A rubber stamp creates what type of print? The seemingly simple question unveils a world of fascinating detail. From the humble self-inking stamp adorning envelopes to the intricate designs used in fine art, the print a rubber stamp produces is far more nuanced than meets the eye. The type of rubber, the ink’s composition, even the pressure applied – all contribute to the final impression, a testament to the enduring power of this seemingly simple tool.

We’ll delve into the fascinating interplay of materials, techniques, and results, revealing the secrets behind the seemingly ordinary rubber stamp print.

This exploration will cover various stamp types – self-inking, pre-inked, and hand-stamped – comparing their print quality, durability, and the unique characteristics of the impressions they leave behind. We’ll examine different ink types, their properties, and how they affect the print’s clarity, sharpness, and longevity. The influence of factors like stamp condition, surface texture, and even environmental conditions on print quality will also be discussed, providing a comprehensive understanding of this often-overlooked yet vital printing method.

Types of Rubber Stamps and Their Prints: A Rubber Stamp Creates What Type Of Print

Get ready to dive into the fascinating world of rubber stamps! From the humble self-inking stamp to the more robust pre-inked variety, these versatile tools offer a surprising range of print quality and durability. We’ll explore the different types, the materials used, and how these factors influence the final impression. Prepare to be amazed by the possibilities!

The type of rubber stamp you choose significantly impacts the print it produces. This is influenced not only by the stamp’s construction but also the ink used and the design itself. Let’s explore the key differences.

Self-Inking Rubber Stamps

Self-inking stamps are incredibly convenient. They contain an integrated ink pad, eliminating the need for separate inking. This makes them ideal for frequent use and quick stamping. The print quality is generally good, offering crisp, clear impressions, especially with high-quality inks. However, the ink pad has a limited lifespan and will eventually need replacing.

The size of the self-inking mechanism limits the overall stamp size, generally keeping them smaller than other types.

Pre-Inked Rubber Stamps, A rubber stamp creates what type of print

Pre-inked stamps offer a significant advantage in terms of print longevity. They utilize a replaceable ink cartridge, providing thousands of impressions before needing a refill. This makes them a cost-effective solution for high-volume stamping needs. Print quality is comparable to self-inking stamps, producing sharp, consistent images. The larger cartridge size allows for a wider variety of stamp sizes compared to self-inking stamps.

Hand-Stamped Rubber Stamps

Hand-stamped rubber stamps require manual inking with an ink pad. This gives you the greatest control over ink application, allowing for specialized effects. However, it’s a more time-consuming process and requires consistent technique to ensure uniform prints. The print quality depends heavily on the user’s skill and the quality of the ink and pad used. This method is often chosen for more artistic applications or when working with specialized inks.

Rubber Stamp Materials and Ink Types

The material of the stamp itself and the type of ink used greatly affect print quality and durability. Rubber stamps, while traditional, can be less durable than polymer stamps, which are more resistant to wear and tear. Oil-based inks generally offer superior durability and vibrancy compared to water-based inks, but water-based inks are better for certain applications, such as porous surfaces.

Stamp Size and Design’s Influence on Prints

The size of the rubber stamp directly impacts the size of the print. Larger stamps are ideal for bold statements or logos, while smaller stamps are suitable for details or discreet markings. The design itself also plays a crucial role; intricate designs require higher-quality materials and inks to ensure sharp detail reproduction. A poorly designed stamp, regardless of its type, will produce a poor-quality print.

Comparison of Rubber Stamp Print Characteristics

| Type | Ink Type | Print Quality | Durability |

|---|---|---|---|

| Self-inking | Oil-based (typically) | Good, crisp impressions | Moderate; ink pad lifespan limits total impressions |

| Pre-inked | Oil-based or water-based | Excellent, consistent impressions | High; replaceable ink cartridge allows for thousands of impressions |

| Hand-stamped | Oil-based or water-based | Variable; depends on user skill and ink quality | High; stamp itself is durable, but ink application affects print longevity |

Ink and Print Characteristics

The magic of a rubber stamp lies not just in the carved design, but also in the ink that brings it to life! The type of ink you choose dramatically affects the final print’s appearance, longevity, and overall quality. Let’s delve into the fascinating world of stamp inks and their impact on your prints.

Different ink formulations offer unique properties, influencing everything from the vibrancy of the color to how well the image resists smudging. Understanding these characteristics is key to achieving the perfect stamped impression every time.

Oil-Based Inks

Oil-based inks are known for their rich, deep colors and excellent archival qualities. The oil base provides a robust, long-lasting print that resists fading and smudging. However, they tend to have a longer drying time than water-based inks and require a more thorough cleaning process. Their high pigment concentration contributes to vibrant, saturated prints, ideal for applications where longevity and impact are paramount, such as official documents or archival stamping.

Water-Based Inks

Water-based inks offer a fast-drying solution, making them ideal for high-volume stamping. They are generally considered more environmentally friendly than oil-based inks due to their lower toxicity and easier cleanup. While not as vibrant or long-lasting as oil-based inks, they still produce clear, legible prints suitable for many applications. The lower viscosity often leads to sharper, more defined prints compared to thicker oil-based inks, especially with intricate designs.

Pigment-Based Inks

Pigment-based inks are formulated with finely ground pigments suspended in a liquid carrier, typically water-based. These inks offer excellent colorfastness and resistance to fading, making them suitable for applications where color retention is crucial. The pigment particles contribute to a more opaque and vibrant print compared to dye-based inks. However, the thicker consistency might result in slightly less sharp lines, especially with fine details.

Ink Viscosity and Print Clarity

Ink viscosity, or thickness, plays a crucial role in print clarity and sharpness. Thicker inks (like some pigment-based inks) can lead to slightly blurred edges and less defined details, particularly in intricate designs. Thinner inks (like some water-based inks) tend to produce sharper, more crisp prints. Finding the right viscosity for your stamp and application is essential for optimal results.

For example, a thin, low-viscosity ink might be ideal for detailed logos, while a thicker ink might be better suited for a bold, impactful stamp.

Ink Color and Saturation and Their Influence on Print Appearance

The color and saturation of the ink directly impact the final print’s visual appeal. A highly saturated ink will produce a bold, vibrant print, while a less saturated ink will result in a paler, more subdued impression. The choice of color is often dictated by the intended use and branding considerations. For instance, a bright red ink might be used for promotional materials, while a more muted blue might be preferred for official documentation.

Furthermore, the background color of the stamped surface can also influence the perceived color and saturation of the print. A dark background might make lighter ink colors appear duller, while a light background can enhance the vibrancy.

Ink Type and Print Properties

| Ink Type | Smudging | Drying Time | Colorfastness |

|---|---|---|---|

| Oil-Based | Low | High | High |

| Water-Based | Medium | Low | Medium |

| Pigment-Based | Low | Medium | High |

Factors Affecting Print Quality

Getting a crisp, clear impression from your rubber stamp isn’t just about the stamp itself; it’s a delicate dance of several factors working in harmony. From the pressure you apply to the humidity in the air, many elements can influence the final print quality. Understanding these factors allows you to troubleshoot issues and achieve consistently excellent results. Let’s delve into the details!

The evenness of ink distribution is paramount for a professional-looking stamp. A patchy or uneven print detracts from its impact. Several key factors contribute to this crucial aspect of print quality.

Ink Distribution and Stamp Condition

Pressure applied during stamping significantly impacts ink distribution. Too little pressure results in a faint, incomplete impression, while excessive pressure can cause the ink to smear or the stamp to distort. The ideal pressure is firm but gentle, ensuring complete contact between the inked stamp and the surface. The condition of the stamp itself also plays a vital role.

A worn or damaged stamp, with cracks or uneven surfaces, will lead to inconsistent ink transfer. Regular cleaning and proper storage are essential to maintain optimal stamp condition and prevent premature wear. A well-maintained stamp, with its ink pad properly inked, will deliver consistently even prints.

Surface Texture’s Influence on Print Clarity

The texture of the material being stamped directly influences print clarity. Smooth surfaces, such as glossy paper or card stock, generally yield the sharpest, most defined prints. Conversely, rough or textured surfaces, like fabric or heavily embossed paper, can cause the ink to bleed or the print to appear blurry. The ink may also become unevenly absorbed by the fibers of the material, resulting in a less crisp impression.

For example, trying to stamp a logo onto a coarse woven fabric will produce a significantly less sharp result than stamping the same logo onto a smooth, coated paper.

Environmental Impact on Print Quality

Environmental conditions such as temperature and humidity can surprisingly affect print quality. High temperatures can cause the ink to dry too quickly, leading to uneven application and potentially causing the ink to crack. Conversely, low temperatures can thicken the ink, making it difficult to transfer evenly onto the surface. High humidity can lead to ink bleeding or smearing, while low humidity might result in the ink drying too quickly, making it difficult to achieve a complete and sharp impression.

For optimal results, it’s advisable to work in a moderate temperature and humidity environment.

Several common problems can plague rubber stamp prints, but thankfully, solutions exist for each.

- Problem: Faint or incomplete prints. Solution: Increase stamping pressure, ensure the ink pad is properly inked, and check for damage to the stamp.

- Problem: Smeared or blurry prints. Solution: Reduce stamping pressure, allow the ink to dry slightly before handling, and use a suitable ink for the surface material.

- Problem: Uneven ink distribution. Solution: Clean the stamp thoroughly, ensure even ink coverage on the pad, and check for any damage to the stamp surface.

- Problem: Ink cracking or drying too quickly. Solution: Use a slower-drying ink, work in a cooler environment, and avoid excessive pressure.

- Problem: Ink bleeding into the stamped material. Solution: Choose an ink designed for the specific surface material, reduce pressure, and consider using a less absorbent material.

Applications and Print Examples

Rubber stamps, those unassuming little blocks of inked power, have a surprisingly vast range of applications, leaving their unique mark across countless industries and creative endeavors. From the mundane to the magnificent, the versatility of rubber stamps is truly remarkable. Their ability to produce crisp, clear impressions or subtly textured marks allows for a wide spectrum of uses, making them an indispensable tool in many fields.

The type of print a rubber stamp produces depends heavily on the stamp itself – its design, the material it’s made from, and the ink used – as well as the surface it’s applied to. A simple self-inking stamp might create a clean, bold impression on a crisp piece of paper, while a more intricate, hand-carved stamp might produce a subtly textured image on fabric or even a piece of pottery.

Let’s delve into some specific examples.

Examples of Rubber Stamp Prints

Here, we’ll explore three distinct rubber stamp print examples, each showcasing unique characteristics and material applications.

Example 1: The Corporate Seal. Imagine a large, circular stamp, perhaps made of high-quality vulcanized rubber, featuring an intricately detailed company logo and a border of decorative flourishes. This seal is used for official documents, contracts, and important correspondence. The ink used is typically a rich, dark blue or black, creating a sharp, highly legible impression with consistent color intensity. The print itself exudes professionalism and authority, immediately signifying the document’s legitimacy.

Example 2: The Personalized Stationery Stamp. This example is a smaller, rectangular stamp, possibly made from photopolymer, with a simple, elegant design – perhaps just a name and address. It’s used for personal correspondence, adding a touch of individuality to letters and postcards. The ink used might be a vibrant color, complementing the stationery’s design. The print is crisp and clear, offering a clean, professional aesthetic.

The stamp might even use a special ink, like metallic gold or silver, for a more luxurious feel.

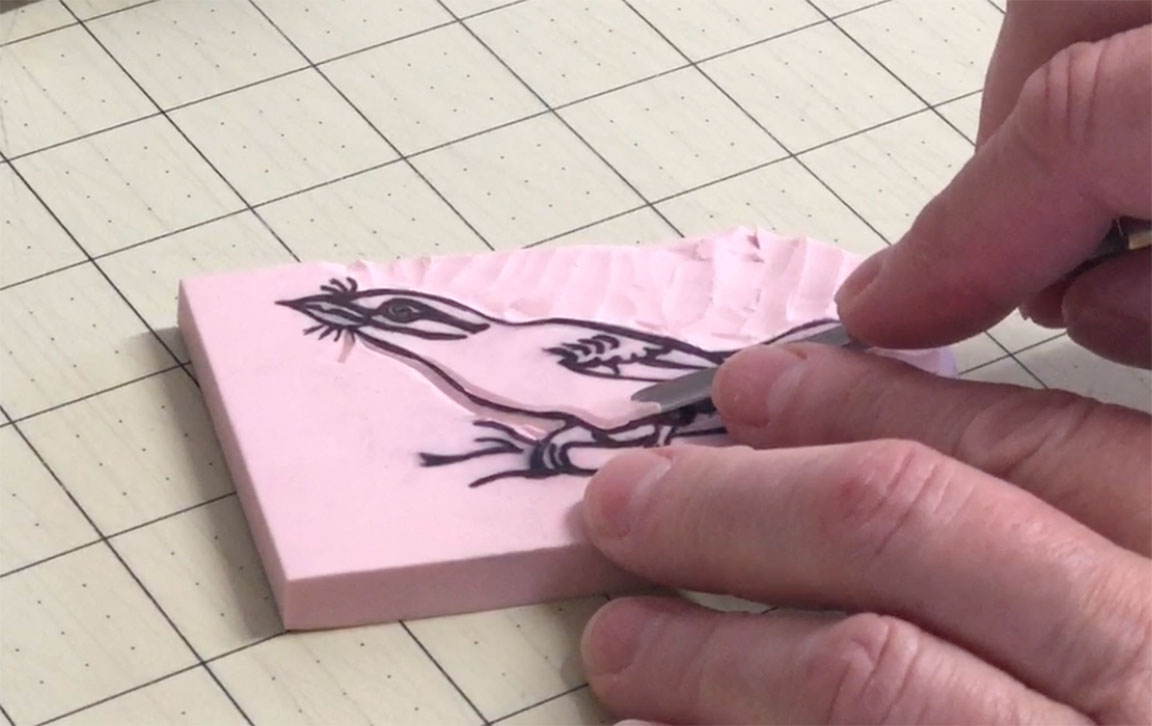

Example 3: The Artistic Texture Stamp. This is a unique example, perhaps hand-carved from a softer material like linoleum or rubber. The design is likely abstract or textured, and the stamp is used to create unique artistic effects on various surfaces. The ink could be a variety of colors or even a combination of inks, leading to a layered, textured print. The impression on the surface might be subtle or bold, depending on the artist’s intention.

The material’s texture might even add an additional layer of interest to the final artwork.

Visual Differences Between New and Worn Stamps

The difference between a print from a brand-new stamp and a worn-out one is striking. A new stamp produces a crisp, sharply defined image with even ink distribution and full color intensity. The lines are clean, and there’s no noticeable blurring or fading. In contrast, a worn-out stamp produces a faint, blurry impression. The ink distribution is uneven, leading to lighter areas and potential smearing.

The color intensity is significantly reduced, and the details of the design might be lost entirely. The edges of the print may become fuzzy and indistinct.

Industries Utilizing Rubber Stamps

The applications of rubber stamps span a broad spectrum of industries. Their reliability and versatility make them an integral part of many business processes.

Below is a list highlighting five different industries and their specific rubber stamp needs:

- Postal Services: Require high-volume, durable stamps for postmarking and cancellation.

- Legal Firms: Utilize stamps for authentication, sealing documents, and creating official records.

- Manufacturing: Employ stamps for product identification, quality control, and inventory tracking.

- Retail: Use stamps for pricing, promotions, and receipts.

- Art and Craft: Utilize stamps for creating unique textures and designs on various materials.

The journey into the world of rubber stamp printing reveals a surprising depth and complexity. What begins as a simple question – “A rubber stamp creates what type of print?” – unfolds into a rich tapestry of materials, techniques, and results. From the crisp clarity of a newly inked stamp to the subtle fading of a well-loved one, each print tells a story, a testament to the enduring legacy of this versatile and often overlooked tool.

Understanding the nuances of rubber stamp printing allows us to appreciate the artistry and precision involved in creating these seemingly simple, yet remarkably expressive, impressions.

FAQ Explained

Can I refill a self-inking stamp?

Yes, many self-inking stamps are refillable. Check the manufacturer’s instructions for specific refill procedures.

How do I clean a rubber stamp?

Clean stamps with a damp cloth and mild soap. For stubborn ink, use a stamp cleaner specifically designed for your stamp type.

What is the best type of rubber stamp for frequent use?

Pre-inked stamps are generally best for high-volume use due to their durability and consistent ink application.

How long does rubber stamp ink typically last?

This varies greatly depending on the ink type, frequency of use, and storage conditions. Some inks can last for years, while others may require refilling more frequently.

Can I make my own rubber stamp?

Yes, you can create custom rubber stamps using various methods, including carving your own design into rubber or using digital printing techniques.