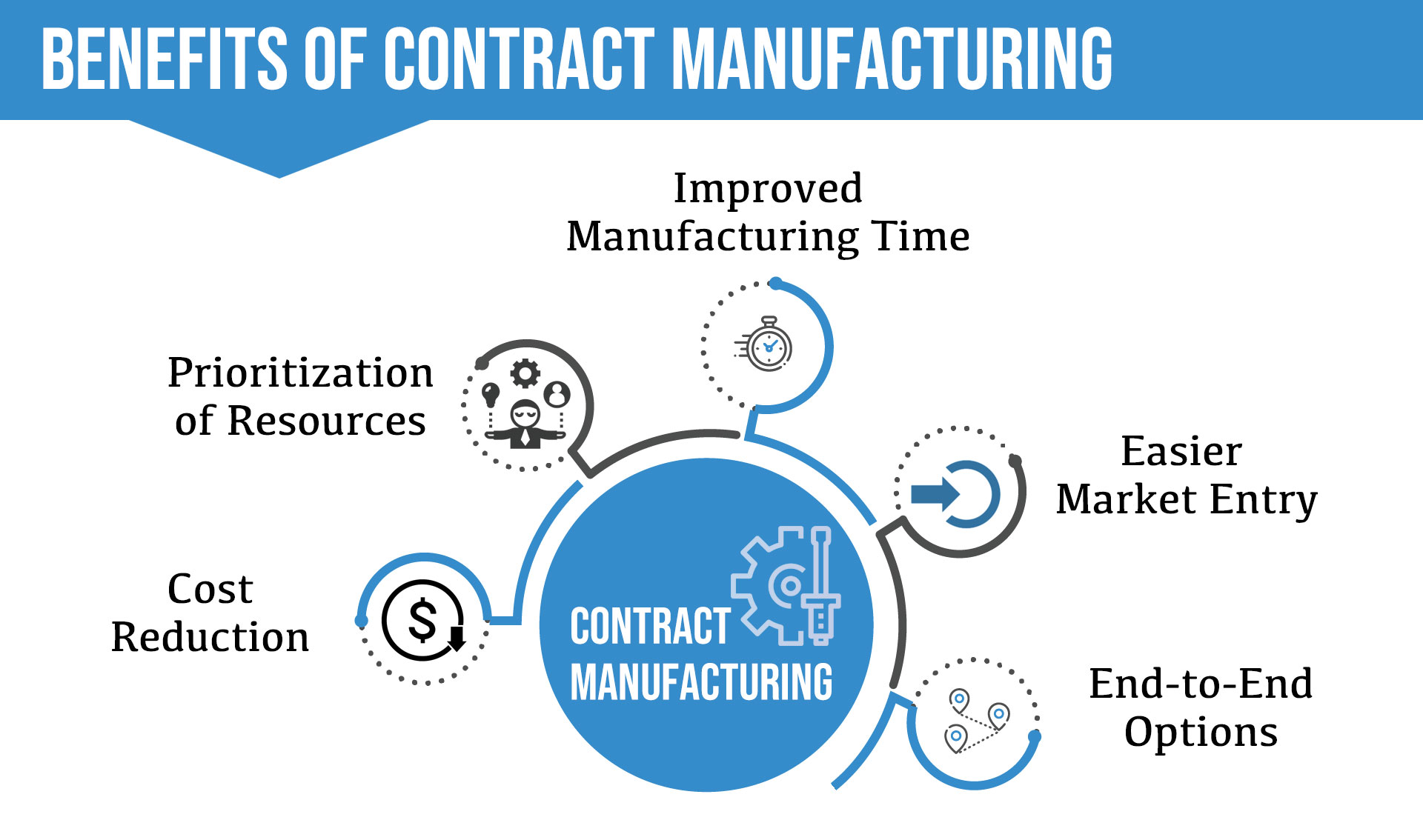

How much does contract manufacturing cost? This crucial question plagues businesses considering outsourcing production. The answer, however, isn’t a simple number; it’s a complex equation influenced by numerous factors. From product intricacy and production scale to material choices and geographic location, understanding these variables is key to securing cost-effective manufacturing partnerships. This deep dive explores the multifaceted world of contract manufacturing costs, providing insights to navigate this critical business decision.

This analysis delves into the various components of a contract manufacturing quote, including pricing models, hidden costs, and negotiation strategies. We’ll examine how different manufacturing processes, material sourcing, and geographical locations impact the bottom line. Furthermore, we’ll explore effective cost-saving measures, including product design optimization, material sourcing strategies, and the advantages and disadvantages of nearshoring versus offshoring. Case studies and industry-specific examples will illuminate the path to securing the most favorable contract manufacturing agreements.

Factors Influencing Contract Manufacturing Costs

Contract manufacturing costs are rarely straightforward. A multitude of factors intertwine to determine the final price, making careful consideration and thorough negotiation crucial for businesses seeking to outsource their production. Understanding these factors allows for more accurate budgeting and informed decision-making.

Product Complexity

Product complexity significantly impacts manufacturing costs. A simple product with few components and straightforward assembly processes will naturally be cheaper to produce than a complex device requiring specialized tooling, precise assembly techniques, and rigorous quality control measures. For instance, manufacturing a simple plastic toy involves less intricate tooling and labor than assembling a sophisticated electronic device with numerous interconnected parts and delicate circuitry.

Increased complexity translates to higher tooling costs, longer production times, and a greater risk of defects, all contributing to a higher overall price.

Production Volume

Production volume exerts a substantial influence on per-unit cost. Economies of scale dictate that higher production volumes generally lead to lower per-unit costs. This is because fixed costs, such as tooling and setup expenses, are spread across a larger number of units. Conversely, low-volume production runs result in higher per-unit costs as these fixed costs are allocated over fewer units.

For example, producing 10,000 units of a product will have a significantly lower per-unit cost than producing only 100 units, even if the production process remains the same.

Manufacturing Process Selection, How much does contract manufacturing cost

Different manufacturing processes have varying cost structures. Injection molding, a high-volume process ideal for mass production of identical plastic parts, offers lower per-unit costs for large orders due to its efficiency. Conversely, 3D printing, while offering design flexibility and prototyping advantages, typically has higher per-unit costs, especially for large-scale production, due to slower production speeds and higher material consumption per unit.

The choice of process must align with the product’s design, required volume, and desired cost-effectiveness.

Material Costs

Material costs are a major component of contract manufacturing expenses. The type of material and its sourcing significantly influence the overall cost. Using high-grade materials like specialized alloys or advanced polymers will naturally increase costs compared to using readily available, less expensive alternatives. Furthermore, sourcing materials from geographically distant locations or from suppliers with limited capacity can drive up costs due to transportation and potential supply chain disruptions.

For example, sourcing rare earth minerals for electronics manufacturing will be far more expensive than using common plastics.

Hidden Costs

Several hidden costs often escape attention during initial contract negotiations. These can include tooling costs beyond initial setup, quality control and testing expenses, packaging and labeling charges, transportation and logistics fees, and potential customs duties and tariffs. Thorough contract review and a clear understanding of all included and excluded services are crucial to avoid unexpected expenses. For instance, a seemingly low per-unit price might not account for the costs of specialized testing equipment or intricate packaging requirements.

Geographical Location

Geographical location impacts labor and overhead costs significantly. Manufacturing in countries with lower labor costs, such as certain regions in Asia, will generally lead to lower production expenses compared to manufacturing in countries with higher labor costs, such as the United States or Western Europe. However, this must be weighed against factors like transportation costs, potential trade barriers, and the quality and reliability of local suppliers.

Overhead costs, such as rent, utilities, and taxes, also vary significantly across different geographical locations.

Contract Manufacturing Models: Cost Comparison

| Contract Manufacturing Model | Tooling Costs | Labor Costs | Overhead Costs |

|---|---|---|---|

| Full-Service | Typically included | Generally higher due to comprehensive services | Higher due to broader scope of services |

| Partial-Service | May be shared or client-provided | Lower due to limited service scope | Lower due to narrower service scope |

| Modular Manufacturing | Can be modularized and optimized | Can be optimized by assigning specific tasks to specialized manufacturers | Can be optimized through efficient resource allocation across different manufacturers |

| Just-in-Time (JIT) | Optimized through efficient inventory management | Potential for reduced labor costs through streamlined processes | Reduced overhead costs due to minimized inventory and storage needs |

Understanding Contract Manufacturing Quotes

Contract manufacturing quotes are the cornerstone of any successful outsourcing partnership. A thorough understanding of their components, pricing models, and negotiation strategies is crucial for securing favorable terms and ensuring project success. Misinterpretations or omissions can lead to significant cost overruns and project delays. This section delves into the intricacies of contract manufacturing quotes, empowering businesses to navigate this critical stage effectively.

Typical Components of a Contract Manufacturing Quote

A comprehensive contract manufacturing quote typically includes several key elements. These elements provide a transparent breakdown of all anticipated costs, enabling clients to make informed decisions. Missing components or vague descriptions can indicate a less-than-professional approach from the manufacturer.

- Unit Cost: This represents the cost per manufactured unit, encompassing materials, labor, and overhead. It’s often the most significant component.

- Setup Costs: These are one-time costs associated with preparing the manufacturing line for production, including tooling, programming, and initial setup runs.

- Materials Costs: A detailed breakdown of raw materials and components, including quantities and unit prices. This section should specify the source and quality of materials used.

- Labor Costs: The cost of direct labor involved in manufacturing, including wages, benefits, and potential overtime.

- Overhead Costs: Indirect costs associated with manufacturing, such as facility rent, utilities, and administrative expenses. These are often expressed as a percentage of direct labor or materials costs.

- Quality Control Costs: Expenses related to testing, inspection, and quality assurance processes throughout the manufacturing cycle.

- Packaging and Shipping Costs: The cost of packaging the finished goods and transporting them to the client’s designated location. This includes packaging materials, freight, and insurance.

- Engineering and Design Costs (if applicable): Costs associated with any design or engineering work performed by the manufacturer, such as tooling design or product modifications.

Common Pricing Models in Contract Manufacturing

Manufacturers typically employ different pricing models, each with its own advantages and disadvantages. Choosing the right model depends on the project’s complexity, volume, and duration.

- Per-Unit Pricing: A fixed cost per unit produced. This model is straightforward and easy to understand, particularly for high-volume, standardized products. However, it may not be suitable for projects with significant upfront setup costs or fluctuating production volumes.

- Fixed-Price Pricing: A total fixed price for a defined quantity of products. This model provides cost certainty for the client but requires a precise scope definition. Changes to the scope may necessitate renegotiation.

- Time and Materials Pricing: The manufacturer charges for the time spent and materials used. This model offers flexibility for projects with evolving requirements but lacks upfront cost certainty. Careful tracking of time and materials is crucial to avoid cost overruns.

Sample Contract Manufacturing Quote

| Item | Description | Quantity | Unit Cost | Total Cost |

|---|---|---|---|---|

| Setup Costs | Tooling and initial setup | 1 | $5,000 | $5,000 |

| Materials | Raw materials and components | 1000 | $10 | $10,000 |

| Labor | Direct labor costs | 1000 | $5 | $5,000 |

| Overhead | 15% of labor costs | $750 | ||

| Quality Control | Testing and inspection | $1,000 | ||

| Packaging & Shipping | Packaging and freight | $2,000 | ||

| Total | $23,750 |

Negotiating Favorable Pricing Terms

Negotiating a contract manufacturing quote requires a strategic approach. This involves understanding the market, the manufacturer’s cost structure, and leveraging your leverage points.

- Volume Discounts: Negotiate larger order quantities to secure lower per-unit costs.

- Payment Terms: Discuss favorable payment schedules, potentially including milestones or progress payments.

- Material Sourcing: Explore options for providing some materials to reduce the manufacturer’s costs.

- Alternative Manufacturing Processes: Discuss potentially more cost-effective manufacturing processes.

- Competitive Bidding: Obtain quotes from multiple manufacturers to compare pricing and terms.

Clarifying Payment Schedules and Milestones

Clearly defined payment schedules and milestones are critical for mitigating risk and ensuring project success. Ambiguity can lead to disputes and delays.

The contract should specify payment terms, including down payments, progress payments tied to specific milestones (e.g., completion of tooling, initial production run, final delivery), and final payment upon acceptance of the finished goods. Penalties for late delivery or failure to meet quality standards should also be clearly Artikeld. A well-defined payment schedule fosters trust and transparency between the client and the manufacturer.

Minimizing Contract Manufacturing Costs

Effective cost management is crucial for the success of any product relying on contract manufacturing. Minimizing these costs requires a proactive and strategic approach encompassing product design, material sourcing, and manufacturer selection. Failing to optimize these areas can significantly impact profitability and market competitiveness.

Product Design Optimization for Cost Reduction

Strategic product design plays a pivotal role in minimizing manufacturing costs. Simplifying the design, using standardized components, and incorporating design for manufacturing (DFM) principles are key strategies. For instance, reducing the number of parts needed decreases assembly time and material costs. Choosing readily available components avoids costly custom fabrication. DFM involves designing products that are easy and efficient to manufacture, considering factors like material selection, assembly methods, and tooling requirements.

A well-executed DFM process can lead to significant reductions in labor, material, and tooling costs. For example, a product originally designed with complex curves might be redesigned with simpler, straight lines, reducing machining time and material waste.

Cost-Effective Material and Component Sourcing

Sourcing materials and components strategically is another critical aspect of cost reduction. This involves exploring various suppliers, negotiating favorable pricing, and considering alternative materials with similar functionality but lower cost. Utilizing readily available materials, opting for bulk purchasing to leverage economies of scale, and implementing robust inventory management systems to minimize waste are all effective strategies. For example, switching from a premium grade steel to a less expensive but equally functional alternative can significantly reduce material costs without compromising product performance.

Negotiating long-term contracts with suppliers can also secure better pricing and ensure a reliable supply chain.

Nearshoring versus Offshoring Manufacturing

The decision between nearshoring and offshoring manufacturing significantly impacts costs. Nearshoring, manufacturing in a geographically closer location, often entails higher labor costs but lower transportation and communication expenses, shorter lead times, and better quality control. Offshoring, manufacturing in a distant location, typically offers lower labor costs but potentially higher transportation, communication, and logistical costs, along with longer lead times and increased risk of quality control issues.

The optimal choice depends on various factors including product complexity, volume, required lead times, and risk tolerance. For instance, a company producing high-volume, low-complexity products might benefit from offshoring, while a company producing high-complexity products with short lead-time requirements might opt for nearshoring.

Contract Manufacturer Comparison

Comparing different contract manufacturers based on their pricing and capabilities is essential for cost optimization. This involves requesting detailed quotes from multiple manufacturers, carefully analyzing their pricing structures, and assessing their technological capabilities, production capacity, quality control measures, and experience. A thorough comparison should consider not just the initial manufacturing cost but also potential hidden costs like tooling, transportation, and potential quality-related issues down the line.

For example, a manufacturer offering a slightly higher initial cost might prove more cost-effective in the long run due to superior quality control and reduced waste.

Checklist for Selecting a Cost-Effective Contract Manufacturer

Selecting the right contract manufacturer is crucial for minimizing costs. A comprehensive checklist should include:

Before creating the checklist, it’s important to note that the selection process requires careful consideration of multiple factors to ensure long-term cost-effectiveness. A thorough evaluation will help avoid unforeseen expenses and ensure a successful manufacturing partnership.

- Detailed cost breakdown and pricing transparency

- Technological capabilities and experience with similar products

- Production capacity and lead times

- Quality control processes and certifications

- Location and logistical considerations

- Communication and responsiveness

- Financial stability and reputation

- Intellectual property protection measures

- Flexibility and scalability

Successfully navigating the complexities of contract manufacturing costs requires a strategic approach. By carefully considering the factors Artikeld—product design, material selection, manufacturing processes, location, and negotiation—businesses can significantly reduce expenses and secure favorable agreements. Remember, proactive planning, thorough research, and a clear understanding of your needs are paramount in achieving cost-effective outsourcing. Don’t let hidden costs derail your project; empower yourself with knowledge and secure the best possible deal.

FAQ Insights: How Much Does Contract Manufacturing Cost

What are some common hidden costs in contract manufacturing?

Hidden costs can include tooling fees, transportation and logistics, quality control inspections, and potential penalties for late deliveries or quality issues.

How can I negotiate better pricing with a contract manufacturer?

Negotiate by leveraging volume discounts, exploring alternative materials, optimizing your product design for easier manufacturing, and comparing quotes from multiple manufacturers.

What is the difference between full-service and partial-service contract manufacturing?

Full-service handles the entire process, from design to delivery. Partial-service handles only specific aspects, like assembly or packaging.

Can I get a guaranteed price upfront?

While a fixed price is possible for simpler projects with defined scopes, more complex projects often use time and materials pricing or per-unit pricing with potential adjustments.