How to secure shed to ground – Ever felt like your shed was just a gust of wind away from becoming a tumbleweed? Well, hold onto your hard-earned tools, because we’re about to secure that shed like it’s the last piece of pizza at a party. From hurricane-proof anchors to DIY solutions, we’re diving into the world of shed security, so you can relax knowing your stuff is safe and sound.

Think of your shed as your personal mini-warehouse, a sanctuary for your tools, bikes, or maybe even a secret stash of snacks. But without proper anchoring, it’s just a flimsy box begging for trouble. We’ll cover everything from the basics of choosing the right anchoring system to the nitty-gritty of installation. By the time you’re done, you’ll be a shed-securing pro, ready to face any weather or would-be thief head-on.

Understanding the Importance of Securing a Shed to the Ground

Imagine a powerful storm rolling through your neighborhood. Strong winds whip through the trees, and heavy rain batters the ground. In this scenario, a shed that isn’t properly secured could easily become a victim of the elements. The force of the wind could lift it off the ground, sending it crashing into your property or your neighbor’s.

This is just one reason why securing your shed to the ground is crucial.

The Risks and Consequences of an Unsecured Shed

An unsecured shed is a magnet for trouble. Here’s why:

- Damage from Wind and Weather: As mentioned earlier, strong winds can easily lift an unsecured shed, causing damage to the shed itself, your property, and even nearby structures. Heavy rain can seep into the shed, causing damage to your belongings. Snow accumulation on the roof can also lead to collapse.

- Theft: A shed that’s not secured to the ground is an easy target for thieves. They can simply lift it onto a truck and drive away with your valuable belongings. Even if the shed isn’t stolen, thieves might break in to steal the contents, leaving you with a damaged shed and a loss of valuable items.

- Safety Hazards: An unsecured shed can become a safety hazard. Children playing near the shed could accidentally bump into it, causing it to fall over. If the shed is located near a walkway, it could become a tripping hazard. In the event of a storm, a flying shed could injure people or damage property.

Real-World Examples of Shed Damage and Theft

There are numerous real-world examples of sheds being damaged or stolen due to lack of proper anchoring. For example, in 2023, a strong storm swept through the Midwest, leaving a trail of destruction in its wake. Many sheds in the affected areas were lifted off the ground and damaged, causing thousands of dollars in losses for homeowners. In another instance, a homeowner in California reported that his shed was stolen from his backyard.

The thieves simply lifted it onto a truck and drove away. These examples highlight the importance of securing your shed to the ground to prevent damage and theft.

Methods for Securing a Shed to the Ground

Securing your shed to the ground is crucial for its stability and longevity, especially in areas prone to strong winds or harsh weather conditions. A well-secured shed will prevent it from being blown over or lifted by the wind, protecting your belongings and ensuring the structural integrity of the shed.

Concrete Anchor Bolts

Concrete anchor bolts are a reliable and durable method for securing a shed to the ground. This method involves drilling holes into the concrete foundation and inserting bolts with expansion sleeves or epoxy resin.

- Advantages: Concrete anchor bolts are extremely strong and provide a secure hold. They are resistant to weathering and can withstand heavy loads.

- Disadvantages: This method requires drilling into concrete, which can be challenging and time-consuming. It also requires specialized tools and equipment.

- Materials: Concrete anchor bolts, drill, hammer drill, masonry drill bits, measuring tape, level, safety goggles, and work gloves.

- Estimated Cost: $20-$50 per anchor bolt.

Steps for Installing Concrete Anchor Bolts:

- Determine the location of the anchor bolts. Use a level to mark the locations on the concrete foundation where you want to install the anchor bolts. Ensure that the anchor bolts are placed at strategic points to provide maximum stability.

- Drill holes into the concrete foundation. Use a hammer drill and a masonry drill bit to drill holes at the marked locations. The depth of the holes should be slightly deeper than the length of the anchor bolt.

- Insert the anchor bolts. Insert the anchor bolts into the holes. If using expansion sleeves, hammer them into place until they are flush with the concrete. If using epoxy resin, follow the manufacturer’s instructions for mixing and application.

- Secure the shed to the anchor bolts. Use heavy-duty bolts or lag screws to connect the shed’s frame to the anchor bolts. Ensure that the connections are tight and secure.

Ground Anchors

Ground anchors, also known as earth anchors, are a popular choice for securing sheds to the ground. These anchors are driven into the ground using a sledgehammer or specialized driving tool.

- Advantages: Ground anchors are relatively easy to install and require minimal tools. They are also a cost-effective option compared to other anchoring methods.

- Disadvantages: Ground anchors may not be as strong as concrete anchor bolts, especially in loose or sandy soil. They can also be susceptible to corrosion over time.

- Materials: Ground anchors, sledgehammer, driving tool, measuring tape, level, safety goggles, and work gloves.

- Estimated Cost: $10-$30 per anchor.

Steps for Installing Ground Anchors:

- Determine the location of the ground anchors. Use a level to mark the locations on the ground where you want to install the ground anchors. Ensure that the anchors are placed at strategic points to provide maximum stability.

- Drive the ground anchors into the ground. Use a sledgehammer or driving tool to drive the anchors into the ground until they are securely embedded. The depth of the anchors will depend on the type of soil and the weight of the shed.

- Secure the shed to the ground anchors. Use heavy-duty bolts or lag screws to connect the shed’s frame to the ground anchors. Ensure that the connections are tight and secure.

Tie-Downs

Tie-downs are straps or cables that are attached to the shed’s frame and secured to ground anchors or concrete blocks. They are often used in conjunction with other anchoring methods to provide additional stability.

- Advantages: Tie-downs are easy to install and can be adjusted as needed. They are also relatively inexpensive.

- Disadvantages: Tie-downs may not be as strong as other anchoring methods, especially in high-wind areas. They can also be susceptible to wear and tear over time.

- Materials: Tie-down straps or cables, ground anchors or concrete blocks, heavy-duty bolts or lag screws, measuring tape, level, safety goggles, and work gloves.

- Estimated Cost: $5-$20 per tie-down.

Steps for Installing Tie-Downs:

- Determine the location of the tie-downs. Use a level to mark the locations on the shed’s frame and the ground where you want to install the tie-downs. Ensure that the tie-downs are placed at strategic points to provide maximum stability.

- Attach the tie-downs to the shed’s frame. Use heavy-duty bolts or lag screws to secure the tie-downs to the shed’s frame. Ensure that the connections are tight and secure.

- Secure the tie-downs to ground anchors or concrete blocks. Use heavy-duty bolts or lag screws to secure the tie-downs to ground anchors or concrete blocks. Ensure that the connections are tight and secure.

Table Comparing Anchoring Techniques:

| Technique | Pros | Cons | Materials | Estimated Cost |

|---|---|---|---|---|

| Concrete Anchor Bolts | Extremely strong, durable, weather-resistant | Requires drilling into concrete, specialized tools | Concrete anchor bolts, drill, hammer drill, masonry drill bits, measuring tape, level, safety goggles, work gloves | $20-$50 per anchor bolt |

| Ground Anchors | Easy to install, cost-effective, minimal tools required | May not be as strong as concrete anchor bolts, susceptible to corrosion | Ground anchors, sledgehammer, driving tool, measuring tape, level, safety goggles, work gloves | $10-$30 per anchor |

| Tie-Downs | Easy to install, adjustable, inexpensive | May not be as strong as other methods, susceptible to wear and tear | Tie-down straps or cables, ground anchors or concrete blocks, heavy-duty bolts or lag screws, measuring tape, level, safety goggles, work gloves | $5-$20 per tie-down |

Choosing the Right Anchoring System

Selecting the right anchoring system for your shed is crucial to ensure its stability and longevity. This decision involves considering several factors that influence the effectiveness and suitability of the anchoring system.

Factors to Consider

The selection of an anchoring system depends on several factors, including:

- Shed Size and Weight: Larger and heavier sheds require stronger anchoring systems to withstand higher wind loads and potential ground movement.

- Soil Type: Different soil types have varying load-bearing capacities. For instance, clay soils provide excellent support, while sandy soils may require additional reinforcement.

- Local Weather Conditions: High winds, heavy rainfall, and snow loads can significantly impact the anchoring system’s performance.

- Shed Foundation: The type of foundation used for the shed influences the anchoring method. Concrete foundations offer greater stability and allow for more robust anchoring options.

Recommendations for Specific Anchoring Systems

Here are some recommendations for specific anchoring systems based on different shed types and locations:

- Small Sheds (Less Than 100 Square Feet) on Firm Ground: Concrete blocks or heavy-duty stakes driven into the ground can provide sufficient anchoring.

- Medium-Sized Sheds (100-200 Square Feet) on Firm Ground: Consider using a combination of stakes and concrete anchors for enhanced stability.

- Large Sheds (Over 200 Square Feet) or Sheds on Loose Soil: Concrete piers or helical anchors offer superior strength and resistance to ground movement.

Examples of Successful Anchoring Systems

- For a 10×12 foot shed on clay soil: A combination of four concrete anchors and six heavy-duty stakes driven into the ground provided excellent stability during a heavy windstorm.

- For a 12×16 foot shed on sandy soil: Helical anchors installed around the perimeter of the shed effectively prevented movement during a severe rainstorm.

- For a 16×24 foot shed on a concrete foundation: Concrete piers poured into the ground and attached to the shed’s foundation ensured maximum stability and resistance to ground movement.

Materials and Tools Required

Securing your shed to the ground is a crucial step in ensuring its stability and longevity. This process involves a combination of materials and tools, each playing a vital role in creating a secure foundation for your shed. Let’s delve into the specifics of what you’ll need to get the job done right.

Materials

The materials required for securing a shed to the ground depend on the chosen anchoring system. Here’s a breakdown of common materials, their functions, and tips for selecting high-quality options:

- Concrete Anchors: Concrete anchors are a popular choice for securing sheds, particularly those made of heavier materials. These anchors are typically made of steel or galvanized metal and come in various sizes and shapes.

- Size: The size of the concrete anchor should be appropriate for the weight of your shed and the type of soil. Consult a local building code for recommended anchor sizes based on your shed’s weight and soil conditions.

- Material: Opt for galvanized steel anchors, which offer superior resistance to corrosion, ensuring long-term durability in outdoor environments.

- Concrete Mix: Concrete is used to secure anchors to the ground. Choose a pre-mixed concrete mix that is designed for outdoor use and meets local building code requirements.

- Strength: The strength of the concrete mix should be appropriate for the weight of your shed and the soil conditions. For most sheds, a standard concrete mix with a compressive strength of 3,000 psi is sufficient.

- Water-to-Cement Ratio: Follow the manufacturer’s instructions regarding the water-to-cement ratio for the specific mix you’ve chosen. Too much water can weaken the concrete, while too little can make it difficult to work with.

- Post Anchors: Post anchors are designed to secure wooden posts or beams to the ground. These anchors are typically made of metal and come in various shapes, including L-shaped, T-shaped, and U-shaped.

- Size: The size of the post anchor should be appropriate for the size of the post or beam you are securing. Consider the weight of the shed and the soil conditions when selecting the anchor size.

- Material: Galvanized steel post anchors offer superior corrosion resistance, ensuring long-term durability in outdoor environments.

- Metal Straps: Metal straps are used to connect the shed’s frame to the anchoring system. They are typically made of galvanized steel and come in various widths and thicknesses.

- Width: The width of the strap should be sufficient to cover the width of the shed’s frame. Consider the size and weight of the shed when selecting the strap width.

- Thickness: The thickness of the strap should be sufficient to withstand the stresses placed on it. A thicker strap will provide greater strength and durability.

- Lag Screws: Lag screws are used to attach the metal straps to the shed’s frame and to the anchoring system. They are typically made of galvanized steel and come in various lengths and diameters.

- Length: The length of the lag screw should be sufficient to penetrate through the shed’s frame and into the anchoring system. Consider the thickness of the shed’s frame and the size of the anchor when selecting the screw length.

- Diameter: The diameter of the lag screw should be appropriate for the size of the hole in the shed’s frame and the anchoring system. A larger diameter screw will provide greater holding power.

- Caulk: Caulk is used to seal gaps between the shed’s frame and the anchoring system, preventing water infiltration. Choose a caulk that is designed for outdoor use and is compatible with the materials used in your shed.

- Type: Silicone caulk is a popular choice for outdoor use, as it is flexible, durable, and water-resistant.

- Color: Select a caulk color that blends with the shed’s exterior to maintain a cohesive appearance.

Tools

Having the right tools will make the process of securing your shed to the ground much easier and more efficient. Here are some essential tools to have on hand:

- Measuring Tape: A measuring tape is essential for accurately measuring the dimensions of your shed and the distances between anchor points.

- Level: A level is used to ensure that the shed is installed level, which is important for stability and preventing water damage.

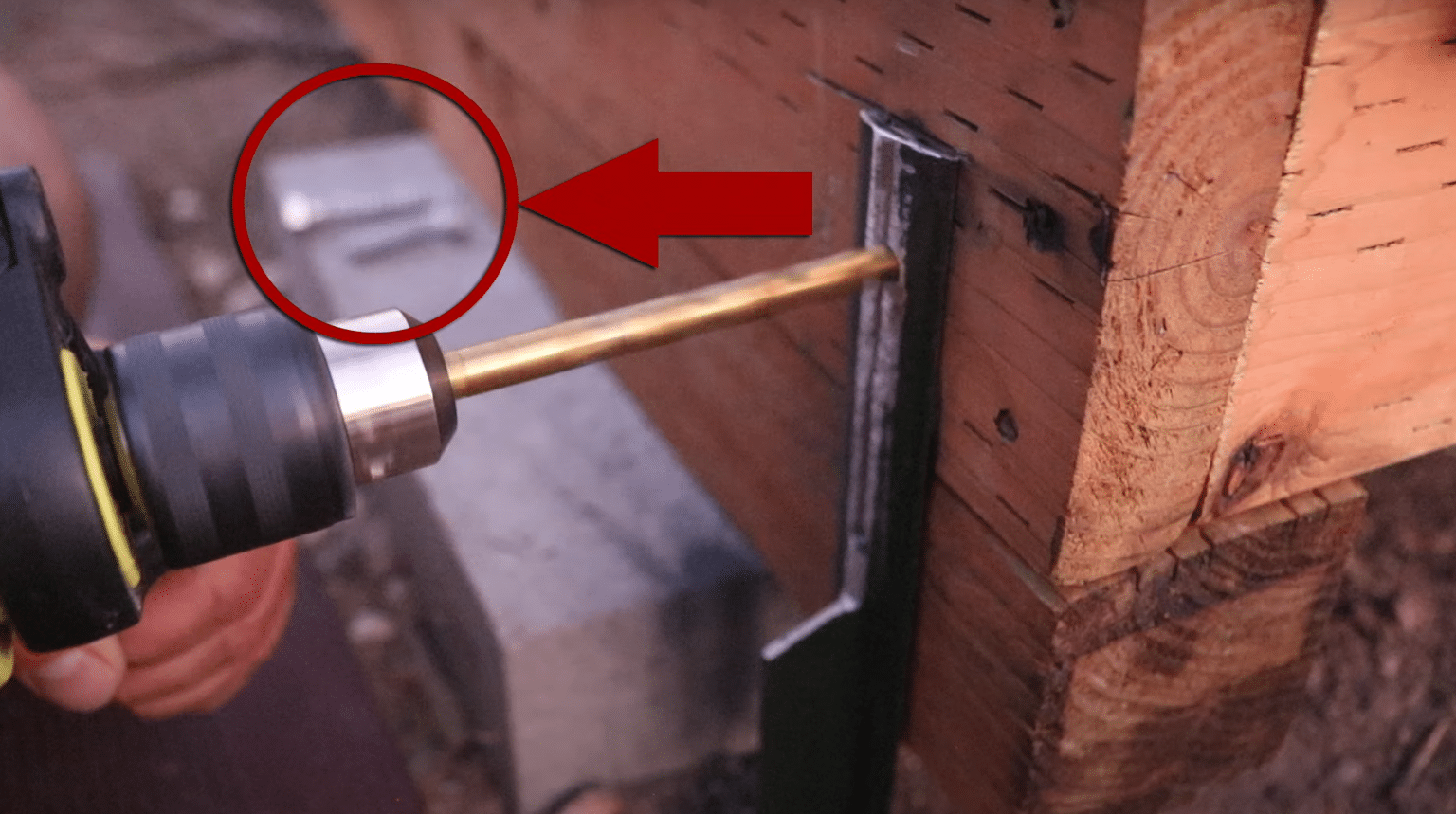

- Drill: A drill is used to create holes for the anchors and to attach the metal straps to the shed’s frame. Choose a drill with a variable speed setting to control the drilling speed and prevent damage to the wood.

- Hammer: A hammer is used to drive the concrete anchors into the ground and to secure the metal straps to the shed’s frame.

- Shovel: A shovel is used to dig the holes for the concrete anchors. Use a shovel with a comfortable grip and a sturdy blade.

- Post Hole Digger: A post hole digger is a specialized tool that can make digging holes for anchors much easier. Choose a post hole digger with a comfortable grip and a durable blade.

- Wrench: A wrench is used to tighten the nuts on the concrete anchors and the lag screws that attach the metal straps to the shed’s frame.

- Safety Glasses: Safety glasses protect your eyes from flying debris while drilling and hammering.

- Work Gloves: Work gloves protect your hands from splinters and other hazards while working with wood and metal.

- Hearing Protection: Hearing protection is essential when using power tools, especially a drill, to protect your ears from loud noise.

Safety First: Always prioritize safety when working on a project like securing a shed. Wear appropriate safety gear, including safety glasses, work gloves, and hearing protection. Follow all manufacturer instructions for the tools and materials you are using.

Installation Process

Installing shed anchors can seem daunting, but with the right tools and a little patience, you can create a secure and stable foundation for your shed. This section will guide you through the step-by-step process using concrete anchors as an example. Remember, accuracy and precision are crucial for a successful installation.

Preparing the Site

Before starting, clear the area around your shed where you will be installing the anchors. Remove any debris, rocks, or vegetation. This ensures that the anchor will be firmly seated on solid ground.

- Mark the locations for your anchors. These should correspond to the designated anchor points on your shed’s base. Use stakes and string to create a clear Artikel.

- Dig holes for the anchors. Use a post hole digger or a shovel to excavate holes at each marked location. The depth of the holes should be slightly deeper than the length of the anchor.

- Level the bottom of the holes. This ensures the anchors are seated evenly and provides a stable base.

Installing the Anchors

Once the holes are prepared, you can begin installing the anchors.

- Position the anchors in the holes. Make sure they are aligned with the marked points and that the top of the anchor is flush with the ground.

- Fill the holes with concrete. Mix concrete according to the manufacturer’s instructions. Pour the concrete into the holes, ensuring it completely surrounds the anchor.

- Tamp the concrete. Use a tamper or a piece of wood to compact the concrete around the anchor. This helps to eliminate air pockets and ensure a solid bond.

- Level the concrete. Use a trowel or a level to ensure the top of the concrete is even with the ground.

Securing the Shed

After the concrete has cured, you can secure the shed to the anchors.

- Attach the shed’s base to the anchors. This can be done using bolts, lag screws, or other appropriate fasteners. Make sure the fasteners are long enough to penetrate the concrete and secure the shed firmly.

- Tighten the fasteners. Use a wrench or a drill to tighten the fasteners until the shed is securely attached to the anchors.

Additional Tips

- Consider using a post-hole digger to create holes for your anchors. This will help to ensure that the holes are the correct depth and diameter.

- Mix the concrete according to the manufacturer’s instructions. This will ensure that the concrete is the correct consistency and will cure properly.

- Use a tamper to compact the concrete around the anchors. This will help to eliminate air pockets and ensure a solid bond.

- Level the concrete before it sets. This will ensure that the anchors are seated evenly and provide a stable base.

- Allow the concrete to cure for at least 24 hours before securing the shed to the anchors. This will give the concrete time to harden and reach its full strength.

“A secure shed is a happy shed!”

Maintenance and Inspection: How To Secure Shed To Ground

Just like any other part of your shed, the anchoring system needs regular maintenance and inspection to ensure it continues to do its job effectively. Neglecting this crucial aspect can lead to a weakened anchoring system, leaving your shed vulnerable to damage or even collapse.

Regular Inspections

Regular inspections are essential for identifying any potential issues before they escalate into major problems. Here’s a checklist to guide your inspections:

- Check for signs of damage: Look for cracks, breaks, or any other visible damage to the anchoring components.

- Inspect for corrosion: Pay attention to the metal parts of the anchoring system. Corrosion can weaken the metal, making it less effective.

- Verify tightness: Ensure that all bolts, nuts, and other fasteners are securely tightened. Looseness can lead to the anchoring system failing to hold the shed in place.

- Examine the surrounding soil: Look for any signs of erosion or movement in the soil around the anchoring system. This could indicate instability that could compromise the anchoring system’s effectiveness.

Repairing and Replacing Damaged Components

If you discover any damage during your inspections, it’s important to address it promptly.

- Minor repairs: For minor damage, like cracks or scratches, you can often repair them with epoxy or other suitable adhesives.

- Replacement: If the damage is more significant, like a broken bolt or a corroded anchor, it’s necessary to replace the damaged component.

- Professional help: For complex repairs or replacements, it’s best to consult with a professional contractor to ensure the work is done correctly and safely.

Remember, a well-maintained anchoring system is essential for the safety and longevity of your shed. Regular inspections and prompt repairs can help you prevent costly damage and ensure your shed remains secure for years to come.

Safety Considerations

Securing your shed to the ground is an important step in protecting your belongings and ensuring the structural integrity of your shed. However, it is crucial to prioritize safety during the installation process. By taking necessary precautions and using appropriate safety equipment, you can minimize risks and ensure a safe and successful project.

Potential Hazards and Safety Precautions

The installation process involves working with tools and materials that can pose potential hazards if not handled correctly. Here are some common hazards and safety precautions to mitigate risks:

Working at Heights

- Always use a stable ladder or scaffolding when working at heights.

- Ensure the ladder or scaffolding is securely positioned on level ground and properly secured.

- Never overreach or stand on the top rung of a ladder.

- Use a safety harness and lanyard if working at heights exceeding 6 feet.

Heavy Lifting

- Use proper lifting techniques to avoid strain or injury.

- Bend your knees and lift with your legs, keeping your back straight.

- Ask for help when lifting heavy objects, especially if working alone.

- Use lifting aids, such as dollies or hoists, whenever possible.

Power Tools

- Always wear safety glasses to protect your eyes from flying debris.

- Use gloves to protect your hands from cuts and abrasions.

- Keep power tools clean and in good working condition.

- Disconnect power tools from the power source before making adjustments or cleaning them.

- Never operate power tools while standing on a wet surface.

Sharp Objects

- Use caution when handling sharp objects, such as shovels, picks, and screwdrivers.

- Wear heavy-duty gloves to protect your hands from cuts.

- Store sharp objects in a safe place when not in use.

Excavation

- Be aware of underground utilities, such as gas lines, electrical cables, and water pipes.

- Contact your local utility companies to mark the location of underground utilities before digging.

- Use caution when excavating near existing structures or foundations.

Weather Conditions

- Avoid working in extreme weather conditions, such as heavy rain, snow, or high winds.

- If working in hot weather, take frequent breaks to avoid heat exhaustion.

Safety Equipment, How to secure shed to ground

Wearing appropriate safety equipment is crucial to minimize risks and ensure a safe working environment. Here are some essential items to have on hand:

- Safety Glasses: Protect your eyes from flying debris and dust.

- Gloves: Protect your hands from cuts, abrasions, and chemical exposure.

- Protective Footwear: Steel-toe boots or work shoes provide protection for your feet.

- Hearing Protection: Earplugs or earmuffs can reduce noise levels from power tools.

- Safety Harness and Lanyard: Essential for working at heights exceeding 6 feet.

So, there you have it – the ultimate guide to turning your shed from a potential disaster zone into a fortress of your belongings. Remember, a secure shed is a happy shed, and a happy shed means a happy you. Go forth, conquer the world of shed anchoring, and enjoy the peace of mind that comes with knowing your stuff is safe and sound.

And hey, if you ever need a helping hand, we’re always here to lend a wrench.

Questions Often Asked

What if my shed is on a concrete slab?

No worries! You can use concrete anchors or heavy-duty bolts to secure your shed to the slab. Just make sure to drill pilot holes and use the appropriate size fasteners.

Can I anchor my shed myself?

Absolutely! Many anchoring methods are relatively simple and can be done with basic tools and a little bit of DIY know-how. Just make sure to follow the instructions carefully and don’t hesitate to call in a pro if you need extra help.

How often should I check my shed’s anchoring system?

It’s a good idea to check your shed’s anchors at least once a year, especially after harsh weather conditions. Look for any signs of damage, corrosion, or loosening. If you see any problems, get them fixed right away.