle’s maximum axle load.

Measuring bolt pattern on a wheel is a straightforward process that requires attention to detail and the right tools. By carefully following the steps Artikeld in this guide, you’ll be able to determine the correct bolt pattern for your vehicle and select compatible wheels. Remember to prioritize safety and always consult with a qualified mechanic if you have any doubts or concerns.

With a clear understanding of bolt pattern and proper wheel selection, you can confidently enhance your vehicle’s style and performance while ensuring a secure and enjoyable driving experience.

FAQ Insights: How To Measure Bolt Pattern On A Wheel

What is the significance of bolt pattern compatibility?

Bolt pattern compatibility is essential for safe and proper wheel installation. Using incompatible wheels can lead to loose or misaligned wheels, increasing the risk of accidents and compromising vehicle stability.

Can I use a wheel with a different bolt pattern than my vehicle?

No, using a wheel with a different bolt pattern than your vehicle is extremely dangerous and should be avoided. The wheel may not fit securely on the hub, potentially leading to catastrophic failure.

What are some common bolt patterns for different vehicle makes and models?

Common bolt patterns vary depending on the vehicle make and model. Some common patterns include 5×100, 5×114.3, 5×120, and 6×139.7. It’s best to consult your vehicle’s owner’s manual or a reliable online database to determine the specific bolt pattern for your car.

What are some online resources for finding compatible wheels?

Several online resources and databases can help you identify compatible wheels based on your vehicle’s make, model, and bolt pattern. Popular options include Tire Rack, Discount Tire, and Wheel Hero.