Do you cut patterns on the wrong side of fabric? This might seem like a simple question, but the answer holds the key to creating beautifully finished garments. Understanding the difference between the right and wrong side of fabric is crucial for any sewing project, whether you’re a seasoned seamstress or just starting out. Cutting on the wrong side can lead to unexpected wrinkles, fabric distortion, and even a complete change in the final appearance of your creation.

Let’s dive into the world of fabric sides and learn how to cut patterns correctly for stunning results.

This article will guide you through the process of identifying the right side of various fabric types, offering tips for accurate pattern placement and cutting techniques. We’ll also explore common mistakes and how to avoid them, ensuring you achieve professional-looking results with every project.

Understanding Fabric Sides

It’s crucial to know the difference between the right and wrong sides of fabric when sewing. This knowledge ensures that your finished garment looks its best and that you’re using the fabric correctly.

Identifying Fabric Sides

The right side of a fabric is typically the side that is meant to be seen, while the wrong side is hidden. Fabrics often have a different appearance on each side, with the right side having a more finished look.

- Printed Fabrics: The right side usually features the print or pattern, while the wrong side may be plain or have a slightly different color.

- Woven Fabrics: The right side often has a smoother texture and a more consistent weave than the wrong side, which may have a looser weave or visible threads.

- Knit Fabrics: The right side of a knit fabric typically has a smoother, more even surface than the wrong side, which may have a more textured or bumpy appearance.

Implications of Cutting Patterns on the Wrong Side

Cutting patterns on the wrong side of the fabric can have several negative consequences:

- Incorrect Grain Line: The grain line, which is the direction of the fabric’s threads, is crucial for a garment’s fit and drape. Cutting on the wrong side can result in an incorrect grain line, leading to distortions and unevenness.

- Visible Seams: Seams on the wrong side of the fabric can be visible on the right side, especially if the fabric is thin or has a contrasting color.

- Poor Finish: The right side of the fabric is usually the one that receives finishing touches, such as pressing or topstitching. Cutting on the wrong side can make these finishing touches less effective or even impossible.

Why Cutting on the Wrong Side Matters

Cutting fabric on the wrong side can significantly impact the final appearance, drape, and even the durability of your sewing project. While it may seem like a minor detail, choosing the correct side for cutting can make a world of difference in the outcome of your garment or craft.

Impact on Appearance and Drape

The right side of fabric is often the side that features the print, pattern, or texture intended for display. Cutting on the wrong side can result in a garment with an uneven or reversed pattern, a duller color, or a less desirable texture. For example, cutting a patterned fabric on the wrong side could lead to a garment with the pattern facing inward, hidden from view.

Similarly, cutting a fabric with a nap (a directional texture) on the wrong side can cause the nap to run in the wrong direction, affecting the drape and overall appearance of the garment.

Fabric Shrinkage and Distortion

Some fabrics, particularly those made from natural fibers like cotton or linen, are prone to shrinkage. Cutting on the wrong side can exacerbate this issue, as the wrong side is often less tightly woven and may shrink more than the right side. This can lead to a garment that is too small or distorted after washing. Additionally, cutting on the wrong side can sometimes affect the fabric’s ability to stretch or drape properly, especially with fabrics that have a distinct right and wrong side, like velvet or satin.

Identifying the Right Side

Identifying the right side of fabric is crucial for accurate pattern placement and a professional-looking finished product. This is especially important when working with patterned fabrics, as the design should be displayed on the intended side.

There are several ways to determine the right side of fabric. Understanding the fabric type, examining the selvedge, checking for texture differences, and observing the pattern can all help you make the right decision.

Common Fabric Types and Their Distinctive Features

Different fabric types often have distinct features that can help identify the right side. Here’s a breakdown of some common fabrics and their distinguishing characteristics:

- Cotton: Cotton fabrics are often smoother and brighter on the right side, with a more pronounced weave. The wrong side may appear slightly duller and have a less defined weave.

- Silk: Silk fabrics are typically known for their lustrous, smooth finish on the right side. The wrong side may feel slightly rougher or have a more matte appearance.

- Linen: Linen fabrics have a characteristic uneven texture, with the right side often exhibiting a more pronounced slubby look. The wrong side may appear smoother and less textured.

- Velvet: Velvet fabrics have a distinct pile that creates a soft, plush texture on the right side. The wrong side, known as the “back” of the velvet, is typically smooth and flat.

- Brocade: Brocade fabrics are characterized by intricate woven patterns that stand out more prominently on the right side. The wrong side may have a less defined pattern or a more subdued appearance.

- Satin: Satin fabrics have a smooth, lustrous finish on the right side, often with a subtle sheen. The wrong side is typically matte and less reflective.

- Denim: Denim fabrics have a distinctive diagonal twill weave. The right side, often referred to as the “face” of the denim, has a smoother texture and a more pronounced twill pattern. The wrong side, known as the “back” of the denim, is typically rougher and has a less defined twill pattern.

Identifying the Right Side Using Fabric Features

Besides fabric type, several other clues can help you determine the right side of your fabric:

- Selvedge: The selvedge is the tightly woven edge of the fabric that runs along the length of the fabric. It’s often thicker and more textured than the rest of the fabric. The right side of the fabric is usually the side facing the selvedge.

- Texture: Some fabrics have a noticeable difference in texture between the right and wrong sides. The right side may be smoother, softer, or have a more defined weave than the wrong side.

- Pattern: If the fabric has a pattern, the right side will typically display the pattern in its intended orientation. The wrong side may show the pattern in reverse or have a less defined appearance.

Comparing Fabric Types and Identification Methods, Do you cut patterns on the wrong side of fabric

The following table summarizes the different fabric types and their corresponding right side identification methods:

| Fabric Type | Right Side Identification |

|---|---|

| Cotton | Smoother, brighter, more pronounced weave |

| Silk | Lustrous, smooth finish |

| Linen | Uneven texture, more pronounced slubby look |

| Velvet | Soft, plush pile |

| Brocade | Intricate woven patterns |

| Satin | Smooth, lustrous finish with subtle sheen |

| Denim | Smoother texture, more pronounced twill pattern |

Cutting Techniques for Accuracy

Precise pattern placement is crucial for achieving a well-fitting and professional-looking garment. Even a slight misalignment can result in a distorted final product. Therefore, taking the time to ensure accurate pattern placement before cutting is essential.

Marking the Fabric

Marking the fabric with tailor’s chalk or pins before cutting is a crucial step in ensuring accuracy. This helps you visualize the pattern pieces on the fabric and avoid any accidental cuts in the wrong place.

- Tailor’s Chalk: Tailor’s chalk comes in various colors and is ideal for marking fabric. It easily washes away after sewing, leaving no permanent marks. When using tailor’s chalk, ensure you press lightly to avoid creating deep lines that might show through the fabric.

- Pins: Pins are essential for securing pattern pieces to the fabric, especially when working with slippery materials. Always use sharp pins to avoid tearing the fabric. Place pins perpendicular to the cutting line, ensuring they don’t obstruct the path of your cutting tool.

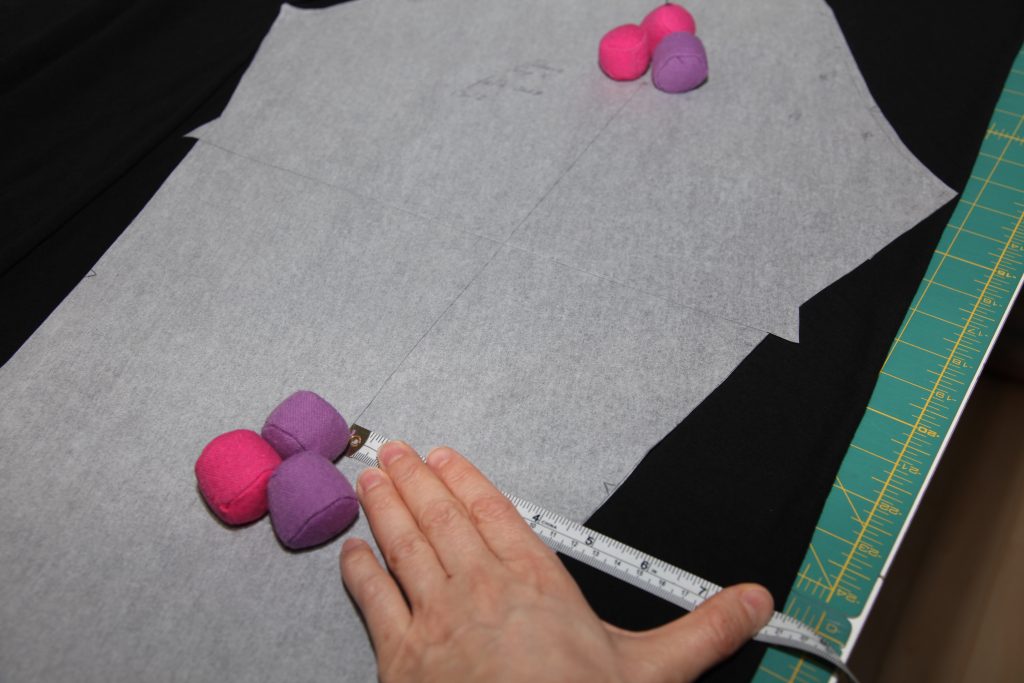

Using a Rotary Cutter and Cutting Mat

For precise and efficient fabric cutting, a rotary cutter and cutting mat are invaluable tools. They provide a controlled and smooth cutting experience, reducing the risk of fabric slippage and uneven cuts.

- Rotary Cutter: A rotary cutter is a circular blade housed in a handle. It allows for smooth and precise cutting along straight lines and curves. Ensure the blade is sharp for clean cuts.

- Cutting Mat: A cutting mat is a self-healing surface designed to protect your work surface and prevent damage to your cutting tools. It provides a stable and non-slip surface for cutting.

Avoiding Common Mistakes

While cutting patterns on the wrong side of fabric offers numerous benefits, it’s essential to be aware of potential pitfalls to avoid ruining your fabric or pattern. By understanding common mistakes and implementing preventative measures, you can ensure accurate cutting and achieve professional-looking results.

Identifying and Preventing Common Mistakes

It’s crucial to recognize common mistakes that can arise when cutting patterns on the wrong side of fabric. This section will explore these mistakes and offer practical solutions to prevent them.

- Cutting Through Pattern Markings: Accidentally cutting through pattern markings, such as seam allowances or darts, is a common mistake. To avoid this, use a contrasting fabric marker to trace the pattern onto the wrong side of the fabric. This allows you to see the pattern markings clearly and prevent accidental cuts.

- Cutting Into the Seam Allowance: Cutting too close to the pattern line and accidentally cutting into the seam allowance can lead to garments that are too small or have uneven seams. To prevent this, use a rotary cutter and a ruler to ensure accurate cutting along the seam allowance line. Additionally, it’s helpful to use a clear ruler with a grid pattern to visualize the seam allowance and ensure precise cutting.

- Misaligned Fabric Layers: When cutting multiple fabric layers simultaneously, ensuring they are perfectly aligned is crucial. If the layers are misaligned, the resulting garment will have uneven seams and a distorted fit. To prevent misalignment, use a cutting mat with a grid pattern to ensure all fabric layers are aligned before cutting. Additionally, use weights or pins to secure the fabric layers in place during cutting.

- Using Dull Cutting Tools: Dull cutting tools can lead to inaccurate cuts and fraying fabric edges. To prevent this, use sharp rotary cutters, scissors, or a sharp blade. It’s essential to sharpen or replace dull tools regularly to maintain accurate cutting.

- Inadequate Fabric Support: Cutting fabric on a hard surface without proper support can result in uneven cuts and fabric slippage. To prevent this, use a cutting mat or a sturdy, flat surface to support the fabric during cutting. Additionally, use a cutting board or a piece of plywood to provide additional support and stability.

Preventing Accidental Cuts Into the Seam Allowance

Cutting into the seam allowance is a common mistake that can lead to a poorly fitting garment. To prevent this, it’s crucial to understand the concept of seam allowance and use accurate cutting techniques.

- Understanding Seam Allowance: The seam allowance is the extra fabric surrounding the pattern lines, which is used for sewing seams. It’s important to understand the standard seam allowance for different garment types and to always cut along the seam allowance line.

- Using a Rotary Cutter and Ruler: A rotary cutter and ruler combination offers excellent precision for cutting along the seam allowance line. This method ensures accurate cutting and minimizes the risk of cutting into the seam allowance.

- Using a Clear Ruler with a Grid Pattern: A clear ruler with a grid pattern helps visualize the seam allowance and ensures accurate cutting. This visual aid is particularly useful for beginners or those who find it challenging to cut precisely.

- Using a Seam Allowance Template: Seam allowance templates are readily available and offer a convenient way to cut consistent seam allowances. These templates are typically made of plastic or metal and can be used with a rotary cutter or scissors.

Armed with the knowledge of fabric sides and cutting techniques, you’re ready to conquer any sewing project with confidence. Remember, taking the time to identify the right side of your fabric and using precise cutting methods will make a world of difference in the final look and feel of your creations. So, grab your fabric, patterns, and sharp scissors, and let’s get sewing!

Questions and Answers: Do You Cut Patterns On The Wrong Side Of Fabric

What if I accidentally cut a pattern piece on the wrong side of the fabric?

Don’t panic! If you’ve already cut a pattern piece on the wrong side, you can still salvage it. You can either re-cut the piece on the right side or use the wrong side as a lining. Just make sure to account for the difference in texture and appearance when making your decision.

Is there a foolproof way to identify the right side of fabric?

While there are general guidelines, some fabrics can be tricky. If you’re unsure, it’s always best to check the manufacturer’s label or consult a fabric store associate for guidance.

Do I need to use a rotary cutter for precise cutting?

While a rotary cutter is a great tool for accurate and efficient cutting, you can also achieve precise results with sharp fabric scissors. The key is to use a cutting mat and a ruler to guide your cuts.

Can I cut multiple layers of fabric at once?

Yes, you can cut multiple layers of fabric at once, but it’s important to ensure that the layers are evenly stacked and held securely in place to avoid shifting or uneven cuts.