How to secure a trailer hitch is a super important thing to know, especially if you’re planning on hauling your stuff around town or on a road trip. It’s like, the foundation of safe towing, and you don’t want to mess it up. Think of it like this: you wouldn’t go skydiving without a parachute, right? Same thing with towing.

You gotta make sure your trailer hitch is set up right, so you don’t end up with a disaster on your hands.

This guide is gonna walk you through everything you need to know, from choosing the right hitch to making sure it’s installed correctly. We’ll also cover some safety tips and tricks that’ll help you tow like a pro. So, buckle up and get ready to learn!

Choosing the Right Trailer Hitch

A trailer hitch is a crucial component of your towing setup, ensuring safe and secure connection between your vehicle and trailer. Choosing the right hitch is essential for optimal performance and safety. It involves considering the trailer’s weight, your vehicle’s towing capacity, and the type of hitch best suited for your needs.

Understanding Trailer Hitch Classes

Trailer hitches are categorized into different classes based on their weight capacities, providing a standardized system for selecting the appropriate hitch for your towing needs. Each class has a specific weight rating, indicating the maximum weight it can safely handle.

- Class I: Designed for light-duty towing, typically used for small trailers like cargo carriers, bike racks, or utility trailers with a gross trailer weight (GTW) of up to 2,000 pounds. These hitches are usually installed on smaller vehicles like compact cars or SUVs.

- Class II: Suitable for medium-duty towing, handling trailers with a GTW of up to 3,500 pounds. This class is often found on mid-size SUVs, pickup trucks, and some vans.

- Class III: Commonly used for heavier trailers, including travel trailers, boat trailers, and small campers, with a GTW of up to 6,000 pounds. Class III hitches are typically found on full-size SUVs, pickup trucks, and some vans.

- Class IV: Designed for heavy-duty towing, handling trailers with a GTW of up to 10,000 pounds. These hitches are usually found on heavy-duty pickup trucks and are often used for towing large trailers, such as horse trailers, fifth-wheel campers, and large utility trailers.

- Class V: The highest weight capacity class, handling trailers with a GTW of up to 17,000 pounds. These hitches are typically found on heavy-duty pickup trucks and are used for towing extremely heavy trailers, such as large commercial trailers or specialized equipment trailers.

Factors to Consider When Choosing a Trailer Hitch

- Trailer Weight: The most crucial factor is the trailer’s weight. Determine the gross trailer weight (GTW), which includes the trailer’s weight, cargo, and passengers. Choose a hitch with a weight capacity that exceeds the GTW.

- Vehicle Towing Capacity: Your vehicle’s towing capacity, found in the owner’s manual or on a sticker on the driver’s side doorjamb, indicates the maximum weight it can safely tow. Ensure the trailer’s weight does not exceed your vehicle’s towing capacity.

- Hitch Type: There are various hitch types, including receiver hitches, gooseneck hitches, and fifth-wheel hitches. Receiver hitches are the most common type, with varying weight capacities based on the class. Gooseneck and fifth-wheel hitches are designed for heavier trailers and offer increased stability and weight distribution.

Comparing Different Hitch Types

| Hitch Type | Weight Rating | Typical Applications |

|---|---|---|

| Class I | Up to 2,000 lbs | Small trailers, cargo carriers, bike racks, utility trailers |

| Class II | Up to 3,500 lbs | Medium-duty trailers, small campers, boat trailers |

| Class III | Up to 6,000 lbs | Travel trailers, boat trailers, small campers, utility trailers |

| Class IV | Up to 10,000 lbs | Large trailers, horse trailers, fifth-wheel campers, large utility trailers |

| Class V | Up to 17,000 lbs | Extremely heavy trailers, large commercial trailers, specialized equipment trailers |

Installation Process

Installing a trailer hitch is a relatively straightforward process, but it requires some mechanical skills and attention to detail. The right tools and equipment, combined with careful adherence to the manufacturer’s instructions, are crucial for a safe and secure installation.

Necessary Tools and Equipment

Before embarking on the installation process, ensure you have all the necessary tools and equipment readily available. These include:

- Jack and Jack Stands: To safely lift the vehicle and provide stability during installation.

- Wrench Set: For loosening and tightening bolts and nuts.

- Socket Set: To access and tighten bolts in hard-to-reach areas.

- Torque Wrench: To ensure bolts are tightened to the manufacturer’s specifications.

- Drill and Drill Bits: For drilling pilot holes if required.

- Safety Glasses: To protect your eyes from debris.

- Work Gloves: To protect your hands.

- Level: To ensure the hitch is installed level.

- Marker: To mark bolt holes and other reference points.

Steps for Installing a Trailer Hitch

The installation process for a trailer hitch varies slightly depending on the specific make and model of your vehicle and the type of hitch you’re installing. However, the general steps are as follows:

- Prepare the Vehicle: Park the vehicle on a level surface and engage the parking brake. Consult your vehicle’s owner’s manual for specific instructions on how to safely raise the vehicle using a jack and jack stands.

- Locate the Mounting Points: Refer to the hitch manufacturer’s instructions to identify the exact mounting points on your vehicle’s frame. Use a marker to clearly mark these locations.

- Position the Hitch: Carefully position the hitch over the marked mounting points. Ensure the hitch is level and aligned correctly before proceeding.

- Secure the Hitch: Use the provided hardware to secure the hitch to the vehicle’s frame. Tighten the bolts and nuts to the manufacturer’s specified torque settings. This step may require a torque wrench to ensure proper tightening.

- Test the Installation: After securing the hitch, perform a thorough inspection to ensure all bolts and nuts are securely fastened. Gently rock the hitch to check for any looseness or instability.

- Lower the Vehicle: Carefully lower the vehicle using the jack and jack stands. Double-check that the hitch is securely installed and that all components are properly aligned.

Always refer to the hitch manufacturer’s instructions for specific installation details and safety precautions.

Hitch Ball and Accessories

The hitch ball is the critical component that connects your trailer to your vehicle’s hitch receiver. It is essential to choose the right size and type of hitch ball to ensure a secure and safe connection. This section will discuss the various hitch ball sizes and types, as well as important accessories like hitch locks, safety chains, and wiring harnesses.

Hitch Ball Sizes

The size of a hitch ball is measured in inches, and the most common sizes are 1 7/8 inches, 2 inches, and 2 5/16 inches. The correct size hitch ball must match the size of the trailer coupler. The trailer coupler is the part of the trailer that connects to the hitch ball.

- 1 7/8-inch hitch balls are the most common size and are suitable for most light-duty trailers, such as utility trailers, boat trailers, and small campers.

- 2-inch hitch balls are used for heavier trailers, such as larger campers, travel trailers, and some cargo trailers.

- 2 5/16-inch hitch balls are the largest size and are used for extremely heavy trailers, such as large commercial trailers.

It is crucial to use the correct size hitch ball for the trailer coupler. Using a hitch ball that is too small can lead to the trailer disconnecting from the vehicle, while using a hitch ball that is too large can damage the trailer coupler.

Hitch Ball Types, How to secure a trailer hitch

There are two main types of hitch balls: standard hitch balls and pintle hitch balls.

- Standard hitch balls are the most common type and have a round shape. They are designed to fit into a standard trailer coupler.

- Pintle hitch balls have a square or rectangular shape and are designed to fit into a pintle hook trailer coupler. Pintle hitch balls are typically used for heavy-duty trailers, such as commercial trailers.

Hitch Ball Accessories

In addition to the hitch ball itself, there are several accessories that can enhance safety and security when towing a trailer.

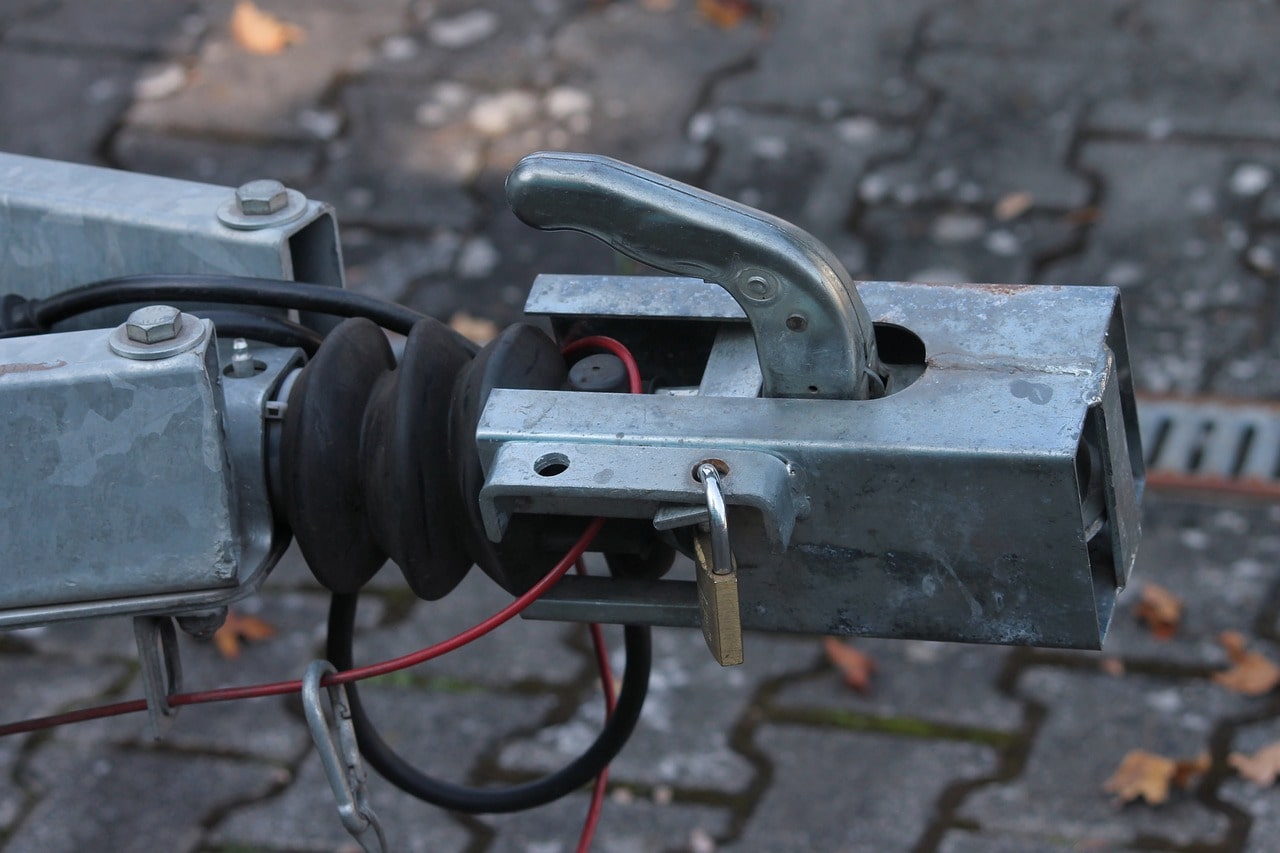

Hitch Locks

Hitch locks are devices that are designed to prevent the trailer from being disconnected from the vehicle. They are typically made of metal and are designed to fit over the hitch ball. Hitch locks can be a valuable deterrent against theft, especially in areas where trailers are frequently stolen.

Safety Chains

Safety chains are two chains that are attached to the trailer frame and run to the hitch receiver on the vehicle. They are designed to prevent the trailer from disconnecting from the vehicle in the event of a hitch ball failure. Safety chains should always be crossed and connected to the hitch receiver in a way that prevents them from becoming entangled.

Wiring Harnesses

A wiring harness is a set of wires that connects the trailer lights to the vehicle’s taillights. It allows the trailer’s brake lights, turn signals, and running lights to function properly. Wiring harnesses come in different configurations depending on the type of trailer and the vehicle.

Safety and Maintenance

Ensuring the safety and longevity of your trailer hitch is paramount. Regular inspections and maintenance are crucial for identifying potential issues before they escalate into serious problems. This proactive approach can prevent accidents and ensure your towing adventures are safe and enjoyable.

Inspecting for Wear and Damage

Thorough inspections are essential to identify any signs of wear or damage on the hitch and its components. This includes visually checking for cracks, rust, or excessive wear on the hitch receiver, ball mount, hitch pin, and wiring.

- Hitch Receiver: Inspect the receiver for any cracks, dents, or excessive wear on the internal walls. The receiver should be free of rust and corrosion. If you notice any damage, it is crucial to replace the receiver immediately.

- Ball Mount: Carefully examine the ball mount for any cracks, dents, or signs of bending. The ball mount should be securely attached to the hitch receiver. If you detect any damage, it is essential to replace the ball mount.

- Hitch Pin: Check the hitch pin for any signs of wear, damage, or rust. The pin should be securely inserted into the hitch receiver and ball mount. Replace the pin if it shows signs of wear or damage.

- Wiring: Inspect the wiring harness for any signs of damage, frayed wires, or loose connections. Ensure all connections are secure and the lights on the trailer are functioning properly. If any issues are found, repair or replace the wiring as needed.

Maintenance Checklist

Regular maintenance is vital to ensure the safety and longevity of your trailer hitch. Here is a checklist of maintenance tasks to perform periodically:

- Clean and Lubricate: Regularly clean the hitch receiver, ball mount, and hitch pin with a wire brush and a mild detergent. Apply a light coat of lubricant to the moving parts to prevent rust and corrosion. This ensures smooth operation and prevents unnecessary wear.

- Tighten Connections: Check and tighten all connections, including the ball mount, hitch pin, and wiring harness, to ensure they are secure. Loose connections can lead to instability and accidents while towing.

- Inspect for Rust: Regularly inspect the hitch and its components for any signs of rust. Apply a rust-resistant coating to prevent further corrosion and extend the life of your hitch.

- Replace Worn Parts: Replace any worn or damaged parts immediately. This includes the hitch receiver, ball mount, hitch pin, and wiring harness. Using worn or damaged parts can compromise safety and lead to accidents.

“A well-maintained trailer hitch is a safe hitch.”

Towing Safely

Towing a trailer safely is crucial for both your well-being and the safety of others on the road. Understanding the principles of weight distribution, load balancing, and proper driving techniques is essential for a smooth and secure towing experience.

Weight Distribution and Load Balancing

Proper weight distribution and load balancing are paramount for safe and stable towing. An unevenly loaded trailer can lead to instability, making the vehicle difficult to control and increasing the risk of accidents.

- Tongue Weight: The tongue weight is the downward force exerted on the hitch ball by the trailer. It’s crucial to ensure the tongue weight falls within the manufacturer’s recommended range for your vehicle and trailer. A tongue weight that is too low can lead to trailer sway, while excessive tongue weight can overload the hitch and put stress on your vehicle’s suspension.

- Gross Vehicle Weight Rating (GVWR): This is the maximum weight your vehicle can safely handle, including the weight of the vehicle, passengers, cargo, and the trailer. Exceeding the GVWR can overload the vehicle’s brakes, suspension, and tires, leading to dangerous situations.

- Gross Trailer Weight Rating (GTWR): The GTWR is the maximum weight your trailer can safely carry. This includes the weight of the trailer itself, the cargo, and any accessories. Exceeding the GTWR can overload the trailer’s axles and tires, leading to structural damage and safety hazards.

Weight Distribution Hitches

Weight distribution hitches are designed to transfer some of the trailer’s weight from the hitch ball to the vehicle’s rear axle. This helps to improve stability and handling, especially when towing heavy trailers.

- Components: Weight distribution hitches typically consist of a hitch head, spring bars, and spring arms. The spring bars are connected to the hitch head and the spring arms, which are attached to the trailer frame.

- How it Works: As the trailer is loaded, the spring bars exert a downward force on the vehicle’s rear axle, transferring weight from the hitch ball to the rear axle. This helps to maintain a balanced weight distribution and improve stability.

- Benefits: Weight distribution hitches can improve handling, reduce trailer sway, and minimize stress on the vehicle’s suspension and tires. They are particularly beneficial when towing large or heavy trailers.

Sway Control Devices

Sway control devices are designed to help prevent trailer sway, which can occur when the trailer starts to move from side to side. Sway control systems use various mechanisms to stabilize the trailer and make towing safer.

- Friction-Based Sway Control: This type of sway control uses friction plates to absorb energy and dampen trailer movement. As the trailer starts to sway, the friction plates engage and resist the movement, helping to stabilize the trailer.

- Electronic Sway Control: Electronic sway control systems use sensors to detect trailer movement and activate brakes to counteract sway. They offer more precise and responsive control compared to friction-based systems.

Safe Driving and Maneuvering While Towing

Driving and maneuvering while towing a trailer requires extra caution and attention. Here are some essential tips to ensure a safe towing experience:

- Maintain a Safe Following Distance: Towing a trailer increases your vehicle’s stopping distance, so it’s crucial to maintain a greater following distance than usual. Allow for ample space between your vehicle and the car in front of you to ensure you have enough time to react in case of sudden braking.

- Be Mindful of Wind Conditions: High winds can create significant sway in a trailer. Be extra cautious when driving in windy conditions and reduce speed if necessary. Avoid driving alongside large trucks or other vehicles that may create strong gusts of wind.

- Avoid Sudden Braking and Acceleration: Sudden braking and acceleration can cause the trailer to sway or even jackknife. Be gentle with the brakes and accelerator, and avoid abrupt maneuvers. Anticipate traffic conditions and adjust your speed accordingly.

- Be Aware of Turning Radius: Towing a trailer significantly increases your vehicle’s turning radius. Make wider turns and be mindful of obstacles, particularly when making tight turns. Use your mirrors and backup camera to ensure you have ample clearance.

- Practice Safe Passing: When passing other vehicles, ensure you have ample space and visibility. Use your turn signals and check your mirrors frequently. Be mindful of the increased length of your vehicle and trailer when passing.

- Check Your Tires Regularly: Proper tire inflation is crucial for safe towing. Check your tires regularly, including the spare tire, and adjust the pressure as needed. Underinflated tires can overheat and lead to blowouts, while overinflated tires can reduce traction and handling.

So there you have it, a comprehensive guide to securing a trailer hitch. It’s a lot to take in, but it’s all super important for safe towing. Remember, you’re not just responsible for yourself, but for everyone on the road. By taking the time to learn how to secure your trailer hitch properly, you’re not only protecting yourself but also helping to keep others safe.

Now, go out there and tow with confidence, knowing that you’ve got the skills to handle any situation!

Common Queries: How To Secure A Trailer Hitch

What if I’m not sure what type of hitch I need?

No worries, dude! You can always check your vehicle’s owner’s manual or consult with a professional at an auto parts store. They’ll be able to help you figure out what’s best for your needs.

How often should I inspect my trailer hitch?

It’s a good idea to give it a once-over before every tow, just to make sure everything is tight and in good shape. And if you’re using it regularly, you should give it a more thorough inspection every few months.

Can I just use any old hitch ball?

Nope, you gotta use the right size hitch ball for your trailer coupler. Using the wrong size could cause damage to your hitch or your trailer, and that’s definitely not cool.