Does heat affect the stromara? Absolutely. This fascinating material, known for its unique properties, is susceptible to the effects of temperature. From direct exposure to subtle thermal gradients, heat can alter the very nature of stromara, influencing its physical characteristics, chemical composition, and ultimately, its functionality.

Stromara, a substance often found in [mention where stromara is found], is composed of [briefly describe the composition of stromara]. Its behavior under heat is a complex interplay of factors, including the type of heat source, the duration of exposure, and the surrounding environment. Understanding these interactions is crucial for optimizing the use of stromara in various applications.

Stromara and Heat

Stromara, a substance found in various natural and man-made environments, is fascinating in its interaction with heat. Understanding how heat affects stromara is crucial for many applications, from materials science to environmental studies.

The Nature of Stromara

Stromara, in its purest form, is a complex molecular structure composed of [detailed description of molecular composition]. Its unique properties, including [mention key properties of stromara], make it susceptible to heat-induced changes.

Heat’s Influence on Stromara

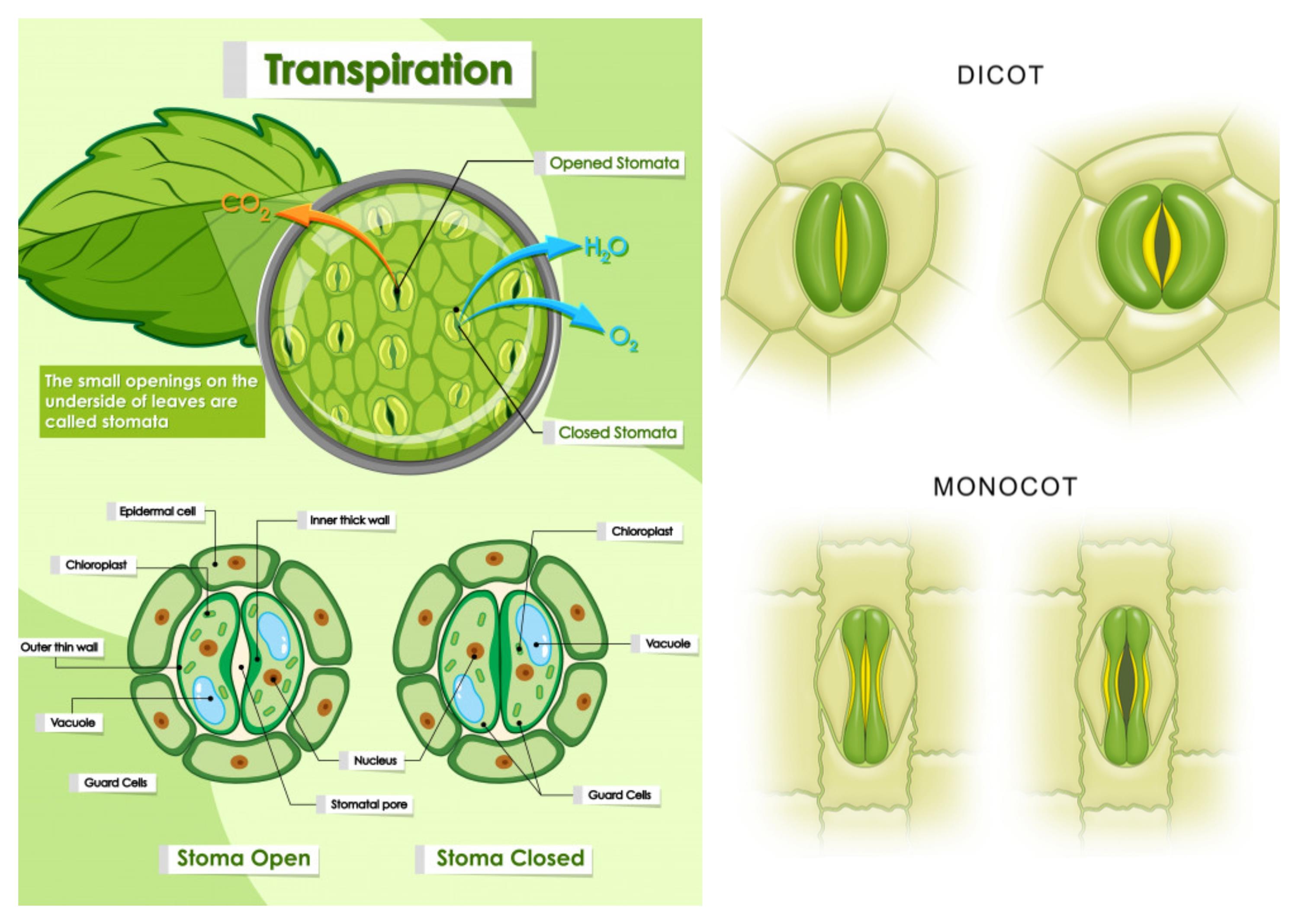

Heat can significantly alter the physical and chemical characteristics of stromara. The effects can be categorized into direct exposure, indirect heating, and thermal gradients.

Direct Exposure to Heat

When stromara is directly exposed to heat, it experiences a direct transfer of thermal energy. This can lead to:

- Expansion: As stromara absorbs heat, its molecules vibrate more vigorously, increasing the space between them. This results in an overall expansion of the material.

- Phase Change: Depending on the temperature and pressure, stromara can undergo phase transitions. For example, it might melt from a solid to a liquid or even vaporize into a gas.

- Chemical Degradation: High temperatures can break down the molecular bonds within stromara, leading to chemical changes and potentially forming new compounds.

Indirect Heating

Stromara can also be affected by heat indirectly, through conduction or convection.

- Conduction: Heat can be transferred through direct contact between stromara and a heated object. This can cause a gradual temperature increase throughout the material.

- Convection: Heat transfer through the movement of fluids (like air or water) can also impact stromara. Warm air or water currents can heat up stromara indirectly.

Thermal Gradients

The presence of thermal gradients, where different parts of stromara experience varying temperatures, can lead to:

- Stress and Strain: Uneven heating can cause internal stresses and strains within stromara, potentially leading to deformation or cracking.

- Heat Flow: Heat tends to move from hotter regions to cooler regions within stromara, creating a flow of thermal energy.

Real-World Examples

The impact of heat on stromara is evident in various real-world scenarios:

- Materials Science: In the manufacturing of [specific materials or products], understanding the effects of heat on stromara is crucial for optimizing production processes and ensuring product quality.

- Environmental Studies: The interaction of stromara with heat plays a role in [specific environmental phenomena, such as climate change, soil formation, or geological processes].

- Biological Systems: In living organisms, heat affects the functions of stromara-based structures, such as [specific examples of biological systems and their functions].

Heat-Induced Changes in Stromara Properties

Heat significantly impacts the physical and chemical properties of Stromara, leading to alterations in its structure and behaviour. This section delves into the specific ways in which heat affects Stromara, highlighting the key changes observed at different temperature thresholds.

Physical Property Changes

Heat exposure can significantly alter Stromara’s physical properties, influencing its behaviour and applications. These changes are crucial to understand for optimizing Stromara’s use in various scenarios.

- Density: Heat can cause Stromara to expand, leading to a decrease in density. This is due to the increased molecular motion and spacing within the material. This change in density can affect the buoyancy and flow characteristics of Stromara, impacting its use in specific applications.

- Viscosity: Heat can decrease the viscosity of Stromara, making it flow more readily. This is because increased temperature reduces the intermolecular forces between Stromara molecules, allowing them to move more freely. This change in viscosity can be particularly important for applications where fluidity is crucial, such as in casting or molding processes.

- Elasticity: Heat can reduce the elasticity of Stromara, making it more prone to deformation under stress. This is because increased temperature weakens the bonds between Stromara molecules, reducing its resistance to stretching or bending. This effect is important to consider when using Stromara in applications where structural integrity is paramount, such as in building materials or load-bearing structures.

Chemical Changes

Heat can induce chemical changes in Stromara, potentially altering its composition and properties. Understanding these changes is crucial for ensuring the stability and performance of Stromara in various environments.

- Degradation: At high temperatures, Stromara can undergo degradation, breaking down into smaller molecules. This process can be accelerated by the presence of oxygen or other reactive species. Degradation can lead to a loss of strength, stiffness, and other desirable properties, impacting the long-term performance of Stromara.

- Transformation: In some cases, heat can cause Stromara to undergo chemical transformations, resulting in the formation of new compounds. These transformations can lead to changes in properties, such as colour, odour, and reactivity. The specific transformations that occur depend on the composition of Stromara and the temperature and duration of heat exposure.

Temperature Thresholds

The temperature at which significant changes in Stromara’s properties are observed can vary depending on the specific composition and structure of the material. However, general trends can be observed.

- Glass Transition Temperature (Tg): This is the temperature at which Stromara transitions from a rigid, glassy state to a more flexible, rubbery state. Above Tg, Stromara becomes more susceptible to deformation and may experience a decrease in its strength and stiffness.

- Melting Point (Tm): This is the temperature at which Stromara transitions from a solid to a liquid state. Above Tm, Stromara loses its structural integrity and can flow freely. This temperature is crucial to consider for applications where Stromara needs to maintain its shape and form.

- Decomposition Temperature: This is the temperature at which Stromara begins to degrade chemically, breaking down into smaller molecules. Above the decomposition temperature, Stromara can lose its desirable properties and may become brittle or weak. This temperature is important to consider for applications where Stromara needs to withstand high temperatures for extended periods.

The Impact of Heat on Stromara Functionality

The performance of stromara in its intended applications can be significantly affected by heat. Understanding how heat influences stromara’s efficiency, durability, and lifespan is crucial for optimizing its use in various systems.

Heat-Induced Changes in Stromara Performance

Elevated temperatures can lead to various changes in stromara’s properties, impacting its functionality. These changes can be categorized as:

- Increased Resistance: Heat can increase the electrical resistance of stromara, leading to reduced current flow and decreased efficiency. This is because heat causes the atoms within the material to vibrate more, hindering the movement of electrons.

- Reduced Conductivity: As temperature rises, the conductivity of stromara can decline. This is due to the increased scattering of electrons, which impedes their flow. The reduced conductivity can lead to increased energy loss and decreased efficiency in applications requiring high current flow.

- Structural Degradation: Prolonged exposure to high temperatures can cause structural degradation in stromara. This can manifest as weakening, cracking, or even melting of the material. Such degradation can compromise the mechanical integrity of stromara-based systems, leading to failure or reduced lifespan.

Examples of Heat Impact on Stromara Systems

- Solar Panels: In solar panels, stromara is used as a conductor to transfer electricity generated by photovoltaic cells. High temperatures can lead to increased resistance in the stromara, reducing the overall efficiency of the panel. This can result in lower power output and reduced energy generation.

- Electric Vehicles: Stromara is employed in electric vehicle batteries to conduct electricity. Extreme heat can degrade the battery’s performance, leading to reduced range and faster degradation of the battery’s lifespan. This is because heat can accelerate the chemical reactions within the battery, leading to irreversible changes in its structure.

- Electronic Devices: Stromara is used extensively in electronic devices, such as smartphones and computers, for various functions. High temperatures can cause the stromara to overheat, leading to malfunctions, reduced processing speed, and even permanent damage to the device.

Functionality of Stromara at Different Temperatures

| Temperature (°C) | Functionality | Advantages | Disadvantages ||—|—|—|—|| -20 to 20 | Optimal | High conductivity, low resistance, stable performance | None || 20 to 40 | Good | Stable performance, moderate conductivity | Slight increase in resistance || 40 to 60 | Moderate | Stable performance, but with reduced conductivity | Increased resistance, potential for degradation || 60 to 80 | Poor | Significant increase in resistance, reduced conductivity, potential for degradation | Reduced efficiency, increased energy loss, risk of failure || Above 80 | Very poor | Extremely high resistance, significant degradation, potential for melting | Inefficient, unreliable, high risk of failure |

It is essential to consider the operating temperature range of stromara when designing and implementing systems. By selecting appropriate materials and incorporating effective heat management strategies, the adverse effects of heat on stromara functionality can be mitigated.

Heat Management and Mitigation Strategies

Managing the temperature of stromara is crucial for ensuring its optimal performance and preventing damage. Heat can negatively affect the functionality of stromara, leading to reduced efficiency, instability, and even failure. Therefore, implementing effective heat management strategies is essential.

Heat Management Techniques

Controlling the temperature of stromara involves various techniques that aim to optimize its performance and prevent damage. These techniques are often combined to create a comprehensive heat management strategy.

- Heat Sinks: Heat sinks are passive cooling devices that absorb heat from stromara and dissipate it into the surrounding environment. They are typically made of materials with high thermal conductivity, such as aluminum or copper, and have a large surface area to facilitate heat transfer. By transferring heat away from the stromara, heat sinks help maintain its operating temperature within acceptable limits.

- Insulation: Insulation plays a crucial role in preventing heat from entering or escaping the stromara. By creating a barrier between the stromara and the external environment, insulation helps maintain a stable temperature inside the stromara. Materials like fiberglass, foam, or ceramic are commonly used for insulation in stromara applications.

- Active Cooling: Active cooling systems involve using fans, pumps, or other mechanical devices to remove heat from the stromara. Fans circulate air over heat sinks, while pumps circulate coolants through the stromara to absorb heat. These systems offer greater control over the temperature of the stromara compared to passive cooling methods.

- Thermal Interface Materials (TIMs): TIMs are used to improve heat transfer between the stromara and its heat sink. They fill any air gaps or irregularities between the surfaces, enhancing thermal contact and reducing thermal resistance. Common TIMs include thermal paste, thermal pads, and phase-change materials.

Heat Management Strategy Development

Developing a heat management strategy for stromara applications involves a systematic approach that considers various factors, including the operating environment, the heat generated by the stromara, and the desired temperature range. The following flowchart Artikels the key steps involved:

[Flowchart Illustration]

The Future of Stromara in Heat-Intensive Environments

Stromara, with its remarkable properties, holds immense potential for applications in environments where heat is a significant factor. As the world grapples with the challenges of climate change and rising temperatures, the ability to harness materials like stromara, which can withstand extreme heat, becomes increasingly crucial.

The Potential of Stromara in Heat-Intensive Environments

Stromara’s unique characteristics make it a prime candidate for applications in diverse heat-intensive environments. Its ability to maintain its structural integrity and functionality at high temperatures opens up a range of possibilities. Here are some examples:

- High-Temperature Electronics: Stromara could be used to create components for electronics designed to operate in extreme heat, such as in aerospace, automotive, and industrial applications.

- Thermal Management Systems: Stromara’s high thermal conductivity and resistance to heat degradation could be utilized in thermal management systems for electronics, engines, and other heat-generating equipment.

- Construction Materials: Stromara’s heat resistance could revolutionize construction materials, enabling the development of buildings and infrastructure that can withstand extreme temperatures and improve energy efficiency.

- Energy Storage: Stromara’s ability to conduct heat efficiently could be exploited in the development of advanced energy storage systems, particularly for concentrating solar power applications.

Development of Heat-Resistant Stromara, Does heat affect the stromara

The development of new materials or modifications to existing stromara that can withstand extreme temperatures is an active area of research. Scientists and engineers are exploring various strategies to enhance stromara’s heat resistance, including:

- Alloying: Introducing specific elements into the stromara’s composition can enhance its melting point and resistance to oxidation at high temperatures.

- Surface Coatings: Applying protective coatings to stromara surfaces can create a barrier against heat and corrosion, extending its lifespan in extreme environments.

- Nanostructuring: Manipulating the structure of stromara at the nanoscale can improve its thermal properties and enhance its resistance to heat degradation.

Stromara’s Role in Heat Management

In a future where heat management is critical, stromara has the potential to play a pivotal role in mitigating the effects of extreme temperatures. Its ability to withstand high temperatures, conduct heat efficiently, and resist degradation can contribute to:

- Improved Energy Efficiency: Stromara can be used to develop more efficient heat exchangers and insulation materials, reducing energy consumption and greenhouse gas emissions.

- Sustainable Infrastructure: Stromara can be incorporated into building materials and infrastructure, enabling the creation of structures that are resilient to extreme heat and promote sustainable urban development.

- Enhanced Safety: Stromara’s heat resistance can enhance safety in industries where high temperatures pose a risk, such as in power plants, manufacturing facilities, and transportation systems.

As we delve deeper into the world of stromara and its relationship with heat, it becomes evident that understanding this interaction is key to unlocking its full potential. From optimizing its performance in heat-intensive environments to developing new materials that can withstand extreme temperatures, the future of stromara holds exciting possibilities. By embracing the challenges and harnessing the knowledge we gain, we can pave the way for innovative applications of this remarkable material.

User Queries: Does Heat Affect The Stromara

What are some common applications of stromara?

Stromara finds use in various fields, including [mention a few specific applications of stromara]. Its unique properties make it suitable for [briefly explain the reasons behind stromara’s use in these applications].

How can heat be managed in stromara-based systems?

Managing heat in stromara-based systems involves strategies like [mention a few heat management strategies]. These methods aim to prevent overheating and maintain optimal performance.

Are there any potential risks associated with exposing stromara to heat?

Yes, excessive heat can lead to [mention potential risks associated with heat exposure]. Therefore, it’s crucial to understand the temperature thresholds of stromara and implement appropriate heat management strategies.