Do you ever adjust valve clearance on v strom – Do you ever adjust valve clearance on a V-Strom? This question is essential for any V-Strom owner who wants to ensure their motorcycle runs smoothly and efficiently. Valve clearance is crucial for the proper operation of your engine, and neglecting it can lead to serious problems. This article will guide you through the basics of valve clearance, the adjustment procedure, and the importance of regular maintenance.

We’ll explore the consequences of incorrect valve clearance, the tools and materials needed for adjustment, and the recommended intervals for checking and adjusting valve clearance. Whether you’re a seasoned rider or a novice, understanding valve clearance is essential for keeping your V-Strom running at its best.

We’ll also delve into troubleshooting common valve clearance issues and offer expert advice on how to ensure your V-Strom receives the best care. From understanding the symptoms of incorrect valve clearance to identifying potential causes and troubleshooting tips, this comprehensive guide will equip you with the knowledge to keep your V-Strom performing at its peak.

V-Strom Valve Clearance Basics

Valve clearance is a crucial aspect of motorcycle engine performance, ensuring the proper functioning of the valves and optimal combustion. It’s the small gap between the valve stem and the rocker arm, allowing the valve to open and close freely.

Importance of Valve Clearance

Valve clearance plays a vital role in engine performance and longevity. It allows the valves to open and close properly, ensuring efficient combustion and preventing damage to the engine components.

- Optimal Combustion: Proper valve clearance ensures that the valves open and close at the correct times, allowing the appropriate amount of air and fuel to enter the combustion chamber. This leads to efficient combustion and optimal engine power output.

- Valve Seat Contact: When the valve is closed, it needs to rest firmly against the valve seat. Adequate clearance ensures that the valve doesn’t hit the seat, preventing wear and tear. This maintains the seal between the combustion chamber and the intake/exhaust manifold.

- Valve Train Wear: Correct clearance minimizes friction between the valve stem and the rocker arm, reducing wear and tear on the valve train components. This contributes to the longevity of the engine.

Consequences of Incorrect Valve Clearance

Incorrect valve clearance can lead to a range of problems, affecting engine performance, fuel efficiency, and longevity.

- Reduced Engine Power: Insufficient clearance can prevent the valves from opening fully, restricting airflow and reducing engine power output. This can also lead to incomplete combustion, resulting in lower fuel efficiency.

- Valve Damage: Too much clearance can cause the valve to bounce off the rocker arm, resulting in valve damage. This can lead to engine failure and costly repairs.

- Increased Engine Noise: Incorrect valve clearance can cause the engine to run noisily, with tapping or clicking sounds, indicating that the valves are not opening and closing properly.

- Premature Wear: Incorrect clearance can lead to increased wear and tear on the valve train components, reducing engine longevity.

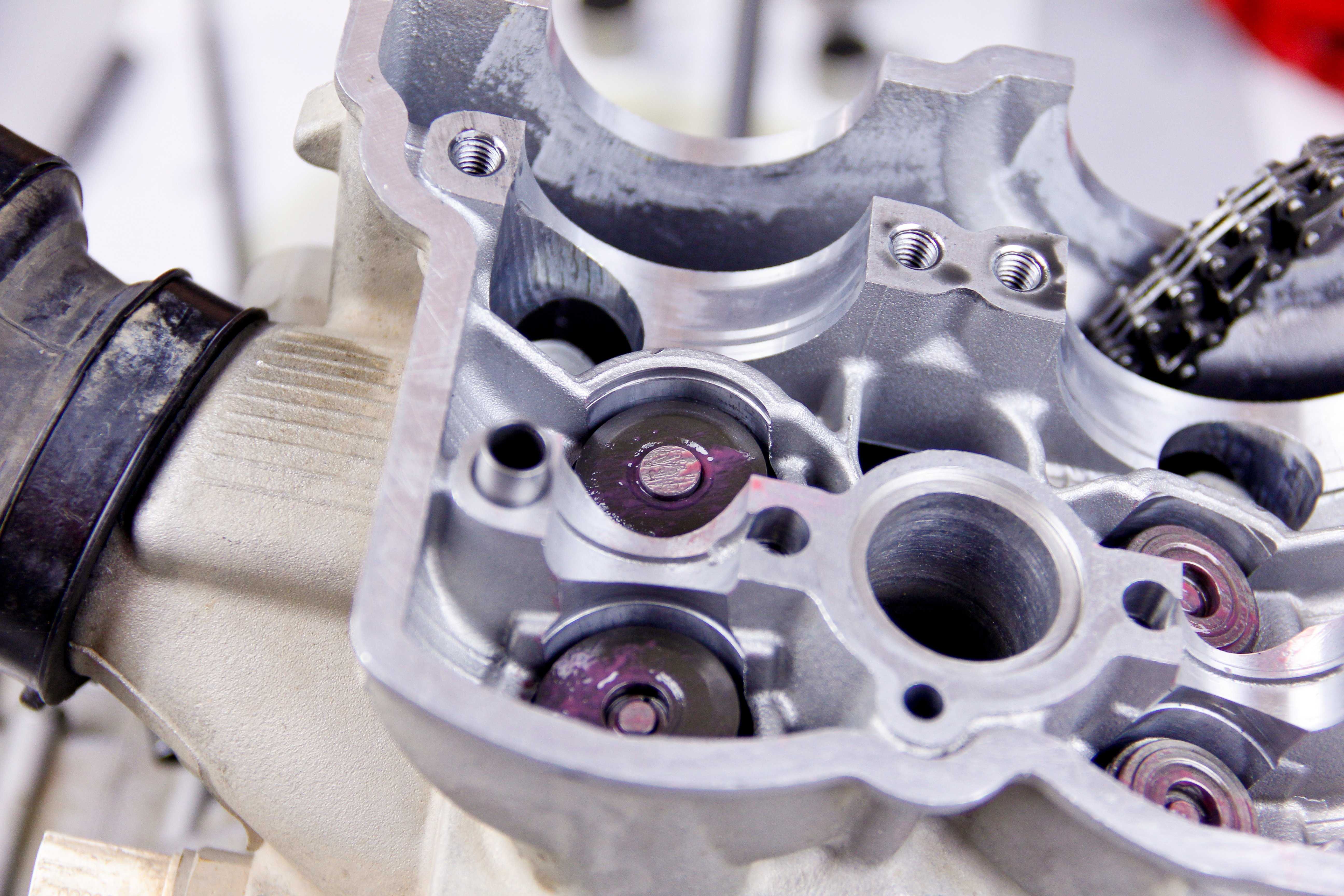

Measuring Valve Clearance

Measuring valve clearance is a relatively straightforward process, requiring specialized tools and a bit of patience.

- Tools: You’ll need a feeler gauge set, a torque wrench, and a suitable wrench for the valve cover bolts.

- Procedure:

- Remove the valve cover and locate the rocker arms.

- Turn the engine to the correct position for the valve you’re measuring. This ensures the valve is fully closed.

- Insert the feeler gauge between the valve stem and the rocker arm.

- The feeler gauge should slide in with a slight resistance.

- Repeat this process for each valve.

- If the clearance is outside the specified range, adjust the valve using shims or other methods, depending on the engine design.

V-Strom Valve Clearance Adjustment Procedure

Valve clearance adjustment is a crucial maintenance task for your V-Strom motorcycle, ensuring optimal engine performance and longevity. This procedure involves checking and adjusting the clearance between the valve stems and camshafts.

Tools and Materials Required

Before you begin, gather the necessary tools and materials to ensure a smooth and efficient adjustment process.

- Service manual for your specific V-Strom model

- Valve clearance gauges (feelers)

- Torque wrench

- Socket set

- Ratchet wrench

- Pliers

- Clean rags

- Optional: Magnetic pick-up tool

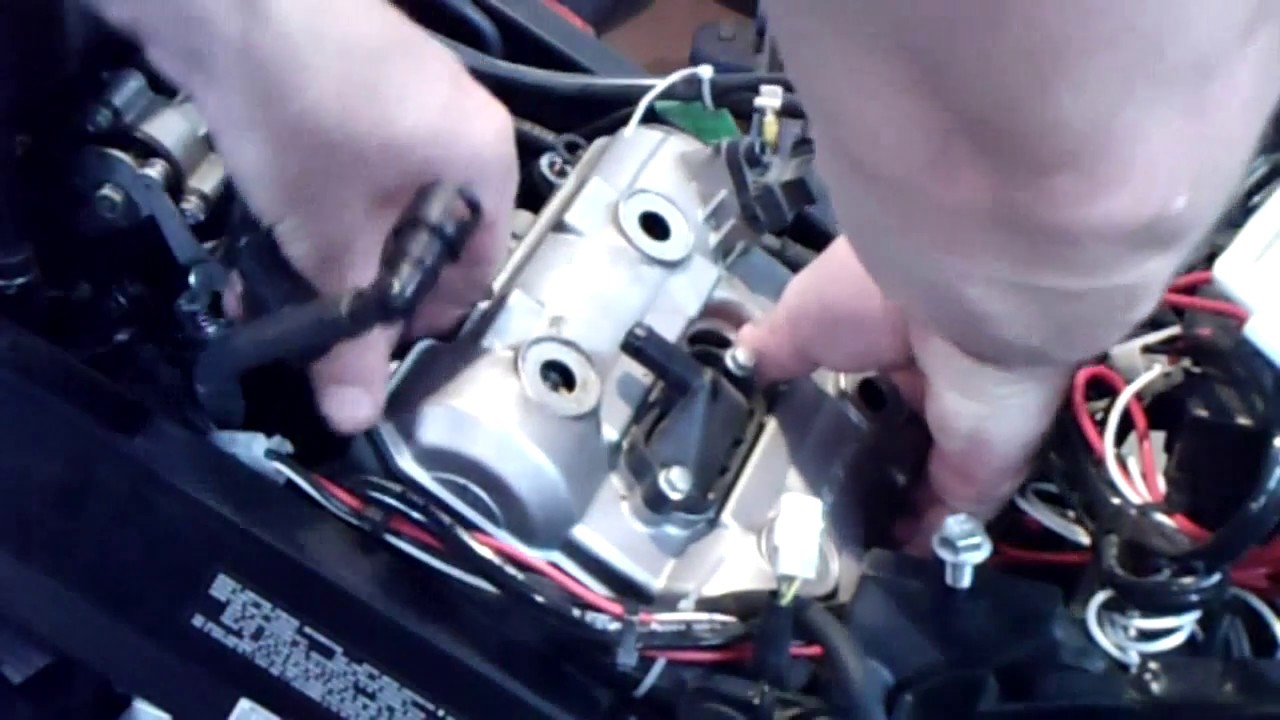

Step-by-Step Guide

The valve clearance adjustment process is straightforward but requires careful attention to detail.

- Warm up the engine: Start the engine and let it run for a few minutes to reach operating temperature. This ensures accurate valve clearance measurements.

- Remove the spark plugs: Disconnect the spark plug wires and remove the spark plugs to prevent accidental ignition during the adjustment process.

- Locate the valve adjusters: Consult your service manual for the location of the valve adjusters on your V-Strom model. They are typically found on the camshaft cover.

- Check the valve clearance: Using the appropriate feeler gauge, insert it between the valve stem and the camshaft lobe. The clearance should match the specifications provided in your service manual.

- Adjust the valve clearance: If the clearance is out of spec, use the valve adjuster to increase or decrease the clearance. The adjuster may be a screw or a locknut.

- Screw-type adjuster: Loosen the locknut and turn the adjuster screw to increase or decrease the clearance. Tighten the locknut after adjusting.

- Locknut-type adjuster: Loosen the locknut and turn the adjuster screw to increase or decrease the clearance. Tighten the locknut after adjusting.

- Re-check the valve clearance: After adjusting the clearance, re-check it with the feeler gauge to ensure it is within the specified range.

- Repeat for all valves: Repeat the above steps for each valve on the engine.

- Tighten the valve adjusters: Once all valves are adjusted, tighten the valve adjusters to the specified torque specifications provided in your service manual. Use a torque wrench to ensure proper tightening.

- Reinstall the spark plugs: Install the spark plugs and connect the spark plug wires.

- Start the engine: Start the engine and check for any unusual noises or vibrations. If everything is normal, you have successfully adjusted the valve clearance.

Torque Specifications

Torque specifications for valve adjusters vary depending on the V-Strom model. Always refer to your service manual for the correct torque values for your specific model.

Example: For a 2020 V-Strom 1050XT, the valve adjuster torque specification is typically around 10-12 Nm.

V-Strom Valve Clearance Intervals

Valve clearance adjustment intervals are crucial for maintaining optimal engine performance and longevity in your V-Strom motorcycle. Regularly checking and adjusting valve clearances ensures proper combustion and prevents premature wear on critical engine components.

Valve Clearance Adjustment Intervals for V-Strom Models

Valve clearance adjustment intervals vary depending on the specific V-Strom model and its engine type. Generally, Suzuki recommends checking and adjusting valve clearances at specific mileage intervals. Here’s a breakdown of typical intervals for different V-Strom models:

- V-Strom 650 (2004-2012): Every 12,000 miles (19,312 km)

- V-Strom 650 (2013-Present): Every 16,000 miles (25,750 km)

- V-Strom 1000 (2002-2013): Every 12,000 miles (19,312 km)

- V-Strom 1000 (2014-Present): Every 16,000 miles (25,750 km)

Factors Influencing Valve Clearance Adjustment Frequency

Several factors can influence the frequency of valve clearance adjustments. These factors can accelerate wear on valve components and necessitate more frequent checks.

- Riding Conditions: Aggressive riding, frequent high-RPM use, and extended periods of high engine load can accelerate valve wear.

- Engine Modifications: Performance modifications like aftermarket exhaust systems or high-compression pistons can affect valve clearance.

- Engine Oil Quality: Using the wrong type of engine oil or neglecting regular oil changes can lead to increased wear on valve components.

- Environmental Factors: Extreme temperatures and dusty environments can accelerate valve wear.

V-Strom Valve Clearance Specifications

The following table summarizes the valve clearance specifications for various V-Strom engines:

| Engine Model | Intake Clearance (mm) | Exhaust Clearance (mm) |

|---|---|---|

| V-Strom 650 (2004-Present) | 0.10-0.15 | 0.15-0.20 |

| V-Strom 1000 (2002-Present) | 0.10-0.15 | 0.15-0.20 |

Note: It’s essential to consult your V-Strom’s owner’s manual for the specific valve clearance specifications for your model year.

Troubleshooting Valve Clearance Issues: Do You Ever Adjust Valve Clearance On V Strom

Valve clearance problems can lead to a variety of issues on your V-Strom, from poor performance to engine damage. Understanding the common symptoms, potential causes, and troubleshooting techniques can help you diagnose and resolve these issues efficiently.

Common Symptoms of Incorrect Valve Clearance

Incorrect valve clearance can manifest in various ways. It’s important to be aware of these symptoms to catch problems early.

- Rough Idle: A rough or uneven idle is a common sign of incorrect valve clearance. Valves that are too tight can restrict airflow, causing the engine to run poorly at idle. Conversely, valves that are too loose can lead to a noisy idle and potential valve damage.

- Loss of Power: If your V-Strom experiences a noticeable loss of power, especially at higher RPMs, it could indicate a valve clearance issue. Tight valves can restrict airflow, limiting the engine’s power output.

- Increased Fuel Consumption: Incorrect valve clearance can disrupt the engine’s combustion process, leading to inefficient fuel burning and increased fuel consumption.

- Unusual Engine Noises: A tapping or clicking sound coming from the engine, particularly at high RPMs, could be a sign of valve clearance problems. This noise might indicate valves that are too loose, causing them to strike the piston or other engine components.

- Backfiring: Backfiring, especially during deceleration, can be caused by incorrect valve clearance. Tight valves can impede exhaust flow, leading to unburnt fuel igniting in the exhaust system.

Potential Causes of Valve Clearance Problems

Valve clearance problems can arise from various factors.

- Worn Valve Components: Over time, the valve stems, valve seats, or valve guides can wear down. This wear can cause the valve to sit at an incorrect height, leading to incorrect clearance.

- Improper Adjustment: Incorrectly adjusting the valve clearance during maintenance is a common cause of problems. This can happen due to improper measuring, incorrect shims being used, or a lack of experience in performing the adjustment procedure.

- Engine Wear: General wear and tear on the engine can affect valve clearance. This can include wear on the camshaft lobes, which can alter the timing and affect the valve lift.

- Heat Cycling: Repeated heating and cooling cycles of the engine can cause the valve components to expand and contract, potentially affecting valve clearance over time.

Troubleshooting Valve Clearance Issues

Diagnosing and resolving valve clearance issues requires a systematic approach.

- Visual Inspection: Start by visually inspecting the valve train components for any signs of wear or damage. Look for signs of scoring on the valve stems, valve seats, or valve guides.

- Compression Test: Perform a compression test to assess the engine’s overall health and identify any potential cylinder issues. Low compression can indicate a problem with the valves or other engine components.

- Measure Valve Clearance: Use a feeler gauge to measure the valve clearance at each valve. Compare the measurements to the factory specifications. If the clearance is out of spec, you’ll need to adjust it.

- Identify the Source of the Problem: Once you’ve identified that valve clearance is the issue, determine the underlying cause. Is it worn valve components, improper adjustment, or a combination of factors?

- Address the Root Cause: Based on your diagnosis, take appropriate action. This might involve replacing worn components, adjusting the valve clearance, or addressing other engine-related issues.

Expert Advice on Valve Clearance

Valve clearance is a crucial aspect of your V-Strom’s engine performance and longevity. Neglecting regular checks and adjustments can lead to serious issues, including reduced power, engine damage, and even catastrophic failure.

Importance of Regular Valve Clearance Checks

Regular valve clearance checks are essential for maintaining optimal engine performance and preventing potential damage.

“Think of valve clearance as the gap between a hammer and a nail,” explains John, a seasoned motorcycle mechanic with over 20 years of experience. “If the gap is too small, the valve won’t open fully, restricting airflow and reducing power. If the gap is too large, the valve can rattle and eventually damage the valve seat or even break.”

John emphasizes that valve clearance changes over time due to wear and tear on the valve train components. This is why regular checks are critical, even if your V-Strom is relatively new.

Benefits of Professional Valve Clearance Adjustment

Having a professional adjust your V-Strom’s valve clearance offers several benefits:

- Accurate Adjustment: Experienced mechanics use specialized tools and gauges to ensure precise valve clearance settings, ensuring optimal engine performance and longevity.

- Proper Torque: Mechanics apply the correct torque to the valve adjusting nuts, preventing damage to the valve train components.

- Early Detection: During a valve clearance check, a mechanic can identify other potential issues with the valve train, such as worn camshafts or rocker arms, allowing for timely repairs.

Finding a Reputable Motorcycle Mechanic, Do you ever adjust valve clearance on v strom

When searching for a reputable motorcycle mechanic for valve clearance adjustments, consider the following:

- Experience: Look for a mechanic with experience working on V-Stroms or similar motorcycles. They will be familiar with the specific valve clearance specifications and adjustment procedures for your bike.

- Reputation: Ask for recommendations from fellow riders or check online reviews. A good mechanic will have a solid reputation for quality work and customer satisfaction.

- Certifications: Look for mechanics with certifications from reputable organizations, such as the Motorcycle Mechanics Institute (MMI) or the National Automotive Technicians Education Foundation (NATEF). These certifications indicate that the mechanic has met specific training and competency standards.

Maintaining the correct valve clearance on your V-Strom is vital for optimal engine performance and longevity. By understanding the basics, following the adjustment procedure, and performing regular checks, you can ensure your motorcycle runs smoothly and efficiently. Remember, regular maintenance is key to preventing costly repairs and enjoying trouble-free riding. If you’re unsure about adjusting valve clearance yourself, consulting a reputable motorcycle mechanic is always recommended.

Question Bank

How often should I adjust valve clearance on my V-Strom?

The recommended valve clearance adjustment intervals vary depending on the V-Strom model. Consult your owner’s manual for specific recommendations. Generally, it’s advisable to check valve clearance every 12,000 to 15,000 miles or annually.

What happens if I don’t adjust valve clearance on my V-Strom?

Neglecting valve clearance adjustments can lead to various issues, including decreased engine performance, reduced fuel efficiency, excessive noise, and even engine damage. It’s essential to maintain proper valve clearance for optimal engine health.

Can I adjust valve clearance myself?

While it’s possible to adjust valve clearance yourself, it’s a complex procedure that requires specialized tools and technical knowledge. If you’re not comfortable performing the adjustment, it’s best to seek professional help from a qualified motorcycle mechanic.

What are the symptoms of incorrect valve clearance on a V-Strom?

Symptoms of incorrect valve clearance can include rough idling, loss of power, backfiring, excessive noise, and unusual engine vibrations. If you notice any of these symptoms, it’s advisable to have your valve clearance checked by a mechanic.