What is a stamping plant? Think massive machines, sheets of metal, and the rhythmic clang of presses—that’s the essence of it. These plants are the unsung heroes behind countless products we use daily, from car parts to electronics. They’re where raw materials are transformed into precise shapes through a powerful process called stamping, a crucial part of modern manufacturing.

Stamping plants utilize various techniques, like blanking, punching, bending, and drawing, to create intricate components. The process involves feeding large sheets of metal (often steel or aluminum) into powerful presses that shape the material with incredible speed and precision. These plants are complex operations, balancing powerful machinery, skilled labor, and rigorous quality control to deliver high-volume production.

Definition and Overview of a Stamping Plant: What Is A Stamping Plant

A stamping plant is a manufacturing facility specializing in the mass production of metal parts through a process called stamping. This involves shaping sheet metal using specialized presses and dies. The fundamental purpose of a stamping plant is to efficiently and cost-effectively create a wide variety of metal components for numerous industries, from automotive and appliances to electronics and construction.

The precision and speed of stamping make it ideal for high-volume production runs.

Stamping Processes Used in Stamping Plants

Several distinct stamping processes are employed in stamping plants, each tailored to achieve specific shapes and functionalities. The choice of process depends on factors such as material thickness, desired complexity, and production volume. These processes offer flexibility in creating a wide array of components.

- Blanking: Cutting a specific shape from a sheet of metal.

- Punching: Creating holes or other cutouts in a sheet metal part.

- Bending: Forming a sheet into a desired angle or curve.

- Embossing: Creating raised or indented designs on the metal surface.

- Coining: Producing highly precise shapes with sharp details.

- Deep Drawing: Forming a cup-shaped or similar three-dimensional part from a flat sheet.

- Progressive Die Stamping: A series of stamping operations performed sequentially in a single die, creating a complete part in one pass.

Machinery Found in a Stamping Plant

Stamping plants house a diverse range of sophisticated machinery designed for precision and high-volume production. The core of the operation centers around powerful presses, supported by ancillary equipment that ensures smooth workflow and high-quality output.

- Presses: These are the heart of the stamping plant, applying force to shape the metal. Different types of presses, discussed below, are used depending on the application and desired precision.

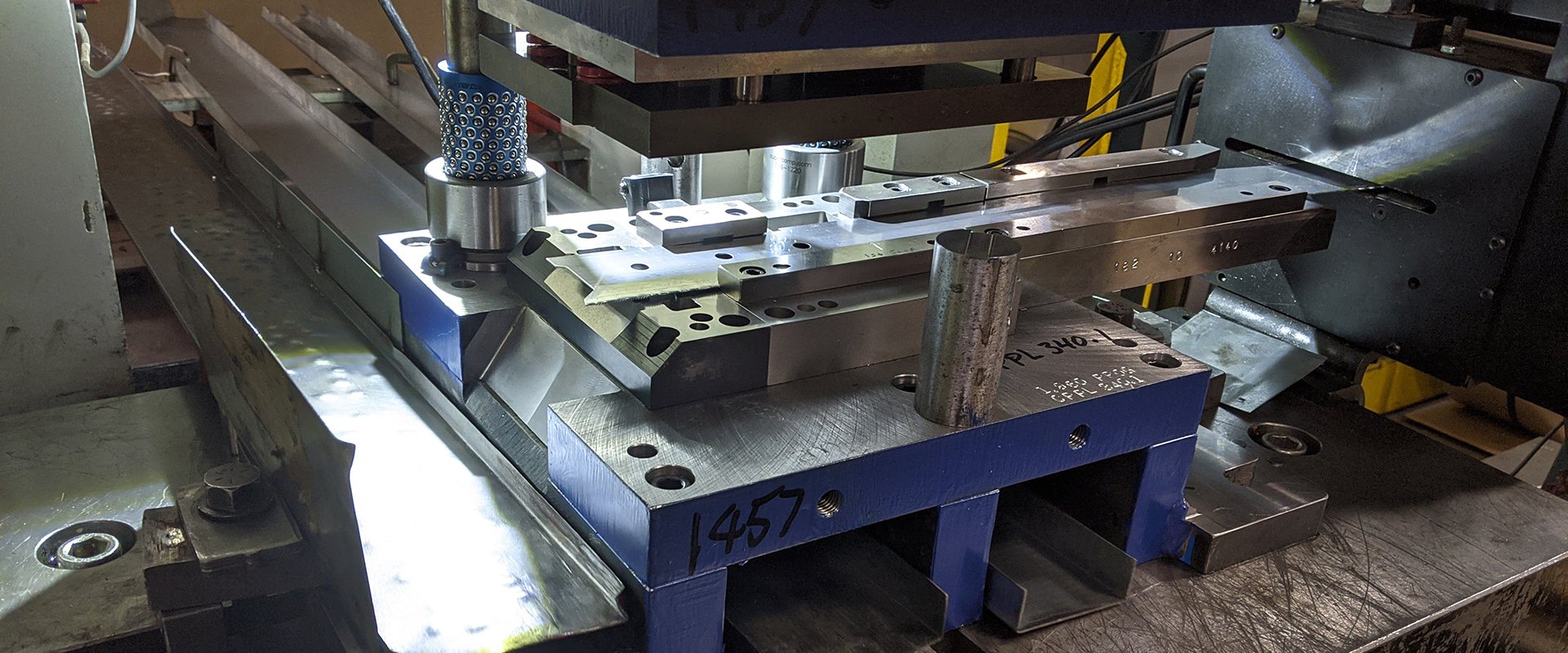

- Dies: These tools, made of hardened steel, define the shape of the stamped part. Dies are precision-engineered to match the specifications of the final product.

- Feeders: These automated systems precisely position and feed sheets of metal into the press, ensuring consistent part production.

- Uncoilers: These unwind large coils of sheet metal, providing a continuous supply for the stamping process.

- Robots and Automation Systems: These are often integrated to handle parts, load and unload presses, and perform other tasks to improve efficiency and safety.

- Quality Control Equipment: This includes measuring devices, vision systems, and other tools to ensure the stamped parts meet the required specifications.

Comparison of Stamping Press Types, What is a stamping plant

The selection of a press type is crucial for optimal performance and cost-effectiveness in a stamping plant. Each type offers distinct advantages and disadvantages.

| Press Type | Speed | Precision | Cost |

|---|---|---|---|

| Mechanical | High | Moderate | Lower |

| Hydraulic | Moderate | High | Higher |

| Servo | Variable, often high | Very High | Highest |

Raw Materials and Production Process

Stamping plants transform raw materials into a wide variety of finished products through a series of precise and powerful processes. Understanding the materials used and the stages of production is crucial to appreciating the complexity and efficiency of these facilities. The selection of raw materials and the precision of the manufacturing process directly impact the final product’s quality, durability, and cost-effectiveness.The heart of a stamping plant lies in its ability to efficiently transform sheet metal into intricate shapes.

This transformation is achieved through a series of precisely coordinated steps, from the initial handling of raw materials to the final inspection of the finished product. The entire process demands sophisticated machinery, skilled operators, and rigorous quality control measures.

Common Raw Materials

Stamping plants primarily utilize sheet metal as their raw material. The specific type of metal chosen depends on the desired properties of the final product, including strength, durability, weight, and cost. Common materials include various grades of steel, aluminum alloys, and occasionally other metals like brass or stainless steel. Steel offers high strength and durability, making it suitable for automotive parts and heavy-duty applications.

Aluminum alloys provide a lighter-weight alternative, ideal for applications where weight reduction is critical, such as aerospace components. The selection process considers factors like material thickness, surface finish requirements, and the complexity of the stamping operation.

Stages in the Stamping Process

The stamping process involves several key stages. First, the raw material, typically in coil form, is unwound and fed into a press. This unwinding and feeding process is crucial for maintaining consistent material flow and minimizing downtime. The coil is then straightened and leveled to ensure a consistent thickness across the entire sheet, which is essential for accurate stamping. Next, the sheet metal is precisely cut to the desired dimensions using a blanking die.

This stage accurately shapes the metal into the required form. The blanked metal is then transferred to a series of stamping presses where various dies progressively form the metal into the final shape. These dies are meticulously designed and manufactured to achieve high precision and repeatability. After the stamping operations, the parts undergo trimming and other secondary operations to remove excess material or refine the edges.

Finally, the finished parts undergo quality inspection before packaging and shipment.

Quality Control Measures

Maintaining high quality throughout the stamping process is paramount. Several quality control measures are implemented at each stage. These measures ensure consistent product quality and minimize defects. For instance, during material handling, the thickness and surface quality of the incoming coils are checked to ensure they meet specifications. During the stamping process, regular checks on die alignment and press parameters are performed to prevent dimensional errors.

Automated inspection systems, often using vision systems or laser scanning, are used to identify defects such as scratches, dents, or dimensional inaccuracies. Statistical Process Control (SPC) charts are utilized to track key process parameters and identify potential problems before they lead to significant defects. Finally, a thorough final inspection verifies that the finished parts meet all specified requirements before they are released for shipment.

Production Flowchart

[Imagine a flowchart here. The flowchart would begin with “Raw Material (Coil)”, then branch to “Unwinding & Leveling,” followed by “Blanking,” then “Progressive Stamping,” then “Trimming/Secondary Operations,” then “Quality Inspection,” and finally “Packaging & Shipping.” Arrows would connect each stage, indicating the flow of materials. Feedback loops could be added to represent quality control checks at each stage, potentially leading to adjustments in earlier stages if necessary.

The flowchart would visually represent the sequential nature of the process and the integration of quality control throughout.]

Types of Stamped Products and Applications

Stamping is a highly versatile metal forming process, capable of producing a vast array of components with intricate shapes and high precision. The applications of stamped products are incredibly diverse, spanning numerous industries and impacting our daily lives in countless ways. This section explores the wide range of products manufactured through stamping, categorizes them by application, and compares stamping to alternative manufacturing methods.Stamping offers significant advantages over processes like casting and machining, particularly in terms of speed, precision, and cost-effectiveness for high-volume production.

However, it does have limitations, primarily concerning material thickness and complexity of design. The choice of manufacturing process depends heavily on the specific product requirements, desired volume, and material properties.

Automotive Stamped Products

The automotive industry is a major consumer of stamped parts. These parts often require high strength and durability to withstand the rigors of vehicle operation. Examples include body panels (doors, hoods, fenders), chassis components, and various smaller interior and exterior trim pieces. The high-volume production requirements of the automotive industry make stamping an ideal choice due to its speed and efficiency.

The precision of stamping ensures consistent part quality and fit, crucial for assembly line efficiency.

Electronic Stamped Products

The electronics industry utilizes stamping for producing a wide variety of components, often requiring intricate designs and high precision. Examples include housings for electronic devices (computers, phones, appliances), heat sinks, and various internal components. The ability of stamping to create complex shapes and features within a single operation makes it a cost-effective solution for mass production of these items.

The thin gauge materials often used in electronics manufacturing are well-suited to stamping.

Household Appliance Stamped Products

Stamping plays a vital role in the manufacture of household appliances, providing components that need to be both durable and aesthetically pleasing. Examples include refrigerator panels, washing machine tubs, and oven components. The ability to create complex shapes and surface finishes through stamping allows manufacturers to create visually appealing and functional products. The strength and durability of stamped components are essential for ensuring the longevity and reliability of these appliances.

Comparison of Stamping with Other Manufacturing Processes

Stamping, casting, and machining represent distinct manufacturing approaches, each with its own strengths and weaknesses. Stamping excels in high-volume production of relatively thin, sheet metal parts with complex shapes, offering superior speed and cost-effectiveness compared to machining. Casting, on the other hand, is suitable for creating complex three-dimensional shapes in various materials, but it often requires secondary machining operations for finishing.

Machining provides high precision and flexibility for creating individual or low-volume parts from a wide range of materials, but it is significantly slower and more expensive than stamping for mass production.

Examples of Diverse Stamped Products

- Automotive Fender: This large, complex part requires deep drawing and multiple stamping operations to achieve its curved shape and precise features. The steel sheet is progressively formed using a series of dies, each shaping the metal closer to the final design. Precise tolerances are crucial to ensure proper fit and alignment with other body panels.

- Electronic Device Housing: These housings often involve intricate designs with cutouts, embossed features, and precise bends. The material, typically thin sheet metal or aluminum, is stamped using a series of dies to create the complex shape and features. Surface finishing, such as painting or powder coating, is often applied after stamping.

- Refrigerator Door Panel: This large, flat panel requires precise stamping to achieve its smooth, even surface and accurate dimensions. The steel sheet is formed using a series of dies, ensuring consistent quality and fit. The panel’s surface may undergo additional processes, such as painting or applying a protective coating, to enhance its appearance and durability.

Safety and Environmental Considerations

Stamping plants, while highly efficient in metal forming, present unique safety and environmental challenges. The high-speed machinery, heavy materials, and potential for airborne pollutants necessitate robust safety protocols and environmentally conscious practices. Adherence to these standards is crucial for protecting both workers and the surrounding environment.

Safety in stamping plants centers on preventing accidents stemming from the inherent risks of heavy machinery and sharp materials. Environmental concerns primarily revolve around minimizing waste, reducing energy consumption, and controlling pollutant emissions. Implementing effective safety and environmental management systems is not only ethically responsible but also contributes to improved productivity and reduced operational costs.

Safety Protocols and Regulations

Stamping plants operate under stringent safety regulations designed to minimize workplace hazards. These regulations typically cover machine guarding, lockout/tagout procedures, personal protective equipment (PPE), emergency response plans, and regular safety training. Machine guarding involves physical barriers and safety interlocks to prevent accidental contact with moving parts. Lockout/tagout procedures ensure that machinery is properly de-energized before maintenance or repair. PPE, including safety glasses, gloves, hearing protection, and steel-toed boots, is mandatory for all personnel.

Comprehensive emergency response plans, including evacuation procedures and first aid protocols, are essential. Regular safety training keeps employees informed of potential hazards and proper safety procedures. Failure to comply with these regulations can result in serious injuries, production delays, and legal penalties. Specific regulations vary by location and are enforced by relevant occupational safety and health agencies.

Environmental Impact and Mitigation Strategies

Stamping operations generate various environmental impacts, including air pollution from lubricants and coolants, noise pollution from machinery, wastewater from cleaning processes, and solid waste from scrap metal and packaging. Mitigation strategies focus on reducing these impacts through technological advancements and operational changes. For instance, implementing closed-loop systems for lubricants and coolants minimizes waste and prevents environmental contamination. Noise reduction can be achieved through soundproofing and the use of quieter machinery.

Wastewater treatment systems are crucial for removing contaminants before discharge. Recycling programs for scrap metal significantly reduce landfill waste and conserve valuable resources. Furthermore, energy-efficient equipment and practices contribute to lowering the plant’s carbon footprint. Adopting cleaner production methods and investing in advanced pollution control technologies are essential for minimizing environmental impact.

Best Practices for Waste and Energy Reduction

Several best practices can significantly reduce waste and energy consumption in a stamping plant. These include optimizing the stamping process to minimize material usage, implementing lean manufacturing principles to streamline operations and reduce waste, utilizing energy-efficient equipment, such as servo presses and high-efficiency lighting, and investing in automated material handling systems to reduce energy consumption associated with manual material movement.

Regular maintenance of equipment ensures optimal efficiency and reduces energy waste. Implementing a robust recycling program for scrap metal and other materials reduces waste sent to landfills. Furthermore, training employees on energy-saving practices can further enhance efficiency and sustainability efforts. Regular audits and monitoring of energy and resource consumption provide valuable data for continuous improvement. A comprehensive environmental management system (EMS) is crucial for effectively tracking and managing environmental performance.

Potential Environmental Hazards and Safety Measures

Addressing potential environmental hazards requires a proactive approach incorporating specific safety measures. The following list details some key hazards and their corresponding mitigation strategies:

- Noise Pollution: Implementation of noise barriers, regular hearing tests for employees, and use of hearing protection.

- Airborne Pollutants (oils, coolants): Use of closed-loop systems, local exhaust ventilation, and air filtration systems.

- Wastewater Contamination: Implementation of wastewater treatment plants, regular monitoring of effluent quality, and adherence to discharge permits.

- Scrap Metal Waste: Establishment of robust recycling programs, optimized material usage, and partnerships with scrap metal recyclers.

- Energy Consumption: Use of energy-efficient equipment, process optimization, and implementation of energy management systems.

Technological Advancements and Automation

The modern stamping plant is a marvel of engineering, leveraging advanced technologies to achieve unprecedented levels of efficiency, precision, and productivity. Automation and robotics have revolutionized the industry, transforming what was once a labor-intensive process into a highly automated and streamlined operation. This section explores the significant role of these advancements in enhancing the capabilities and competitiveness of stamping plants.The integration of automation and robotics significantly improves the speed, accuracy, and consistency of stamping operations.

Advanced technologies like computer-aided design (CAD) and computer-aided manufacturing (CAM) play crucial roles in optimizing the entire process, from initial design to final production. This results in reduced production times, minimized waste, and improved overall quality of stamped products.

The Role of Automation and Robotics in Modern Stamping Plants

Automation in stamping plants encompasses a wide range of technologies, from robotic arms performing intricate press operations to automated material handling systems that seamlessly transport parts throughout the production line. Robotic systems offer significant advantages over manual labor, particularly in tasks requiring high precision, repetitive movements, or operation in hazardous environments. For example, robotic welders can precisely join stamped parts with consistent quality, while automated transfer systems minimize human intervention and the associated risks of workplace accidents.

The use of vision systems integrated with robots enables real-time quality control, automatically rejecting defective parts and ensuring consistent output quality. This automation not only increases production speed but also improves product consistency and reduces the likelihood of human error.

Benefits of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM)

CAD software allows engineers to design and refine stamping dies and parts virtually, significantly reducing lead times and costs associated with physical prototyping. Through simulations and analyses, potential design flaws can be identified and corrected before physical production begins. CAM software translates the CAD designs into instructions for automated machinery, optimizing tool paths and minimizing material waste. This integration of CAD/CAM enhances design flexibility, allowing for rapid prototyping and iterative design improvements.

A company designing a new car part, for example, could use CAD to create a virtual model, then use CAM to program the stamping press to produce the part with minimal adjustments needed during physical production.

Examples of Innovative Technologies for Improved Efficiency and Precision

Several innovative technologies are transforming stamping plant operations. High-speed presses equipped with advanced control systems allow for faster cycle times and higher production rates. Laser cutting and trimming offer increased precision and reduced material waste compared to traditional methods. Advanced die technologies, such as progressive dies, allow for multiple operations to be performed in a single stroke, increasing overall efficiency.

Furthermore, the implementation of digital twins, virtual representations of physical processes, allows for simulations and predictive maintenance, minimizing downtime and optimizing production schedules. For instance, a company using a digital twin of its stamping press can simulate different operating parameters to identify the optimal settings for maximum efficiency and minimal wear and tear on the equipment.

Automation’s Contribution to Increased Productivity and Reduced Production Costs

The implementation of automation in stamping plants directly contributes to increased productivity and reduced costs. Automated systems operate continuously, eliminating downtime associated with human breaks and shift changes. They also reduce labor costs and minimize material waste, resulting in significant savings. Furthermore, automation improves product quality and consistency, reducing the need for rework and scrap. A study by the National Institute of Standards and Technology (NIST) showed that automation in manufacturing processes, including stamping, can lead to a 20-30% increase in productivity and a 10-15% reduction in production costs.

These improvements significantly enhance the profitability and competitiveness of stamping plants in the global market.

So, what have we learned? Stamping plants are essential to modern manufacturing, quietly churning out the parts that make up so much of our world. From the simple to the complex, the process is a testament to human ingenuity and industrial might. Understanding their role—the raw materials, the machinery, the safety protocols—helps us appreciate the intricate web of processes that bring everyday products to life.

Next time you see a car, a laptop, or even a simple can, remember the power and precision of the stamping plant that helped create it.

FAQ Insights

What are the biggest safety concerns in a stamping plant?

Major safety concerns include moving machinery, sharp edges, and potential for injury from flying debris. Strict safety protocols and personal protective equipment (PPE) are crucial.

How much does it cost to set up a stamping plant?

Setting up a stamping plant is a major investment, varying wildly based on size, capacity, and the type of presses and automation used. Millions of dollars are typically involved.

What kind of jobs are available in a stamping plant?

Jobs range from machine operators and maintenance technicians to engineers, quality control specialists, and management roles. Skills in mechanics, automation, and quality control are highly valued.

What’s the environmental impact of stamping?

Stamping can generate noise pollution, waste materials (scrap metal), and energy consumption. Modern plants focus on minimizing these impacts through recycling, efficient machinery, and environmentally friendly practices.