How do you stamp metal jewelry? This seemingly simple question opens a world of artistry and craftsmanship. From the delicate precision of hand stamping to the high-volume efficiency of machine stamping, the techniques involved are diverse and fascinating. This exploration delves into the various methods, tools, and skills necessary to create unique and personalized metal jewelry pieces, covering everything from metal preparation to finishing techniques.

We’ll examine the advantages and disadvantages of different approaches, ensuring you have the knowledge to choose the best method for your project.

The journey begins with understanding the different metal stamping techniques: hand stamping, ideal for intricate designs and small-scale production; machine stamping, perfect for mass production and consistent results; and power hammer stamping, suited for larger, more robust pieces. Each method requires specific tools and materials, and selecting the right ones is crucial for success. Proper metal preparation, including annealing and cleaning, is essential for achieving clean, crisp impressions.

We’ll then guide you through the stamping process itself, highlighting best practices and common pitfalls to avoid. Finally, we’ll explore various finishing techniques, from polishing to patination, to enhance the beauty and longevity of your creations.

Types of Metal Stamping for Jewelry

Metal stamping is a crucial technique in jewelry manufacturing, offering a versatile method for creating intricate designs and shapes. The choice of stamping method significantly impacts the final product’s quality, cost-effectiveness, and production scale. Several techniques exist, each with its own strengths and weaknesses.

Hand Stamping, How do you stamp metal jewelry

Hand stamping involves using a hammer and various stamps to imprint designs onto metal. This method allows for a high degree of artistic control and personalization, making it ideal for creating unique, one-of-a-kind pieces. The artisan can directly manipulate the process, adjusting force and angle for subtle variations in the stamped image. However, it’s a labor-intensive process, limiting production volume and increasing the overall cost per piece.

Softer metals, like copper, silver, and brass, are best suited for hand stamping due to their malleability. Overly hard metals risk damage to the stamps or uneven imprints.

Machine Stamping

Machine stamping utilizes specialized presses to rapidly stamp designs onto metal sheets. This automated process dramatically increases production speed and efficiency compared to hand stamping. Precision is also generally higher, leading to consistent results and reduced waste. However, the initial investment in machinery can be substantial, and the process is less adaptable to individual design variations. Machine stamping is well-suited for mass production runs of jewelry with consistent designs.

A wider range of metals can be used, though malleability remains a key factor for successful stamping. Harder metals may require more powerful presses or specialized techniques.

Power Hammer Stamping

Power hammer stamping employs a pneumatic or electric hammer to strike metal blanks with greater force and speed than hand stamping. This method offers a balance between the precision of machine stamping and the artistic control of hand stamping. It allows for creating more substantial, three-dimensional forms than hand stamping, while still maintaining a higher degree of customization than fully automated machine stamping.

The cost is intermediate between hand and machine stamping. Suitable metals are similar to hand stamping, but the increased force allows for working with slightly harder materials.

| Technique | Advantages | Disadvantages | Suitable Metals |

|---|---|---|---|

| Hand Stamping | High artistic control, personalization, low initial investment | Low production volume, labor-intensive, higher cost per piece | Copper, silver, brass, soft gold alloys |

| Machine Stamping | High production volume, high precision, efficiency | High initial investment, less design flexibility, less artistic control | Copper, silver, brass, some harder alloys (with appropriate tooling) |

| Power Hammer Stamping | Balance of precision and artistic control, higher production volume than hand stamping, ability to create three-dimensional forms | Higher initial investment than hand stamping, lower production volume than machine stamping | Copper, silver, brass, some harder alloys (than hand stamping) |

Tools and Materials for Metal Stamping

Successfully stamping metal jewelry requires the right tools and materials. Choosing the correct equipment is crucial for achieving clean, crisp impressions and preventing damage to both your materials and yourself. This section details the essential tools, material selection, and safety precautions necessary for a safe and productive stamping experience.

Gathering the necessary tools and materials before beginning any metal stamping project is paramount. This ensures a smooth workflow and prevents interruptions.

Essential Tools and Materials

A basic metal stamping setup requires several key tools. These tools, when used correctly, allow for precise and controlled stamping, leading to high-quality results.

- Metal Stamps: These come in various sizes, fonts, and designs. Choosing stamps made of hardened steel ensures durability and longevity.

- Steel Hammers: A variety of hammer weights are useful. Lighter hammers (e.g., 2-4 ounces) are ideal for softer metals and delicate work, while heavier hammers (e.g., 8-12 ounces) are better suited for harder metals and more forceful stamping.

- Metal Blanks: These are the pieces of metal you’ll be stamping. Common metals include brass, copper, and silver. Thickness varies depending on the design and desired outcome; thinner blanks are easier to stamp but can bend more easily.

- Safety Glasses: Protecting your eyes from flying metal fragments is critical. Always wear safety glasses during stamping.

- Metal Stamping Block: A sturdy block of steel or hard wood provides a stable surface for stamping, preventing damage to the stamps and ensuring even impressions.

- Optional Tools: These can enhance your work, including a chasing hammer for finer detail work, a jeweler’s saw for cutting metal, files for smoothing edges, and various polishing materials.

Hammer and Stamp Selection

The selection of hammers and stamps directly impacts the quality and success of your stamping projects. Consider the following factors when making your choices.

- Metal Hardness: Softer metals like copper and brass require lighter hammers and less forceful strikes to avoid damage. Harder metals like steel require heavier hammers and more forceful strikes.

- Stamp Design: Intricate designs require smaller, more precise stamps and lighter hammer blows. Larger, bolder designs can tolerate larger stamps and heavier hammers.

- Stamp Material: Hardened steel stamps are essential for durability and consistent impressions. Avoid using soft metal stamps, as they will deform quickly.

- Hammer Weight: Experiment with different hammer weights to find the optimal balance between force and control. Start with a lighter hammer and increase weight only if needed.

Safety Precautions and Techniques

Safety is paramount in metal stamping. Following proper techniques and using appropriate safety equipment minimizes the risk of injury.

- Always wear safety glasses: Metal fragments can fly off during stamping, potentially causing serious eye injuries.

- Use a stable work surface: A sturdy workbench or table prevents the metal blank from shifting during stamping, leading to uneven impressions or injury.

- Maintain proper posture: Avoid hunching over your work. Maintain a comfortable and upright posture to prevent strain and fatigue.

- Use controlled strikes: Avoid forceful, uncontrolled hammer blows. Gentle, controlled strikes produce cleaner impressions and reduce the risk of damaging the metal or the stamp.

- Work in a well-ventilated area: Some metals produce fumes during stamping. Ensure adequate ventilation to avoid inhaling harmful particles.

Proper Grip and Striking Techniques

The following description illustrates the proper grip and striking technique for hand stamping. Correct technique is crucial for consistent results and injury prevention.

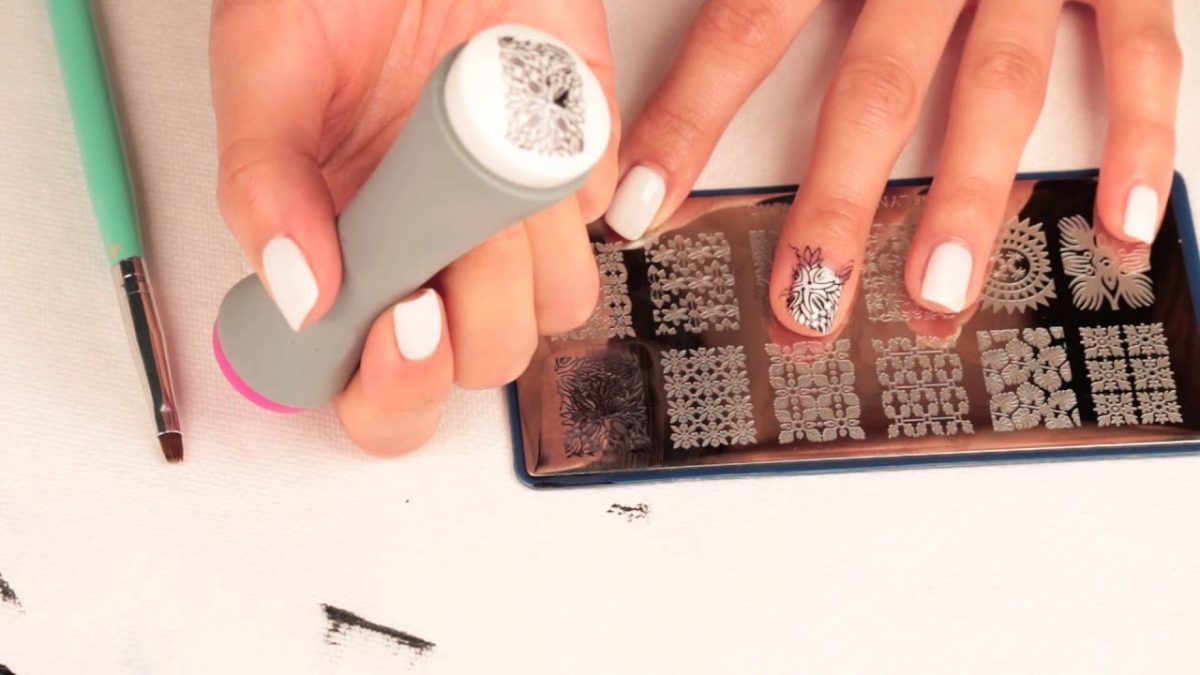

Visual Guide Description: The image shows a person standing with good posture, slightly bending at the knees. Their hands are positioned firmly on the hammer and the metal blank. The hammer is held with a relaxed but firm grip, using the entire hand and not just the fingertips. The metal blank is held securely on the stamping block with the non-dominant hand.

The striking action is smooth and controlled, with the hammer moving in a straight line from the shoulder, not just the wrist or forearm. The image clearly depicts a relaxed yet focused demeanor, emphasizing the importance of a controlled and deliberate movement. The angle of the hammer’s strike is perpendicular to the metal blank, ensuring even contact across the stamp’s surface.

The image also demonstrates the appropriate distance between the hands, ensuring a controlled and safe swing.

Metal Preparation and Design Transfer

Preparing your metal blanks and transferring your design are crucial steps in achieving a successful metal stamping project. Proper preparation ensures the metal is receptive to the stamping process, preventing damage and yielding clean, crisp impressions. Accurate design transfer guarantees the final piece matches your vision.Metal preparation involves several key stages to optimize the stamping process and achieve the desired results.

The choice of method will depend on the metal type and desired outcome.

Metal Blank Preparation

Preparing the metal blank involves cleaning, annealing, and surface preparation. Cleaning removes any dirt, grease, or oils that might interfere with the stamping process or prevent the transfer medium from adhering properly. Annealing softens the metal, making it more malleable and less prone to cracking or breaking during stamping. Surface preparation ensures a smooth, even surface for optimal design transfer and a consistent stamped impression.

- Cleaning: Use a soft brush and mild detergent to remove any visible dirt or debris. For stubborn contaminants, consider an ultrasonic cleaner. Thorough rinsing with distilled water is essential to remove all traces of cleaning agents.

- Annealing: This heat treatment process softens the metal. The specific temperature and duration depend on the metal type. For example, copper and brass typically require lower annealing temperatures than steel. After annealing, allow the metal to cool slowly to prevent warping or cracking.

- Surface Preparation: This might involve sanding with progressively finer grits of sandpaper to achieve a smooth surface, or using a polishing compound for a high-luster finish before stamping. The goal is to create a consistent surface for even ink or paint transfer.

Design Transfer Methods

Several methods exist for transferring designs onto metal blanks, each offering varying levels of precision and complexity. The chosen method will depend on the design’s intricacy, the stamper’s skill level, and the desired level of detail.

- Freehand Drawing: This method requires artistic skill and a steady hand. A fine-tipped permanent marker or etching pencil is used to draw the design directly onto the metal blank. This method is best suited for simple designs or those with a more organic feel.

- Stenciling: This method uses a stencil to create a precise Artikel of the design. The stencil can be cut from a material such as cardstock or acetate, then taped securely to the metal blank. Paint, ink, or a specialized transfer medium can be applied within the stencil openings. This technique is ideal for intricate designs that require accuracy and consistency.

- Transfer Paper: This method uses special transfer paper designed for metal stamping. The design is printed onto the transfer paper, then carefully traced onto the metal blank using a stylus or blunt tool. This technique provides a clean and accurate transfer of complex designs.

Metal Thickness and Blank Size Selection

The thickness of the metal blank significantly impacts the stamping results. Thicker metal requires more force to create a deep impression, and may require a larger, more robust hammer. Thinner metal is easier to stamp but is more prone to bending or warping. The blank size should be sufficiently large to accommodate the design and provide ample material for handling.

Choosing the right size and thickness is essential for a successful stamping project. Too thin, and the metal might bend or break; too thick, and the impression may be shallow or uneven.

Step-by-Step Guide: Preparing a Metal Blank and Transferring a Simple Design

The following steps Artikel the process of preparing a metal blank and transferring a simple design using transfer paper. Remember to always wear appropriate safety gear, including eye protection.

- Clean the metal blank thoroughly using a soft brush and mild detergent, followed by a thorough rinse.

- Print the design onto transfer paper, ensuring the image is reversed for a correct final impression.

- Carefully position the transfer paper onto the metal blank, securing it with tape to prevent movement.

- Trace over the design firmly using a stylus or blunt tool, applying even pressure to transfer the image onto the metal.

- Carefully remove the transfer paper to reveal the transferred design.

Stamping Techniques and Best Practices

Metal stamping, while seemingly straightforward, requires precision and technique to achieve consistently clean and crisp impressions. Mastering these techniques ensures professional-looking results and minimizes wasted materials. This section details the process, common pitfalls, and best practices for successful metal stamping.

Hand Stamping a Simple Design

The following steps illustrate the process of hand stamping a simple design, such as a heart, onto a metal blank. Assume the metal blank has already been annealed and cleaned as previously described.

- Positioning the Blank: Securely hold the metal blank using pliers or a bench block, ensuring the area to be stamped is easily accessible and stable. Avoid gripping the area directly where you’ll be stamping.

- Placement of the Stamp: Carefully position the stamp over the desired area of the blank. Ensure the stamp is perfectly aligned with your intended design. Use a light touch initially to avoid accidental misplacement.

- Striking the Stamp: Using a hammer, strike the stamp firmly and squarely with controlled force. Avoid glancing blows which can lead to uneven impressions. The force required will vary depending on the metal type and stamp size.

- Multiple Strikes (if needed): For deeper impressions, multiple strikes may be necessary. Each strike should be precisely aligned with the previous one to maintain a consistent and clean impression. Too much force at once may damage the metal.

- Inspection and Refinement: After each strike, inspect the impression. If necessary, make minor adjustments to achieve the desired depth and clarity. Avoid excessive force, which can lead to damage.

Common Mistakes and Solutions

Several common errors can affect the quality of stamped metal jewelry. Addressing these issues proactively will significantly improve your results.

- Uneven Impressions: This is often caused by inconsistent hammer blows or an unstable work surface. Solution: Use a stable bench block and practice consistent, controlled hammer strikes.

- Distorted Metal: Excessive force or improper metal preparation can lead to distortion. Solution: Use appropriate force for the metal type and ensure the metal is properly annealed.

- Blurred or Faint Impressions: This can result from a dull stamp, insufficient force, or improper metal preparation. Solution: Sharpen or replace dull stamps, increase striking force appropriately, and ensure the metal surface is clean and free from contaminants.

- Misaligned Stamps: Poor placement or movement during stamping leads to misalignment. Solution: Use a stable work surface, accurately position the stamp before striking, and avoid shifting the metal during the process.

Comparison of Stamping on Different Metals

The same design and force applied to different metals will yield varying results. For instance, softer metals like copper will show deeper impressions with less force compared to harder metals like silver or brass. Copper often shows more readily visible hammer marks. Brass may require more force and show less readily visible hammer marks, but can still yield a crisp impression.

Silver, while relatively malleable, will require careful control to prevent distortion, and will produce a sharp, clean impression with proper technique.

Best Practices Checklist

A comprehensive checklist helps ensure consistently high-quality results.

- Proper Metal Preparation: Anneal the metal to increase malleability and clean the surface thoroughly.

- Stable Work Surface: Use a sturdy bench block to provide a stable base for stamping.

- Controlled Hammer Strikes: Use consistent and controlled force to avoid uneven impressions or distortion.

- Sharp Stamps: Use sharp stamps to ensure crisp, clear impressions.

- Proper Alignment: Carefully align the stamp before each strike.

- Regular Inspection: Inspect the impression after each strike to monitor progress and make adjustments as needed.

- Appropriate Force: Adjust the force according to the metal type and desired impression depth.

Finishing and Aftercare of Stamped Metal Jewelry: How Do You Stamp Metal Jewelry

Giving your stamped metal jewelry a professional finish significantly enhances its aesthetic appeal and longevity. Proper aftercare ensures your creations remain beautiful and tarnish-free for years to come. This section details various finishing techniques and provides practical advice for cleaning, maintenance, and storage.

Finishing Techniques for Stamped Metal Jewelry

Several finishing techniques can transform the look and feel of stamped metal jewelry. These range from simple polishing to more complex processes like patination and plating, each offering unique advantages depending on the metal and desired effect.

Polishing

Polishing is a fundamental finishing technique used to smooth the surface of the metal, enhancing its shine and removing any imperfections left by the stamping process. Different polishing methods exist, ranging from hand-polishing with various grades of sandpaper and polishing cloths to using rotary tools with polishing compounds. Hand-polishing offers more control and precision, particularly for intricate designs, while rotary tools are faster for larger pieces.

The choice depends on the scale and complexity of the jewelry.

Patination

Patination involves applying a chemical solution to the metal’s surface to create a colored, aged, or antique effect. This technique is particularly popular with copper, brass, and silver, allowing for a wide array of colors and finishes. The process involves carefully applying the patina solution, then neutralizing it and sealing the finish to prevent further oxidation. Liver of sulfur is a common patination solution for creating dark, antique-looking finishes on silver.

Plating

Plating involves coating the stamped metal with a thin layer of another metal, such as gold, silver, or rhodium. This process enhances the jewelry’s durability, resistance to tarnish, and overall aesthetic appeal. Electroplating is a common method, using an electric current to deposit the plating metal onto the stamped piece. Plating offers superior protection against tarnishing and adds a luxurious touch to the final product.

Cleaning and Maintaining Stamped Metal Jewelry

Regular cleaning and proper care are essential to prevent tarnishing and damage to your stamped metal jewelry. Avoid harsh chemicals and abrasive cleaners. For most metals, a gentle cleaning with warm soapy water and a soft cloth is sufficient. For more stubborn tarnish, a specialized jewelry cleaning solution can be used according to the manufacturer’s instructions.

Storing Stamped Jewelry

Proper storage is crucial for preserving the beauty and longevity of your stamped jewelry. Individual storage is ideal to prevent scratching. Soft pouches or fabric-lined boxes are excellent choices. Avoid storing jewelry in damp or humid environments, as this can accelerate tarnishing. Consider using anti-tarnish strips or bags in storage containers to further protect your pieces.

Finishing Techniques Comparison

| Finishing Technique | Description | Suitable Metals | Advantages | Disadvantages |

|---|---|---|---|---|

| Polishing | Smoothing the metal surface to enhance shine. | Most metals (silver, gold, copper, brass) | Enhances shine, removes imperfections. | Can be time-consuming, may remove detail in intricate designs. |

| Patination | Applying a chemical solution to create a colored or aged effect. | Copper, brass, silver | Creates unique antique or aged look. | Requires careful application and sealing, can be messy. |

| Plating | Coating the metal with a thin layer of another metal. | Most metals | Increases durability, resists tarnish, enhances appearance. | Can be expensive, plating may wear off over time. |

Creating stamped metal jewelry is a rewarding experience that blends artistry, precision, and technical skill. By understanding the different techniques, mastering the tools, and following best practices, you can transform simple metal blanks into unique and enduring pieces. Whether you’re a seasoned artisan or a curious beginner, the world of metal stamping offers endless creative possibilities. Remember to prioritize safety, experiment with different metals and designs, and enjoy the process of bringing your jewelry visions to life.

The journey of learning and creating is just as important as the final product itself. Embrace the challenges, celebrate the successes, and let your creativity shine.

Popular Questions

What type of hammer is best for hand stamping soft metals like copper?

A softer hammer, like a nylon or rawhide mallet, is ideal for preventing damage to softer metals.

Can I stamp on already finished jewelry pieces?

It’s generally difficult and can damage the existing finish. It’s best to stamp on blanks before finishing.

How do I prevent my stamped jewelry from tarnishing?

Use a clear sealant or apply a protective coating after finishing. Proper storage also helps.

What is annealing and why is it important?

Annealing is a heat-treating process that softens the metal, making it more malleable and less prone to cracking during stamping.