Where are surelock security safes made – Ever wondered where those sturdy, impenetrable SureLock Security Safes are crafted? You’re not alone. It’s a question that piques the curiosity of anyone who values their valuables and wants to know the story behind the safekeeping. SureLock, a name synonymous with security, operates across a global network of manufacturing facilities, each contributing to the production of these robust safes.

From the choice of materials to the intricate manufacturing process, there’s a fascinating world behind every SureLock safe.

This exploration dives deep into the manufacturing process, unraveling the secrets behind the quality, innovation, and sustainability that define SureLock’s commitment to safeguarding your precious belongings. We’ll uncover the countries where SureLock’s production takes place, the materials used, and the stringent quality control measures implemented to ensure each safe meets the highest standards. Get ready to discover the hidden world behind the locked door of a SureLock Security Safe.

SureLock Security Safes: Where Are Surelock Security Safes Made

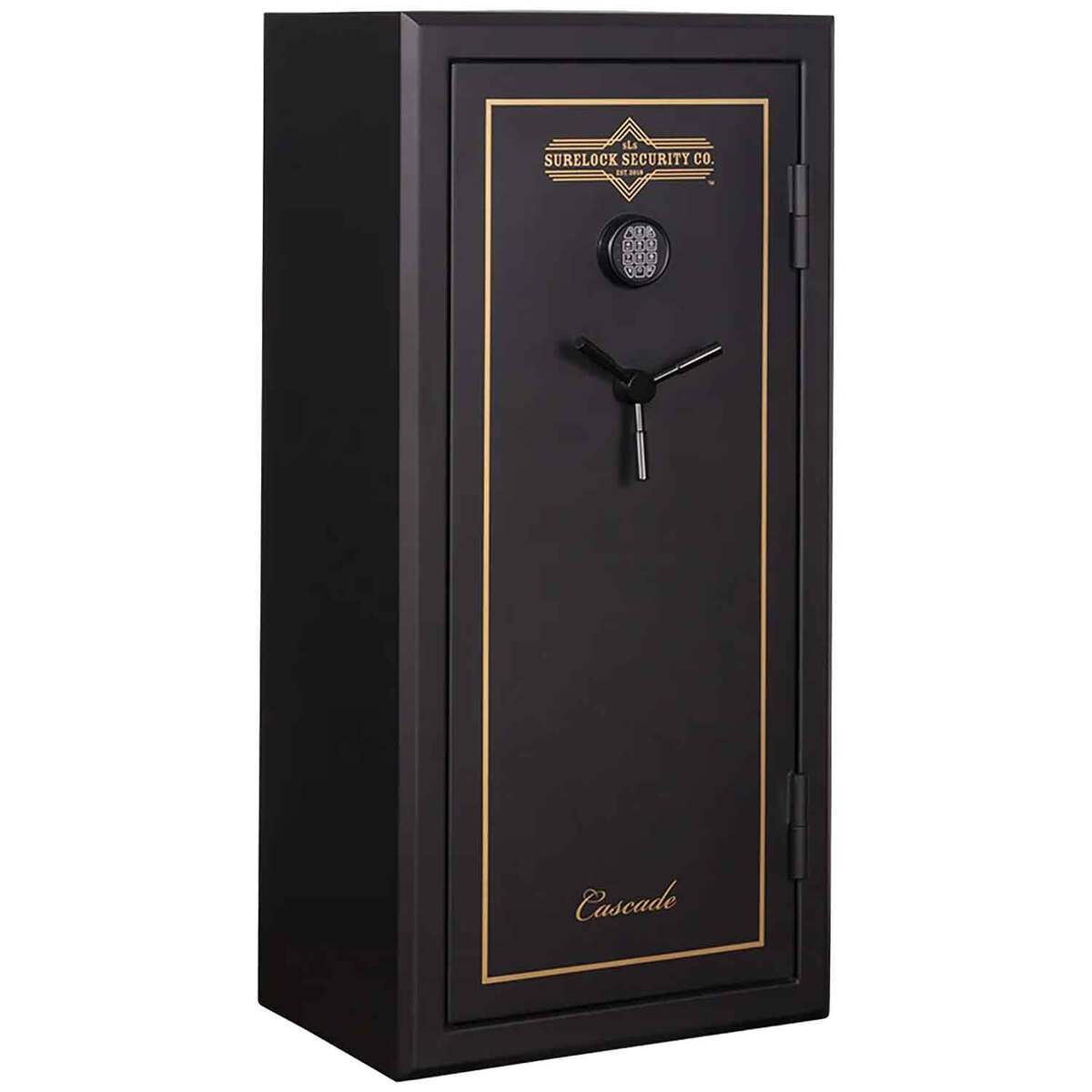

SureLock Security Safes are a global brand, renowned for their robust construction and advanced security features. Their safes are sought after by individuals, businesses, and institutions worldwide. This widespread demand necessitates a global manufacturing network to ensure timely production and distribution.

Manufacturing Locations

SureLock Security Safes maintains a global manufacturing network to cater to the diverse needs of its customers. The company has strategically chosen manufacturing locations based on various factors, including labor costs, proximity to raw materials, and access to skilled labor.

- China: SureLock’s largest manufacturing facility is located in Shenzhen, China. This facility boasts state-of-the-art equipment and a highly skilled workforce. The high volume of production in China allows SureLock to offer competitive pricing on a wide range of safes.

- Germany: SureLock has a smaller manufacturing facility in Germany, focusing on high-end, bespoke safes. This facility leverages Germany’s reputation for precision engineering and quality craftsmanship. German-made SureLock safes are often custom-designed to meet the specific security requirements of discerning clients.

- United States: SureLock operates a manufacturing facility in Ohio, USA. This facility primarily produces safes for the North American market. The Ohio facility emphasizes compliance with local safety standards and provides quick turnaround times for domestic customers.

Factors Influencing Manufacturing Location

The choice of manufacturing locations for SureLock Security Safes is influenced by a number of factors:

- Labor Costs: Labor costs are a significant factor in manufacturing. SureLock strategically chooses locations where labor costs are competitive without compromising on quality. For example, China’s lower labor costs allow for competitive pricing on mass-produced safes, while Germany’s skilled workforce is essential for producing high-end, bespoke safes.

- Proximity to Raw Materials: SureLock’s manufacturing facilities are located near sources of raw materials, such as steel and electronics components. This minimizes transportation costs and ensures a reliable supply chain.

- Access to Skilled Labor: SureLock requires a skilled workforce to manufacture its safes. The company chooses locations with a strong pool of skilled engineers, technicians, and metalworkers. Germany, with its long tradition of precision engineering, is an example of a location with a highly skilled workforce.

- Local Regulations and Standards: SureLock complies with local regulations and safety standards in each of its manufacturing locations. This ensures that its products meet the requirements of the markets they serve.

- Market Proximity: SureLock strategically positions its manufacturing facilities to serve specific markets. The Ohio facility, for example, caters to the North American market, while the Shenzhen facility serves the global market. This minimizes shipping costs and delivery times.

The Manufacturing Process

The creation of a SureLock Security Safe is a meticulous and multi-faceted process, requiring precision engineering and high-quality materials to ensure its strength and security. From initial design to final assembly, each step is carefully controlled to meet the highest standards of quality and performance.

Materials and their Quality

The materials used in the construction of SureLock Security Safes are carefully chosen for their strength, durability, and resistance to various forms of attack. The primary materials used include:

- Steel: The foundation of a SureLock Security Safe is its steel body, typically made from high-carbon steel, known for its strength and resistance to bending, cutting, and drilling. This steel is sourced from reputable manufacturers, ensuring consistent quality and reliability.

- Reinforced Concrete: To further enhance the safes’ resistance to brute force attacks, a layer of reinforced concrete is often incorporated within the steel body. This concrete is specifically formulated to be extremely dense and resistant to impact, providing an additional barrier against penetration attempts.

- Advanced Locking Mechanisms: The locking mechanisms used in SureLock Security Safes are designed to be highly resistant to manipulation and tampering. They are often constructed from hardened steel, with intricate internal components that resist picking, drilling, and other common methods of attack.

- Electronic Security Systems: Some SureLock Security Safes feature advanced electronic security systems, incorporating sophisticated technologies such as biometric authentication, motion sensors, and alarm systems. These systems are designed to detect and deter unauthorized access, providing an extra layer of security.

Manufacturing Process

The manufacturing process for SureLock Security Safes involves several distinct steps, each contributing to the final product’s strength, security, and reliability:

- Design and Engineering: The process begins with the design and engineering of the safe, taking into account the specific requirements and security needs of the customer. This involves creating detailed blueprints and specifications for the safe’s dimensions, materials, locking mechanisms, and any additional security features.

- Steel Fabrication: The steel body of the safe is fabricated using specialized machinery, such as laser cutters, bending machines, and welding equipment. These machines ensure precise cutting, shaping, and joining of the steel components, creating a strong and durable foundation for the safe.

- Concrete Casting: The reinforced concrete layer is cast within the steel body, creating a solid and impenetrable core. This process typically involves using a specialized mold to ensure the concrete is evenly distributed and properly reinforced with steel bars.

- Installation of Locking Mechanisms: The locking mechanisms are carefully installed within the safe’s door, ensuring they are securely integrated with the surrounding steel and concrete. This step requires precision and expertise to ensure the locking mechanisms function flawlessly and resist any attempts at tampering.

- Integration of Electronic Systems: If the safe includes electronic security systems, these are carefully integrated into the overall design. This may involve installing sensors, wiring, and control panels, ensuring they are seamlessly connected and function effectively.

- Final Assembly and Testing: Once all components are assembled, the safe undergoes rigorous testing to ensure it meets all safety and security standards. This may involve subjecting the safe to various stress tests, penetration attempts, and lock-picking simulations to verify its strength and resilience.

Key Technologies and Equipment

The manufacturing of SureLock Security Safes relies on a range of advanced technologies and equipment, contributing to the quality, precision, and security of the final product:

- Computer-Aided Design (CAD) Software: CAD software is used in the initial design phase, allowing engineers to create detailed 3D models of the safe and simulate its performance under various conditions. This ensures the safe is optimized for strength, security, and functionality.

- Laser Cutting Machines: Laser cutting machines are employed to precisely cut the steel components for the safe’s body. These machines offer high accuracy and speed, ensuring the steel pieces are cut to exact specifications, contributing to the safe’s overall structural integrity.

- Bending Machines: Bending machines are used to shape the steel components, creating curves and angles according to the safe’s design. These machines are capable of handling heavy steel pieces, ensuring the safe’s body is formed with precision and strength.

- Welding Equipment: Welding equipment is used to join the steel components together, creating a strong and seamless bond. Modern welding techniques, such as robotic welding, ensure high-quality welds that are resistant to stress and corrosion.

- Concrete Mixing and Pouring Equipment: Specialized concrete mixing and pouring equipment is used to create the reinforced concrete core of the safe. This equipment ensures the concrete is properly mixed and poured, creating a dense and impenetrable layer that adds to the safe’s overall security.

- Advanced Testing Equipment: To ensure the safe meets the highest standards of security, various testing equipment is used to evaluate its strength, resilience, and resistance to different types of attack. This may include impact testers, penetration tools, and lock-picking devices.

Quality Control and Safety Standards

SureLock Security Safes understands that the security and integrity of your valuables are paramount. Therefore, they prioritize quality control and adhere to stringent safety standards throughout the manufacturing process. These measures are essential to ensure that every safe leaving their facility meets the highest industry standards and provides the protection you deserve.

Quality Control Measures

Quality control measures are implemented at every stage of the manufacturing process to guarantee the reliability and durability of SureLock Security Safes.

- Raw Material Inspection: The journey begins with the careful selection and inspection of raw materials. Only high-quality steel, concrete, and other components are used, ensuring a strong and secure foundation for the safe.

- In-Process Inspections: Throughout the manufacturing process, skilled technicians conduct rigorous inspections at various stages. This ensures that each component meets the required specifications and is assembled correctly. These inspections include dimensional checks, weld quality assessments, and functionality tests.

- Final Inspection: Before a safe leaves the factory, it undergoes a comprehensive final inspection. This includes testing the locking mechanisms, ensuring proper door alignment, and verifying the overall structural integrity of the safe. Only safes that pass these stringent inspections are deemed ready for delivery.

Safety Standards and Certifications

SureLock Security Safes adheres to the highest safety standards and certifications, providing peace of mind to customers.

- UL Certification: Many SureLock Security Safes are UL certified, indicating they have met rigorous independent testing and evaluation by Underwriters Laboratories. This certification signifies that the safes meet specific safety standards, including fire resistance and burglary resistance. UL certification is widely recognized and respected in the industry, providing assurance of quality and performance.

- Other Certifications: Depending on the specific model and intended use, SureLock Security Safes may also obtain certifications from other reputable organizations. These certifications may cover aspects such as fire protection, electronic locking systems, and other safety features.

Impact on Reputation

The commitment to quality control and safety standards has a significant impact on the overall reputation of SureLock Security Safes.

- Customer Trust: By adhering to rigorous standards, SureLock Security Safes builds trust with customers. Knowing that their valuables are protected by safes that meet the highest industry benchmarks provides peace of mind.

- Industry Recognition: Certifications and adherence to safety standards contribute to the company’s reputation within the industry. SureLock Security Safes is recognized as a reliable and trustworthy manufacturer, which attracts customers seeking high-quality safes.

- Brand Loyalty: When customers experience the quality and reliability of SureLock Security Safes, they are more likely to become loyal customers. This brand loyalty can lead to repeat purchases and positive word-of-mouth recommendations, further strengthening the company’s reputation.

The Role of Innovation and Technology

At SureLock Security Safes, innovation is not just a buzzword, it’s a core value that drives every aspect of our business. We constantly strive to push the boundaries of security technology, integrating cutting-edge advancements into our safes to provide unparalleled protection and peace of mind to our customers. The integration of technology in our manufacturing process allows us to create safes that are not only robust and secure but also user-friendly and adaptable to evolving security needs.

Technological Advancements in SureLock Security Safes

The following table showcases some of the latest technological advancements implemented in SureLock Security Safes:| Technology | Description | Benefits ||—|—|—|| Biometric Locks | These locks use fingerprint, facial recognition, or iris scanning technology to grant access, providing a highly secure and personalized authentication method. | Increased security, reduced risk of unauthorized access, enhanced user convenience, and elimination of the need for physical keys.

|| Smart Home Integration | Our safes can be integrated with smart home systems, allowing users to control access, monitor activity, and receive alerts remotely through their smartphones or other connected devices. | Enhanced control and monitoring capabilities, increased security, and improved user experience. || Advanced Alarm Systems | SureLock safes incorporate sophisticated alarm systems that trigger alerts in case of unauthorized access attempts, providing an extra layer of protection.

| Real-time threat detection, prompt response to security breaches, and increased peace of mind. || Remote Monitoring and Control | Certain models offer remote monitoring and control capabilities, allowing users to track the status of their safes and manage access remotely. | Increased control and visibility, enhanced security, and remote management capabilities. || Data Encryption | We employ advanced data encryption technologies to safeguard sensitive information stored within our safes, ensuring its confidentiality and integrity.

| Enhanced data security, protection against unauthorized access, and compliance with data privacy regulations. |

Benefits of Technological Innovation

These technological innovations bring a multitude of benefits to our products and end users:* Enhanced Security: Advanced locking mechanisms, biometric authentication, and sophisticated alarm systems provide unparalleled protection against unauthorized access, safeguarding valuable assets and sensitive information.

Improved User Experience

Smart home integration, user-friendly interfaces, and remote control capabilities enhance the convenience and ease of use, making it easier for users to access and manage their valuables.

Increased Reliability

The integration of high-quality materials and advanced manufacturing processes ensures the durability and longevity of our safes, providing long-term protection and peace of mind.

Adaptability to Evolving Security Needs

By continuously incorporating the latest technological advancements, we ensure that our safes remain at the forefront of security, adapting to evolving threats and security needs.

Cost-Effectiveness

While initial investments in technologically advanced safes may seem higher, they offer long-term cost savings through enhanced security, reduced risk of theft, and improved asset protection.

“At SureLock, we believe that security is an ongoing journey, not a destination. We are committed to constantly innovating and evolving our products to stay ahead of the curve and provide our customers with the most advanced and reliable security solutions available.”

Sustainability and Environmental Practices

SureLock Security Safes is committed to sustainable manufacturing practices that minimize environmental impact and promote responsible resource utilization. The company strives to balance its commitment to producing high-quality, secure safes with its responsibility to protect the environment.

Environmental Practices Implemented by SureLock Security Safes

SureLock Security Safes implements a variety of environmental practices throughout its manufacturing process. These practices are designed to reduce waste, conserve energy, and minimize the use of harmful chemicals.

- Waste Reduction: SureLock Security Safes implements a comprehensive waste management program, including recycling, composting, and reducing waste generation. This includes recycling metal scraps, wood waste, and cardboard packaging materials. The company also minimizes packaging waste by using efficient packaging designs and reusable materials.

- Energy Conservation: The company invests in energy-efficient equipment and processes, such as LED lighting, energy-saving HVAC systems, and efficient manufacturing machinery. These measures help to reduce energy consumption and greenhouse gas emissions.

- Water Conservation: SureLock Security Safes implements water-saving measures in its manufacturing processes, such as using low-flow fixtures and recycling water for cleaning purposes. These practices help to conserve water resources and reduce wastewater discharge.

- Use of Sustainable Materials: The company prioritizes the use of sustainable materials whenever possible, such as recycled steel and wood from certified sustainable forests. This helps to reduce the environmental impact of material extraction and production.

- Chemical Management: SureLock Security Safes uses environmentally friendly cleaning and manufacturing chemicals whenever possible. The company also adheres to strict chemical handling protocols to minimize the risk of spills and pollution.

Comparison of SureLock Security Safes’ Sustainability Practices with Competitors, Where are surelock security safes made

SureLock Security Safes’ commitment to sustainability is evident in its comprehensive environmental practices. Compared to some competitors, SureLock Security Safes stands out for its proactive approach to waste reduction, energy conservation, and sustainable material sourcing.

- While many competitors may implement some basic recycling programs, SureLock Security Safes goes beyond this by incorporating composting and actively seeking ways to reduce waste generation at the source.

- In terms of energy conservation, SureLock Security Safes invests in advanced technologies and systems that go beyond standard industry practices. This proactive approach helps to reduce their carbon footprint and sets them apart from competitors who may rely on less efficient methods.

- The company’s commitment to sourcing sustainable materials, such as recycled steel and certified wood, distinguishes it from competitors who may prioritize cost over environmental considerations.

Sustainable Manufacturing Practices Flowchart

The following flowchart illustrates the key sustainable manufacturing practices implemented by SureLock Security Safes:

[Flowchart Image Description: The flowchart depicts a series of interconnected steps, starting with raw material sourcing and ending with product distribution. Each step is labeled with a concise description of the sustainable practice implemented. For example, the raw material sourcing step highlights the use of recycled steel and certified wood. The manufacturing process step showcases energy conservation through efficient machinery and LED lighting. The waste management step emphasizes recycling, composting, and waste reduction. Finally, the product distribution step focuses on using reusable and recyclable packaging materials.]

So, next time you lay your eyes on a SureLock Security Safe, remember the journey it took to get there. From the careful selection of materials to the meticulous manufacturing process, each step reflects a dedication to security and reliability. It’s a testament to the power of innovation and technology, ensuring your valuables are protected by a safe that’s not just strong, but also environmentally responsible.

The next time you need a safe, you’ll know where to turn.

Clarifying Questions

What makes SureLock Security Safes stand out from other brands?

SureLock prioritizes innovation, employing cutting-edge technology and rigorous quality control measures. They also focus on sustainability, using eco-friendly materials and manufacturing practices. This commitment to quality, security, and sustainability sets them apart in the industry.

Are SureLock Security Safes available in different sizes and styles?

Absolutely! SureLock offers a wide range of sizes and styles to cater to different needs. Whether you’re securing a small collection of valuables or a large family heirloom, there’s a SureLock safe that fits your requirements.

How can I ensure my SureLock Security Safe is properly installed?

SureLock provides installation guides and resources to help you install your safe correctly. They also recommend professional installation for optimal security and peace of mind.