How much does contract manufacturing cost? This seemingly simple question unravels into a complex web of factors that can dramatically inflate – or deflate – your final price tag. The cost isn’t simply a matter of adding up materials and labor; it’s a negotiation, a gamble, and a reflection of global economic forces. Understanding these forces is crucial for businesses hoping to navigate the treacherous waters of outsourcing production, avoiding costly pitfalls and securing favorable terms.

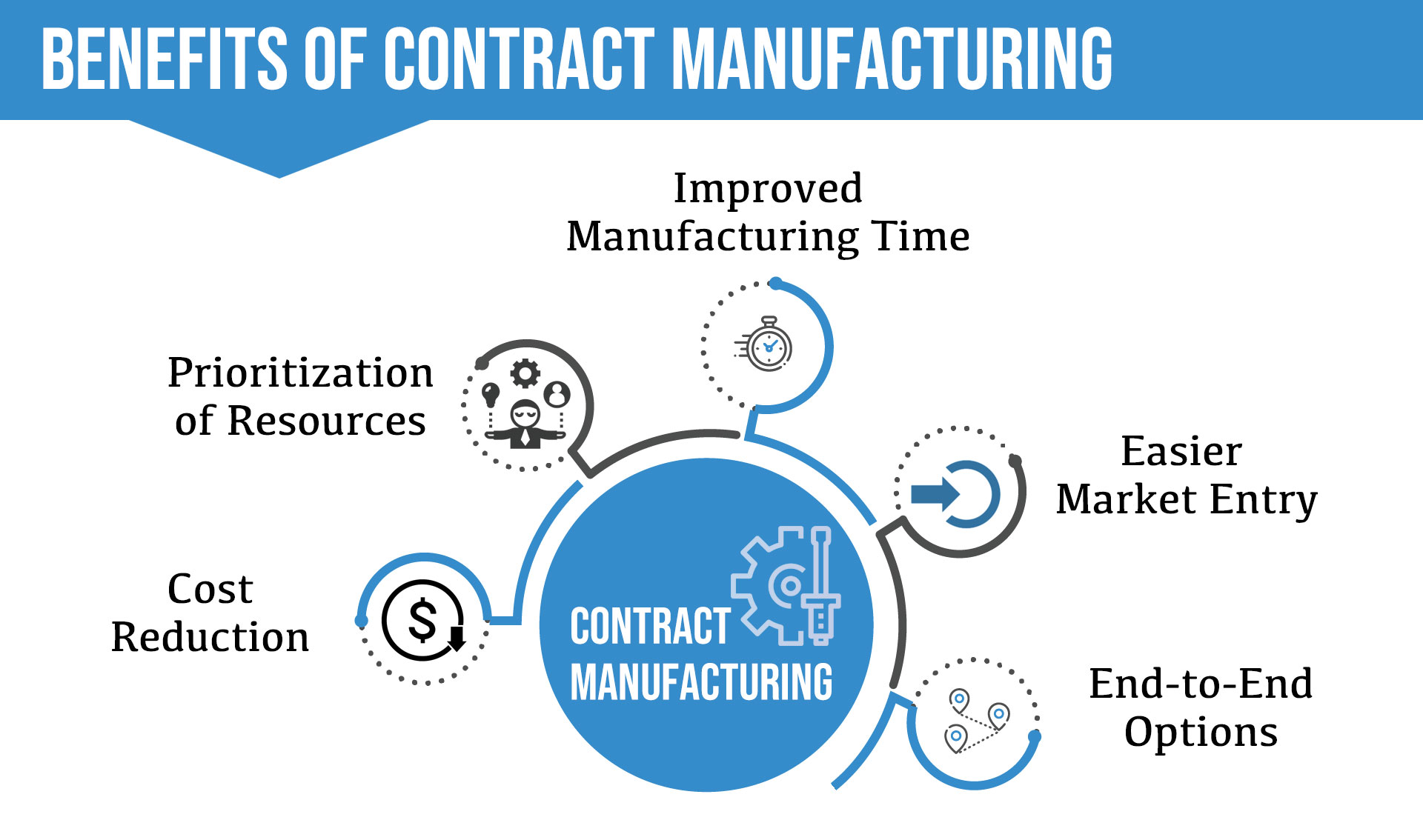

This analysis dissects the key drivers of contract manufacturing costs, exposing the hidden expenses and leveraging strategies for successful negotiation. We’ll examine regional disparities, contract structures, and the often-overlooked influence of unforeseen circumstances. Ultimately, our goal is to equip you with the knowledge to make informed decisions and protect your bottom line.

Hidden Costs and Unexpected Expenses: How Much Does Contract Manufacturing Cost

Yo, peeps! So you’re thinking about contract manufacturing, eh? Sounds rad, right? But hold up, there’s more to it than just the initial quote. We’re diving deep into the hidden costs that can totally ambush your budget if you’re not careful. Think of it as navigating the murky waters of Pontianak’s backstreets – you gotta be street-smart to avoid getting lost (or broke!).

Potential Hidden Costs

Let’s get real. Sometimes, the biggest surprises aren’t what you see upfront. Ignoring these hidden costs can lead to major budget overruns, leaving you scrambling like a monkey trying to catch a falling durian. Here are five sneaky culprits to watch out for:

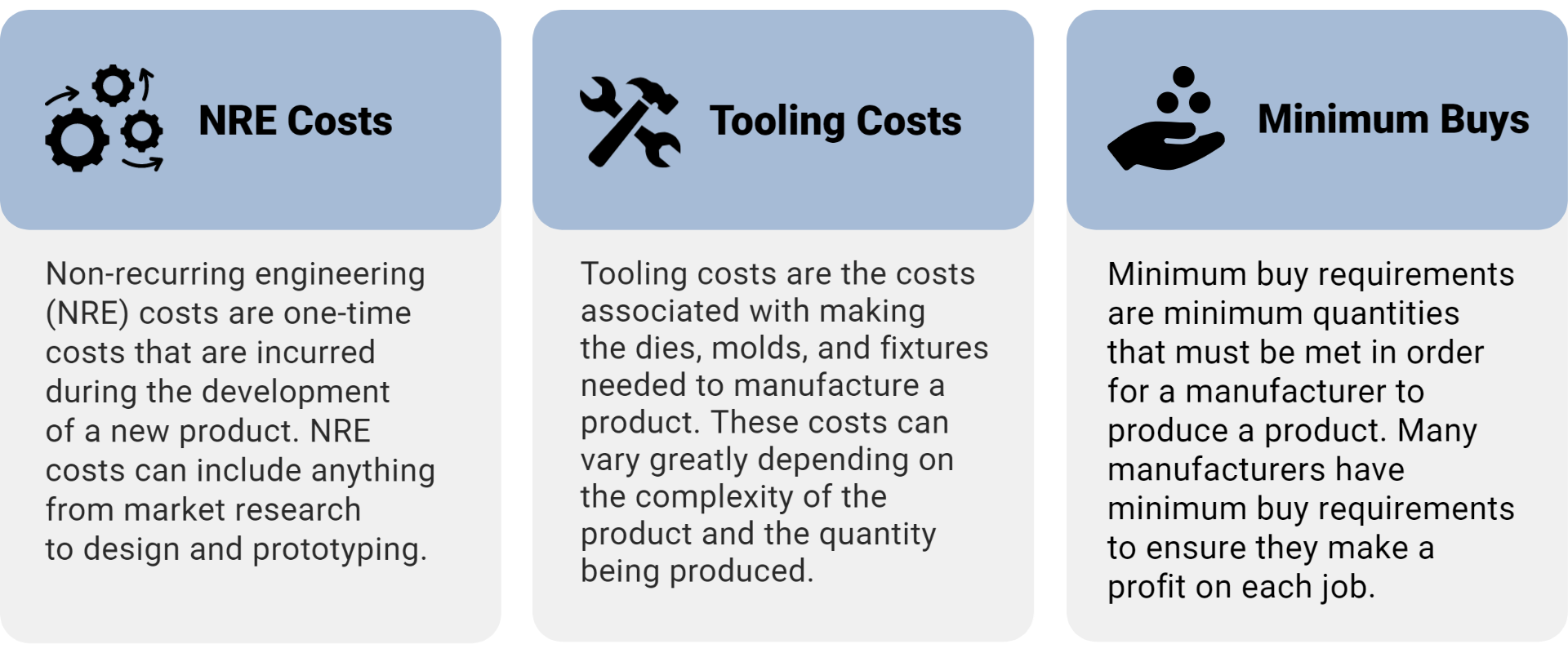

- Tooling Costs: This isn’t just about the initial investment in molds or dies; it’s also about maintenance, repairs, and potential replacements down the line. Think of it like owning a classic car – the initial purchase is one thing, but upkeep can be a beast.

- Shipping and Logistics: Don’t underestimate the cost of getting your goods from the factory to your warehouse. This includes transportation, insurance, customs duties, and potential storage fees. Imagine the logistical nightmare of shipping a container of delicate handcrafted pottery across the globe!

- Unexpected Material Price Fluctuations: Raw material costs can fluctuate wildly due to market forces. A sudden spike in the price of your primary material can seriously impact your profit margins. Think of it like the price of chili – sometimes it’s cheap, sometimes it’s ridiculously expensive.

- Quality Control and Rework: Defective products are a real pain. The costs associated with identifying, rectifying, or discarding faulty goods can quickly eat into your profits. Picture a whole batch of kue lapis with uneven layers – the cost of remaking it all is substantial.

- Contract Negotiation and Legal Fees: Getting a solid contract is crucial. You might need legal assistance to review the contract, negotiate favorable terms, and resolve any disputes that arise. This can add unexpected costs, but it’s an investment in protecting your interests.

The Importance of Contract Review

Dude, seriously. Don’t just skim the contract. Get a lawyer (or at least a really detail-oriented friend) to pore over every clause. A well-negotiated contract can protect you from unforeseen expenses and liabilities. Think of it as your legal shield against those sneaky hidden costs.

Ignoring this step is like walking through a jungle without a machete – you’re asking for trouble.

Tooling Costs and Their Impact

Tooling costs are a significant upfront investment. It’s essential to factor in not only the initial cost but also the potential for future repairs, replacements, and even obsolescence. This is a long-term commitment, so careful planning and budgeting are crucial. It’s like investing in a high-quality wok – the initial cost might be high, but it’ll last you a long time and make your cooking way better.

Quality Control Issues and Costs

Quality control is paramount. Defects can lead to recalls, customer dissatisfaction, and significant financial losses. Think about the cost of recalling a batch of faulty products, the reputational damage, and the lost sales. It’s way cheaper to get it right the first time.

Strategies for Mitigating Hidden Costs

Alright, so how do you avoid getting totally blindsided? Here’s the lowdown on minimizing those unexpected expenses:

- Thorough Due Diligence: Research your contract manufacturer thoroughly. Check their reputation, track record, and financial stability.

- Detailed Contract Negotiation: Negotiate clear and specific terms regarding pricing, timelines, quality control, and liability.

- Regular Communication: Maintain open and consistent communication with your manufacturer to address any potential issues early on.

- Contingency Planning: Build a buffer into your budget to account for unexpected expenses or material price fluctuations.

- Robust Quality Control Procedures: Implement rigorous quality control measures at each stage of the manufacturing process.

Negotiating and Managing Contract Manufacturing Costs

Yo, Pontianak peeps! So you’ve figured out the basics of contract manufacturing costs, including those sneaky hidden ones. Now let’s get down to the brass tacks – negotiating those prices and keeping everything under control. Think of it like haggling at the Pasar Tengah, but with a bit more finesse and a whole lot more spreadsheets.Effective Strategies for Negotiating Favorable PricingGetting the best deal with contract manufacturers isn’t about shouting the loudest; it’s about being smart and prepared.

First, know your worth – what’s the market rate for similar products? Then, present a solid business case, showing them the potential volume and long-term partnership opportunities. Don’t be afraid to shop around; multiple quotes give you leverage. Remember, friendly competition is good competition. Think of it as a friendly game of dama, where you want to make the best moves to win.

A strong relationship built on mutual respect and transparency is key. Don’t be afraid to negotiate payment terms, too – longer payment cycles can sometimes offer savings. Lastly, always get everything in writing.Clear Communication and DocumentationCommunication is everything, especially when dealing with multiple parties and complex processes. Clear contracts, detailed specifications, and regular progress reports are non-negotiable.

Think of it as building a rumah gadang – you need a solid foundation and detailed blueprints. Ambiguity is your enemy; clear communication prevents misunderstandings and costly rework. Document everything, from initial discussions to final payments, to protect yourself and maintain a clear audit trail. Use a shared platform for easy access and updates, so everyone’s on the same page.The Role of Supplier Relationship Management in Controlling CostsBuilding strong relationships with your contract manufacturers is like cultivating a fruitful durian orchard.

It takes time and effort, but the rewards are significant. Regular communication, proactive problem-solving, and mutual respect foster trust and collaboration. This leads to better pricing, faster turnaround times, and improved quality. Consider implementing a formal supplier relationship management (SRM) system to track performance, identify areas for improvement, and ensure consistent quality.Analyzing Quotes and Proposals to Identify Potential Cost SavingsDon’t just look at the bottom line.

Dive deep into the details of each quote. Compare unit costs, material costs, labor costs, and overhead charges. Are there any discrepancies? Are there opportunities for consolidation or simplification? Can you negotiate volume discounts?

Analyzing quotes meticulously is like meticulously examining a piece of batik; every detail matters. A detailed comparison will reveal areas for potential cost savings. Remember, even small savings can add up significantly over time.Developing a Detailed Budget and Cost Control PlanBefore you even start negotiating, create a detailed budget that accounts for all potential costs. Include raw materials, labor, shipping, quality control, and any other relevant expenses.

Regularly monitor your spending against your budget, and adjust as needed. This proactive approach helps you stay on track and avoid costly surprises. Think of it as managing your warung – you need to keep a close eye on your expenses to ensure profitability. Regular reviews and adjustments are crucial to maintain control.

Illustrative Examples of Contract Manufacturing Costs

Okay, so you wanna know about the real nitty-gritty of contract manufacturing costs, eh? Let’s ditch the jargon and get down to brass tacks with some concrete examples. Think of it like choosing your

nasi lemak* – you gotta know the price before you order, right?

We’ll look at three different scenarios, each with a different product, production volume, and resulting cost structure. This will give you a clearer picture of how things can vary wildly depending on your needs. Remember, these are estimates – your actual costs might differ based on specific negotiations and unforeseen circumstances. Always get that

-harga pastian* (confirmed price) in writing!

Scenario 1: Simple Wooden Toys

Imagine you’re making a simple wooden toy, like a rocking horse. The design is straightforward, the materials are readily available (basic wood, paint, screws), and the manufacturing process involves basic carpentry and assembly. Let’s say you need 1000 units.

Manufacturing Process: Cutting, shaping, sanding, painting, assembly. This requires relatively unskilled labor, simple machinery (saws, drills, paint sprayers), and a small factory space.

Estimated Costs:

Materials: $5/unit

Labor: $3/unit

Overhead (rent, utilities, machinery maintenance): $2/unit

Total Cost per Unit: $10

Total Project Cost: $10,000

Scenario 2: Custom-Designed Electronics, How much does contract manufacturing cost

Now, let’s bump it up a notch. Say you’re producing a custom-designed smart home device – think a sophisticated smart speaker with unique features. This requires more complex components (microchips, sensors, speakers), advanced manufacturing processes, and skilled labor. We’re talking about a run of 500 units this time.

Manufacturing Process: PCB assembly, component soldering, software programming, quality testing. This requires skilled technicians, specialized machinery (SMT machines, testing equipment), and a higher level of quality control.

Estimated Costs:

Materials: $50/unit (complex components drive up costs)

Labor: $20/unit (skilled labor is expensive)

Overhead: $15/unit (specialized equipment and facilities)

Total Cost per Unit: $85

Total Project Cost: $42,500

Scenario 3: High-Volume Apparel Production

Finally, let’s consider a large-scale apparel production run. You’re manufacturing 10,000 basic t-shirts with a simple design. While the individual product is simple, the sheer volume changes the game.

Manufacturing Process: Fabric cutting, sewing, printing (screen printing or embroidery), quality inspection. This requires high-speed sewing machines, efficient production lines, and potentially a larger workforce.

Estimated Costs:

Materials: $5/unit (fabric, thread, ink)

Labor: $2/unit (high volume allows for lower labor cost per unit)

Overhead: $1/unit (spread across a large production run)

Total Cost per Unit: $8

Total Project Cost: $80,000

Cost Comparison Table

| Scenario | Product | Volume | Total Cost |

|---|---|---|---|

| 1 | Simple Wooden Toy | 1000 | $10,000 |

| 2 | Custom Smart Speaker | 500 | $42,500 |

| 3 | Basic T-shirts | 10,000 | $80,000 |

As you can see, the costs vary significantly. Scenario 2, with its complex product and specialized requirements, is the most expensive per unit. Scenario 3, despite the high total cost, has the lowest cost per unit due to economies of scale. Remember, these are just examples – your own project will have its own unique cost structure.

So,

-jangan lupa* (don’t forget) to do your homework before you sign on the dotted line!

Successfully navigating the complexities of contract manufacturing requires a keen awareness of the myriad factors influencing cost. From geographical location and contract type to hidden expenses and negotiation strategies, each element plays a critical role in determining the final price. By meticulously analyzing these factors and employing proactive cost-control measures, businesses can mitigate risks, secure favorable terms, and achieve a competitive advantage in the global marketplace.

Remember, informed decision-making is the cornerstone of effective cost management in contract manufacturing.

Expert Answers

What are some common contract manufacturing scams to watch out for?

Beware of unusually low bids that seem too good to be true. Thoroughly vet potential manufacturers, checking for verifiable references and financial stability. Scrutinize contracts carefully, paying close attention to clauses related to liability, intellectual property, and dispute resolution.

How can I estimate contract manufacturing costs before engaging a manufacturer?

Use online cost calculators (with caution, as accuracy varies), conduct thorough market research to understand typical pricing for similar products, and request detailed quotes from multiple manufacturers. Compare these quotes meticulously, considering all factors discussed in this analysis.

What is the typical lead time for contract manufacturing?

Lead times vary significantly based on product complexity, order volume, and the manufacturer’s capacity. Expect longer lead times for complex products and large orders. Always clarify lead times upfront and factor them into your overall project timeline.

What happens if the contract manufacturer experiences production delays?

Contracts should Artikel clear procedures for handling delays, including potential penalties for the manufacturer. Thoroughly review these clauses before signing any agreement. Maintain open communication with the manufacturer to proactively address any potential issues.