How a 2 strome engine works – How a 2-stroke engine works is a question that has intrigued mechanics and enthusiasts alike for decades. These compact powerhouses, often found in motorcycles, boats, and lawnmowers, operate on a simple yet efficient principle. Unlike their four-stroke counterparts, two-stroke engines complete their power cycle in just two strokes of the piston, leading to a more compact design and a burst of raw power.

This guide will delve into the intricate workings of a 2-stroke engine, exploring its unique design, the fuel-oil mixture, the ignition system, and the remarkable power it generates. From the fundamental principles to the everyday maintenance tips, we’ll unravel the secrets behind this fascinating engine technology.

Introduction to Two-Stroke Engines: How A 2 Strome Engine Works

A two-stroke engine is a type of internal combustion engine that completes its power cycle in one revolution of the crankshaft, unlike a four-stroke engine which requires two revolutions. This difference stems from the way the two-stroke engine handles the intake and exhaust processes, which occur simultaneously within a single stroke.Two-stroke engines are known for their simplicity and power-to-weight ratio, making them suitable for applications requiring high power output in compact packages.

However, they also present certain disadvantages compared to four-stroke engines, particularly in terms of fuel efficiency and emissions.

Advantages and Disadvantages of Two-Stroke Engines

Two-stroke engines offer several advantages over their four-stroke counterparts:

- Power-to-weight ratio: Due to their simpler design, two-stroke engines can achieve higher power output for a given size and weight. This makes them ideal for applications like motorcycles, small boats, and power tools.

- Simplicity: Two-stroke engines have fewer moving parts compared to four-stroke engines, leading to a more straightforward design and reduced maintenance requirements.

- High power output: Two-stroke engines can generate high power output due to their efficient combustion process and ability to operate at higher RPMs.

However, two-stroke engines also have several disadvantages:

- Fuel efficiency: Two-stroke engines generally have lower fuel efficiency compared to four-stroke engines due to the transfer of unburnt fuel through the exhaust.

- Emissions: Two-stroke engines are known for producing higher levels of emissions, particularly hydrocarbons and particulate matter. This is due to the mixing of oil and fuel and the incomplete combustion process.

- Lubrication: Two-stroke engines require a pre-mix of oil and fuel for lubrication, which can lead to issues like oil fouling and increased maintenance.

Applications of Two-Stroke Engines

Two-stroke engines are widely used in various applications, leveraging their advantages in specific scenarios:

- Motorcycles: Two-stroke engines were once prevalent in motorcycles, especially smaller displacement models, due to their power-to-weight ratio and high RPM capabilities. While modern motorcycles predominantly use four-stroke engines, some niche manufacturers still produce two-stroke models.

- Outboard motors: Two-stroke engines are still common in outboard motors for boats, particularly smaller models. Their lightweight and high power output make them suitable for recreational boating and smaller fishing vessels.

- Power tools: Two-stroke engines power a wide range of power tools, including chainsaws, lawnmowers, and generators. Their compact size and high power output make them suitable for portable applications.

- Model aircraft and model boats: Two-stroke engines are popular for powering model aircraft and boats due to their high power-to-weight ratio and ability to operate at high RPMs.

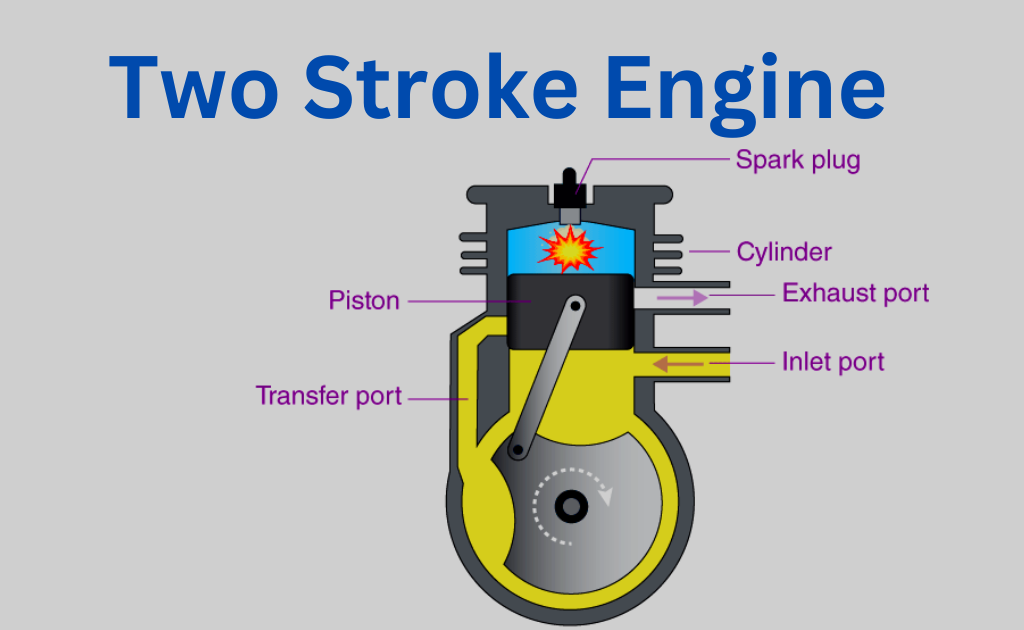

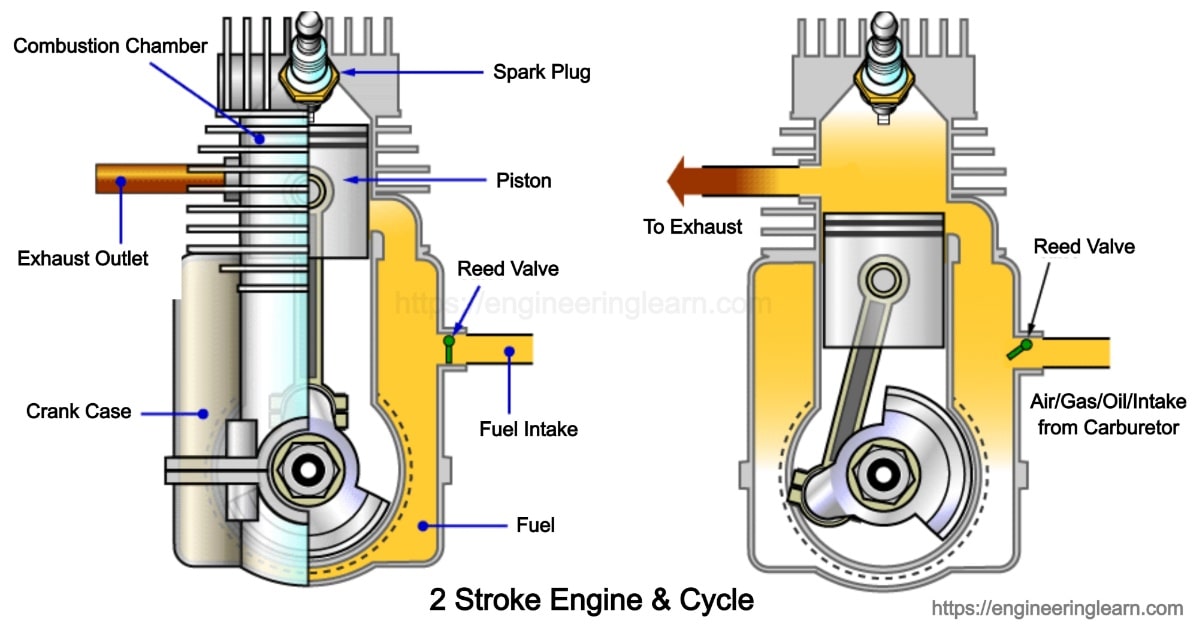

The Two-Stroke Cycle

The two-stroke cycle is a combustion process that powers many small engines, including those found in motorcycles, chainsaws, and lawnmowers. Unlike the four-stroke cycle, which completes its combustion process in four distinct strokes of the piston, the two-stroke cycle completes the process in just two strokes. This makes two-stroke engines simpler and lighter than their four-stroke counterparts, but it also results in higher emissions and reduced fuel efficiency.The two-stroke cycle involves four key stages: intake, compression, power, and exhaust.

These stages occur rapidly and seamlessly within the two strokes of the piston. The process is driven by the movement of the piston, which compresses the fuel-air mixture, ignites it, and then expels the exhaust gases.

The Role of Transfer and Exhaust Ports

The transfer and exhaust ports are crucial components of the two-stroke engine that facilitate the intake and exhaust processes. These ports are strategically placed in the engine cylinder wall and open and close at specific points in the piston’s travel.

- Intake: As the piston moves downward during the intake stroke, the crankcase is filled with a fuel-air mixture through the intake port. The transfer port is closed at this stage, preventing the mixture from entering the combustion chamber. The crankcase acts as a pump, creating a vacuum that draws the fuel-air mixture into the crankcase.

- Compression: As the piston moves upward, the transfer port opens, allowing the fuel-air mixture from the crankcase to flow into the combustion chamber. The exhaust port remains closed at this stage, sealing the chamber. The piston compresses the fuel-air mixture in the combustion chamber.

- Power: When the piston reaches its highest point, the spark plug ignites the compressed fuel-air mixture, creating a rapid expansion of hot gases. This expansion pushes the piston down, generating power. The exhaust port remains closed during this stage, allowing the combustion to occur within the sealed chamber.

- Exhaust: As the piston moves down, the exhaust port opens, allowing the burned gases to escape from the combustion chamber. The transfer port also opens at this stage, allowing a fresh fuel-air mixture to enter the crankcase, preparing for the next cycle.

The Crankcase as a Pump

The crankcase plays a vital role in the two-stroke cycle, acting as a pump to draw in the fuel-air mixture. The piston’s downward movement creates a vacuum in the crankcase, which draws the fuel-air mixture through the intake port. The transfer port then allows this mixture to flow into the combustion chamber during the compression stroke.

The crankcase acts as a pump, creating a vacuum that draws the fuel-air mixture into the crankcase.

This pumping action is crucial for the efficient operation of the two-stroke engine. It ensures that the combustion chamber is filled with a fresh fuel-air mixture for each cycle, allowing for continuous combustion and power generation.

Fuel and Lubrication

Two-stroke engines require a mixture of fuel and oil for proper operation. Unlike four-stroke engines, which have a separate lubrication system, two-stroke engines rely on the fuel-oil mixture to lubricate the moving parts. The oil is mixed with the fuel before entering the combustion chamber, where it burns along with the fuel.

Mixing Fuel and Oil

The correct fuel-oil mixture ratio is crucial for the proper operation and longevity of a two-stroke engine. A too-lean mixture (too much fuel, not enough oil) can lead to engine damage due to insufficient lubrication, while a too-rich mixture (too much oil, not enough fuel) can result in excessive smoke and fouling of spark plugs. The recommended mixture ratio is typically specified by the engine manufacturer and is usually expressed as a ratio of fuel to oil, such as 50:1 or 40:1.

For example, a 50:1 mixture means that for every 50 parts of fuel, there is 1 part of oil.

Pre-Mixing Fuel and Oil

Pre-mixing fuel and oil is the most common method of lubrication for two-stroke engines. This involves mixing the fuel and oil together in a separate container before filling the engine’s fuel tank. This method is relatively simple and inexpensive, but it requires careful attention to the mixture ratio.

Advantages of Pre-Mixing

- Simple and inexpensive

- Provides consistent lubrication

- Suitable for engines with limited space

Disadvantages of Pre-Mixing

- Requires careful attention to mixture ratio

- Can be messy and time-consuming

- Not suitable for engines with high-performance requirements

Separate Lubrication System

Some two-stroke engines, particularly high-performance models, use a separate lubrication system. This system injects oil directly into the engine’s crankcase, eliminating the need for pre-mixing.

Advantages of Separate Lubrication System

- Provides precise oil delivery

- Allows for different oil types and viscosity

- Suitable for high-performance engines

Disadvantages of Separate Lubrication System

- More complex and expensive

- Requires regular maintenance

- Can be prone to malfunctions

Types of Two-Stroke Engine Oils

Two-stroke engine oils are specially formulated to withstand the high temperatures and pressures encountered in the combustion chamber. They contain additives that provide lubrication, deter wear, and prevent fouling.

Types of Two-Stroke Engine Oils

- Mineral oil: The most common type of two-stroke oil, mineral oil is derived from crude oil and is relatively inexpensive. However, it can break down at high temperatures and leave deposits in the engine.

- Synthetic oil: Synthetic oils are manufactured from chemically engineered compounds and offer better performance than mineral oils. They are more resistant to breakdown at high temperatures and provide better lubrication and wear protection.

- Biodegradable oil: Biodegradable oils are made from renewable sources, such as vegetable oils, and are designed to decompose in the environment. They are often used in engines that operate in sensitive areas, such as lakes and rivers.

Choosing the Right Oil

The type of two-stroke engine oil you choose will depend on the engine’s requirements, operating conditions, and your budget. It’s important to consult the engine manufacturer’s recommendations for the appropriate oil type and mixture ratio.

Ignition and Combustion

The ignition system in a two-stroke engine is responsible for initiating the combustion process that drives the engine. This system consists of a spark plug, an ignition coil, and a timing mechanism.The combustion process in a two-stroke engine is similar to that in a four-stroke engine, but it occurs in a single stroke. When the spark plug ignites the fuel-air mixture, the resulting explosion drives the piston downwards, generating power.

The combustion process is critical for the efficient operation of a two-stroke engine, and several factors can affect its efficiency.

Spark Plug and Ignition Timing

The spark plug is a key component of the ignition system, delivering the electrical spark that ignites the fuel-air mixture. The spark plug consists of a central electrode and a ground electrode, separated by a gap. When high voltage is applied to the spark plug, it creates a spark across the gap, igniting the fuel-air mixture.Ignition timing refers to the precise moment when the spark plug ignites the fuel-air mixture.

This timing is crucial for optimal engine performance and is determined by the engine’s control system. The ignition timing is synchronized with the engine’s rotation, ensuring that the spark occurs at the correct moment for efficient combustion.

Combustion Process

The combustion process in a two-stroke engine is initiated by the spark plug, which ignites the fuel-air mixture in the combustion chamber. This ignition creates a rapid increase in pressure and temperature, driving the piston downwards.The combustion process in a two-stroke engine is influenced by various factors, including:

- Fuel-air mixture: The ratio of fuel to air in the mixture significantly affects combustion efficiency. A rich mixture (high fuel content) can lead to incomplete combustion and increased emissions, while a lean mixture (low fuel content) can cause detonation or pre-ignition.

- Compression ratio: The compression ratio is the ratio of the volume of the combustion chamber at the bottom dead center (BDC) to the volume at the top dead center (TDC). A higher compression ratio results in higher pressure and temperature during combustion, leading to increased efficiency.

- Spark plug location and design: The location and design of the spark plug affect the flame propagation and combustion efficiency. A centrally located spark plug with a suitable electrode design promotes efficient flame propagation.

- Engine speed and load: The combustion process is influenced by engine speed and load. At higher speeds and loads, the combustion process needs to be faster and more efficient to maintain optimal performance.

Factors Affecting Combustion Efficiency, How a 2 strome engine works

Several factors can influence the combustion efficiency in a two-stroke engine:

- Spark plug condition: A worn-out or fouled spark plug can hinder efficient combustion. A clean and properly gapped spark plug is essential for reliable ignition.

- Ignition timing: Precise ignition timing is crucial for efficient combustion. Incorrect timing can lead to incomplete combustion or detonation.

- Fuel quality: The quality of the fuel used can significantly affect combustion efficiency. High-octane fuels are generally recommended for two-stroke engines to prevent detonation.

- Air intake system: A clean and efficient air intake system ensures that the engine receives the necessary amount of air for combustion. A clogged air filter or other restrictions can reduce combustion efficiency.

- Exhaust system: The exhaust system plays a role in scavenging and expelling exhaust gases, influencing combustion efficiency. A properly functioning exhaust system ensures efficient removal of exhaust gases and helps maintain optimal combustion conditions.

Cooling and Exhaust

Two-stroke engines, known for their compact design and power output, require efficient cooling systems to manage the heat generated during combustion. The exhaust system plays a crucial role in removing combustion products and reducing emissions, contributing to the overall performance and environmental impact of these engines.

Air Cooling

Air cooling is the most common method employed in two-stroke engines, particularly in smaller applications like motorcycles and lawnmowers. This method relies on the natural convection of air to dissipate heat from the engine components.

- Finned surfaces: Engine components like the cylinder head and cylinder barrel are designed with fins to increase the surface area exposed to air, enhancing heat transfer.

- Fan-assisted cooling: In some cases, a fan is incorporated to improve air circulation and accelerate the cooling process, especially in applications where high engine speeds are common.

Air cooling is a simple and cost-effective solution, but its effectiveness can be limited in high-temperature environments or during sustained high-load operation.

Liquid Cooling

Liquid cooling systems, commonly found in larger two-stroke engines like marine outboards and some motorcycles, provide a more efficient method of heat dissipation.

- Coolant circulation: A liquid coolant, usually water mixed with antifreeze, circulates through channels within the engine block, absorbing heat from critical components.

- Radiator and fan: The heated coolant is then passed through a radiator, where a fan helps to cool the coolant before it circulates back to the engine.

Liquid cooling systems offer superior heat management, allowing for higher engine power output and improved performance in demanding conditions.

Exhaust System

The exhaust system in a two-stroke engine is designed to remove combustion gases and manage pressure fluctuations within the cylinder.

- Exhaust port: The exhaust port is strategically positioned on the cylinder wall to allow for the controlled expulsion of combustion gases during the power stroke.

- Exhaust manifold: The exhaust port connects to an exhaust manifold, which directs the exhaust gases to the muffler or silencer.

- Muffler: The muffler serves to reduce the noise level of the exhaust gases and, in some cases, incorporates a catalytic converter to reduce harmful emissions.

The design of the exhaust system can significantly impact engine performance and emissions.

Environmental Impact

Two-stroke engines have historically been associated with higher emissions compared to their four-stroke counterparts.

- Unburned hydrocarbons: The inherent design of two-stroke engines can lead to higher levels of unburned hydrocarbons (HC) in the exhaust.

- Particulate matter: Two-stroke engines can also emit significant amounts of particulate matter (PM), contributing to air pollution.

To address these environmental concerns, manufacturers have implemented various measures, including:

- Catalytic converters: Catalytic converters are employed in many two-stroke engines to reduce harmful emissions, particularly HC and carbon monoxide (CO).

- Fuel injection: Modern two-stroke engines often utilize fuel injection systems, which provide precise fuel metering and reduce fuel consumption, contributing to lower emissions.

- Engine design improvements: Advanced engine designs incorporate features like improved scavenging systems and optimized exhaust port timing to enhance combustion efficiency and reduce emissions.

These advancements have significantly reduced the environmental impact of two-stroke engines, making them a more viable option in various applications.

Common Two-Stroke Engine Components

Two-stroke engines are known for their simplicity and power-to-weight ratio. These engines consist of a few key components that work together to produce motion. Each component plays a vital role in the overall operation of the engine.

Crankshaft

The crankshaft is the heart of the engine, responsible for converting the linear motion of the piston into rotational motion. It is a steel shaft with offset journals (cranks) that are connected to the connecting rod. The crankshaft rotates within bearings, allowing it to transmit power to the transmission or other connected components. The crankshaft also houses the flywheel, which helps smooth out engine operation and store rotational energy.

Connecting Rod

The connecting rod is a strong, lightweight component that connects the piston to the crankshaft. It allows the piston to translate its linear motion into rotational motion at the crankshaft. The connecting rod has a small end that attaches to the piston pin and a large end that connects to the crankshaft journal. The connecting rod is designed to withstand high stresses and loads during engine operation.

Piston

The piston is a cylindrical component that moves up and down within the cylinder. It is driven by the expanding gases produced during combustion. The piston has a head that is designed to seal the combustion chamber and a skirt that reduces friction against the cylinder walls. The piston is also equipped with piston rings, which help to seal the combustion chamber and prevent oil from entering the combustion process.

Cylinder

The cylinder is a hollow, cylindrical component that houses the piston. It is machined to a precise tolerance to ensure a tight fit for the piston and rings. The cylinder is also equipped with ports, which are openings that allow fuel and air to enter the combustion chamber and exhaust gases to exit. The cylinder is often made of cast iron or aluminum, depending on the engine’s operating conditions.

Carburetor

The carburetor is responsible for mixing fuel and air in the correct proportions for combustion. It uses a venturi effect to draw air into the carburetor, which then mixes with fuel from the fuel bowl. The carburetor is equipped with a throttle valve that controls the amount of air and fuel entering the engine, thereby regulating engine speed.

Muffler

The muffler is a component designed to reduce noise from the engine exhaust. It is typically a chamber filled with baffles or other sound-absorbing materials. The muffler is connected to the exhaust port of the cylinder and allows exhaust gases to exit the engine while reducing the noise level.

Maintenance and Troubleshooting

Two-stroke engines, known for their simplicity and power, require regular maintenance to ensure optimal performance and longevity. Troubleshooting common issues can help diagnose and resolve problems, keeping your engine running smoothly.

Common Maintenance Tasks

Regular maintenance is crucial for maintaining the health and performance of your two-stroke engine. These tasks are relatively straightforward and can be performed by most individuals with basic mechanical skills.

- Spark Plug Replacement: The spark plug ignites the fuel-air mixture, and a worn or fouled spark plug can cause starting difficulties, misfires, and reduced power. It’s recommended to replace the spark plug every 50-100 hours of operation or as per the manufacturer’s recommendations.

- Carburetor Cleaning: The carburetor mixes fuel and air, and over time, deposits can accumulate, leading to poor fuel flow and engine performance. Regular cleaning ensures proper fuel-air mixture and optimal combustion.

- Air Filter Replacement: The air filter prevents dirt and debris from entering the engine, protecting internal components from wear and tear. A clogged air filter restricts airflow, reducing engine power and fuel efficiency. It’s advisable to replace the air filter every 25-50 hours of operation or as recommended by the manufacturer.

- Fuel System Cleaning: The fuel system, including the fuel lines and tank, can become contaminated with deposits, affecting fuel flow and engine performance. Periodic cleaning of the fuel system helps maintain optimal fuel delivery.

- Lubrication System Check: Two-stroke engines require a pre-mixed fuel and oil mixture for lubrication. Ensure the oil-to-fuel ratio is correct, as incorrect ratios can lead to engine damage. Regularly check the oil level and top up as needed.

Troubleshooting Common Issues

Two-stroke engines can experience various issues, but many can be resolved with proper diagnosis and troubleshooting.

- Engine Stalling: Stalling can be caused by several factors, including a fouled spark plug, clogged carburetor, fuel system issues, or a faulty ignition system. Check the spark plug, clean the carburetor, inspect the fuel lines and tank, and examine the ignition system for any problems.

- Excessive Smoking: Excessive smoke can indicate problems with the fuel mixture, engine wear, or a faulty piston ring. Check the oil-to-fuel ratio, inspect the engine for signs of wear, and replace worn piston rings if necessary.

- Loss of Power: Loss of power can result from a clogged air filter, a fouled spark plug, a fuel mixture problem, or engine wear. Inspect the air filter, replace the spark plug if needed, check the fuel mixture, and assess the engine for signs of wear.

Identifying and Addressing Fuel Mixture Problems

The correct fuel mixture is crucial for optimal performance and engine longevity. An incorrect mixture can lead to various issues, including excessive smoking, engine damage, and reduced power.

- Too Rich Mixture: A too-rich mixture contains too much oil, leading to excessive smoke, fouled spark plugs, and reduced power. Adjust the oil-to-fuel ratio by reducing the oil concentration.

- Too Lean Mixture: A too-lean mixture contains too little oil, leading to increased engine wear, overheating, and potential engine damage. Adjust the oil-to-fuel ratio by increasing the oil concentration.

Troubleshooting Ignition System Problems

The ignition system provides the spark that ignites the fuel-air mixture, and problems with the ignition system can lead to starting difficulties, misfires, and reduced power.

- Faulty Spark Plug: A worn or fouled spark plug can cause misfires, reduced power, and starting difficulties. Inspect the spark plug for wear or fouling and replace it if necessary.

- Faulty Ignition Coil: The ignition coil generates the high voltage needed to create a spark. A faulty ignition coil can prevent spark generation, leading to engine failure. Inspect the ignition coil for any damage or signs of wear.

- Faulty Ignition Switch: The ignition switch controls the flow of electricity to the ignition system. A faulty ignition switch can prevent the engine from starting. Inspect the ignition switch for any damage or signs of wear.

Troubleshooting Cooling System Problems

Two-stroke engines generate heat during operation, and the cooling system helps dissipate this heat to prevent engine damage.

- Clogged Cooling Fins: The cooling fins on the engine cylinder help dissipate heat. Clogged fins can restrict airflow, leading to engine overheating. Clean the cooling fins regularly to ensure proper airflow.

- Faulty Cooling System: The cooling system can include a fan, water pump, or other components. A faulty cooling system can lead to engine overheating. Inspect the cooling system for any damage or signs of wear.

Understanding the inner workings of a 2-stroke engine reveals a world of engineering brilliance. Its simplicity, power, and efficiency have made it a mainstay in various applications. As you’ve discovered, the 2-stroke engine is a testament to innovation and practicality. Whether you’re a seasoned mechanic or a curious newcomer, this guide has provided you with the knowledge to appreciate the power and finesse of this remarkable engine design.

Common Queries

Why do 2-stroke engines smoke?

2-stroke engines produce smoke due to the oil mixed with the fuel. This oil is burned during the combustion process, creating visible exhaust smoke.

What are the advantages of a 2-stroke engine?

2-stroke engines are known for their lightweight design, high power-to-weight ratio, and simpler construction compared to four-stroke engines.

What is the correct fuel-oil mixture for a 2-stroke engine?

The correct fuel-oil mixture varies depending on the engine model and manufacturer’s recommendations. Refer to your engine’s manual for the specific ratio.

How often should I change the spark plug in a 2-stroke engine?

Spark plug replacement intervals vary depending on usage and engine type. Consult your engine manual for recommended replacement intervals.

What are the common problems with 2-stroke engines?

Common issues include fuel mixture problems, ignition system malfunctions, carburetor problems, and excessive wear and tear on engine components.